K&M TechnologiesCo., Ltd |

|

20kHz Super Precision Servo Ultrasonic Welding Machine With Advanced 7 Welding Modes

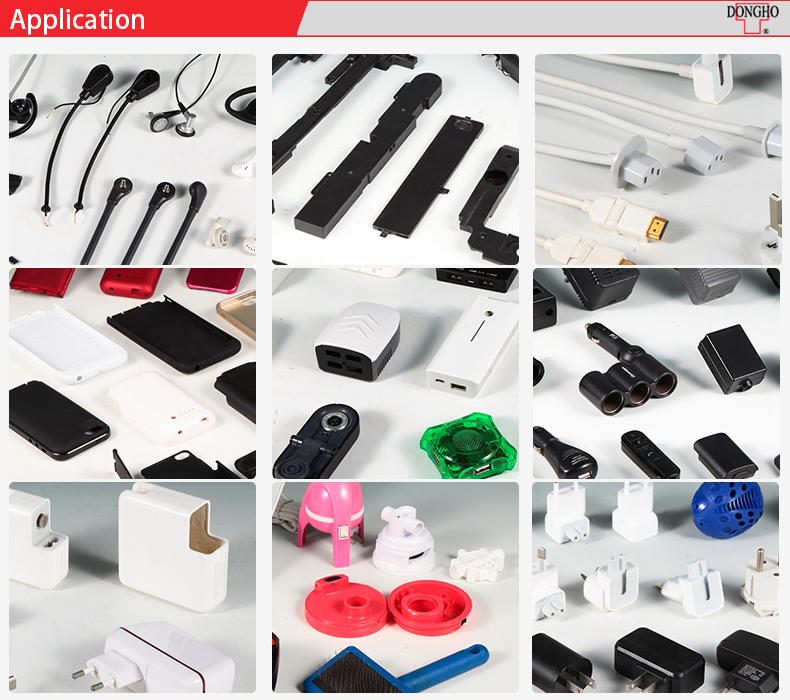

The new iSF series precision servo ultrasonic welding machine can appreciate DONGHO's innovative capabilities, diversified expansion of the iQS operating system, visual innovation to support the vision system, data connection to support industry 4.0 applications, IDCS interconnection services to support remote monitoring and collection. ISF series welding smart activation provides solutions to improve welding accuracy, control, and efficiency, ensure welding quality and improve employee operation efficiency and product production efficiency.

Technical Parameters:

| Model | iSF S2040e |

| Frequency accuracy | 19.80KHz-20.20KHz |

| Power | 4000W |

| Triggering Method | Position/Pressure/Pressure drop |

| Welding Method | Weld time/relative position/absolute position/ weld energy/peak power/Max.pressure/grounding detect |

| Effective stroke(mm) | ≤95mm |

| Max Welding Time | 5 S |

| Voltage(V) | AC220V±5% 50/60Hz |

| Amplitude control | Single-stage amplitude/stepping amplitude/distance amplitude |

| Piling function | Time /position/energy/pressure |

| Operation way | standard/multi-speed(9-speed) |

| Cooling system | Vortex cooler |

| Weld area | No more than 250mm as per material, shape, etc. |

| Dimension(L*W*H)mm | 400*670*1610mm |

| Weight(kg) | 105KG |

Features:

* The 6th generation iQS operating system

* 9-stage speed and pressure control

* With new type weighing sensor

* With superposition function

* Quality QA diagnostic control

* Built-in scanning gun for data tracing

* USB-saved welding parameters

* Intelligent functions and technologies

Advantages of servo ultrasonic welding machine:

Conventional ultrasonic equipment, driven by air cylinders, cannot meet the new trend of high precision and high repeatability required for welding these smaller, more delicate parts. Therefore, the servo ultrasonic welding machine came into being. The key feature of the servo drive ultrasonic welder is that it enables more accurate and sensitive pressure adjustment throughout the welding process. Welding pressure is necessary to ensure adequate contact between the welding head and the product and to effectively transfer ultrasonic energy. For the welding of small medical parts, the welding bar height is designed to be very small in order to reduce the overflow as much as possible. Servo ultrasonic welding can fully melt the welding bar in a long enough welding time with very small and precise pressure. For transparent PC welding, there are often bubbles, and after using servo ultrasonic welding machine equipment, through the rapid and accurate adjustment of welding pressure, eliminate bubbles. High-quality welds have been produced. The high precision of the servo welding machine ensures the quality and greatly improves the production efficiency.