XIAMEN YINTAI MACHINERY CO., LTD. |

|

Verified Suppliers

|

|

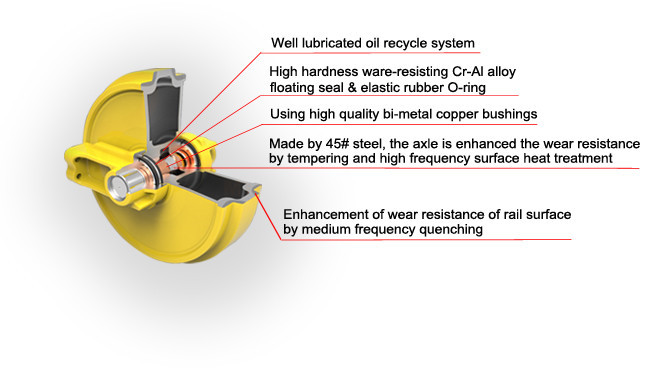

Idlers guide the track in and out of the track rollers. They intermittently support the machine's weight and provide a way to control track slack and tension. The splined connection between idler and shaft provides more bearing area and better torque transfer, increasing reliability and matching idler life with that of other lower works components. Rotating shaft within stationary bushings produces less contact stress and wear. Longer crawler system life increases change-out intervals reducing employee exposure to safety risks.

Reduces bearing stress 50% to decrease bearing loads and increase component life

Heavy-duty rock guards protect against damage from dirt and debris

Helps to lower mine operating costs by extending crawler system life, minimizing unplanned downtime

Provides greater track efficiency by increasing bearing area and lube distribution

Splined connection between idler and shaft increases reliability and matches idler life with that of other lower works components

Bearing blocks with bushings can be removed without breaking the track

Dedicated lube injectors supply lubricant to critical wear surfaces

50% less bearing stress reduces bearing loads and increases component life

Rotating shaft within stationary bushings produces less contact stress and wear

Heavy-duty rock guard prevents dirt and debris from damaging parts

Longer crawler system life increases change-out intervals reducing employee exposure to safety risks from system change-outs and component replacement

* World-class quality

* Factory sale directly with reasonable price

* 35 years experience in Excavator & Bulldozer spare parts manufacturing

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* Professional sales team, quality inspection and report, maritime logistics guidance

* After-sale services: video technical support, 24h online support