Mitech CO.,LTD. |

|

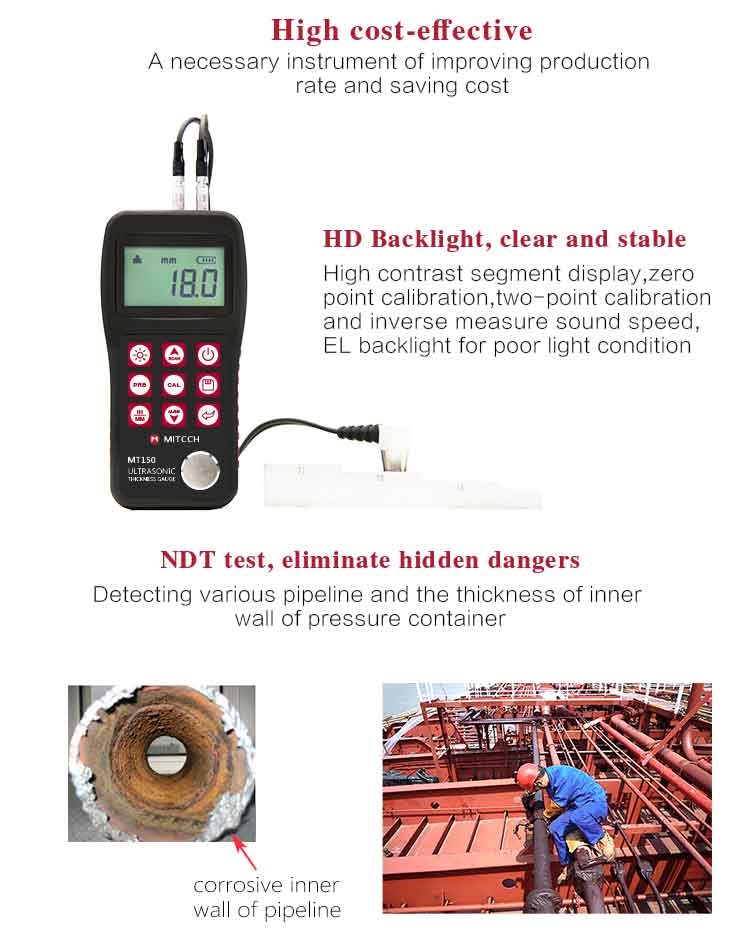

MITECH MT150 NDT Digital Ultrasonic Thickness Gauge With High Precision

Overview

The model MT150 is a digital ultrasonic thickness gauge. Based on the principle of ultrasonic principle, the instrument is capable of measuring the thickness of various materials, such as metal, plastic, ceramic, glass and many other good ultrasonic conductors. It of all kinds of materials. Compared with the traditional measurement methods, the advantages of ultrasonic thickness gauge is exposed to one side of the workpiece to complete the measurement. Its unique non-destructive testing performance provide the perfect solution for the thickness testing of closed pipes, containers, etc. It is widely used in pertroleum , chemical ,metallurgy, shipbuilding, aviation, aerospace and other fields because of monitoring corrosion thinning degree of various pipes and pressure vessels. It can also be used for precise measurement of sheet metal and machined parts.

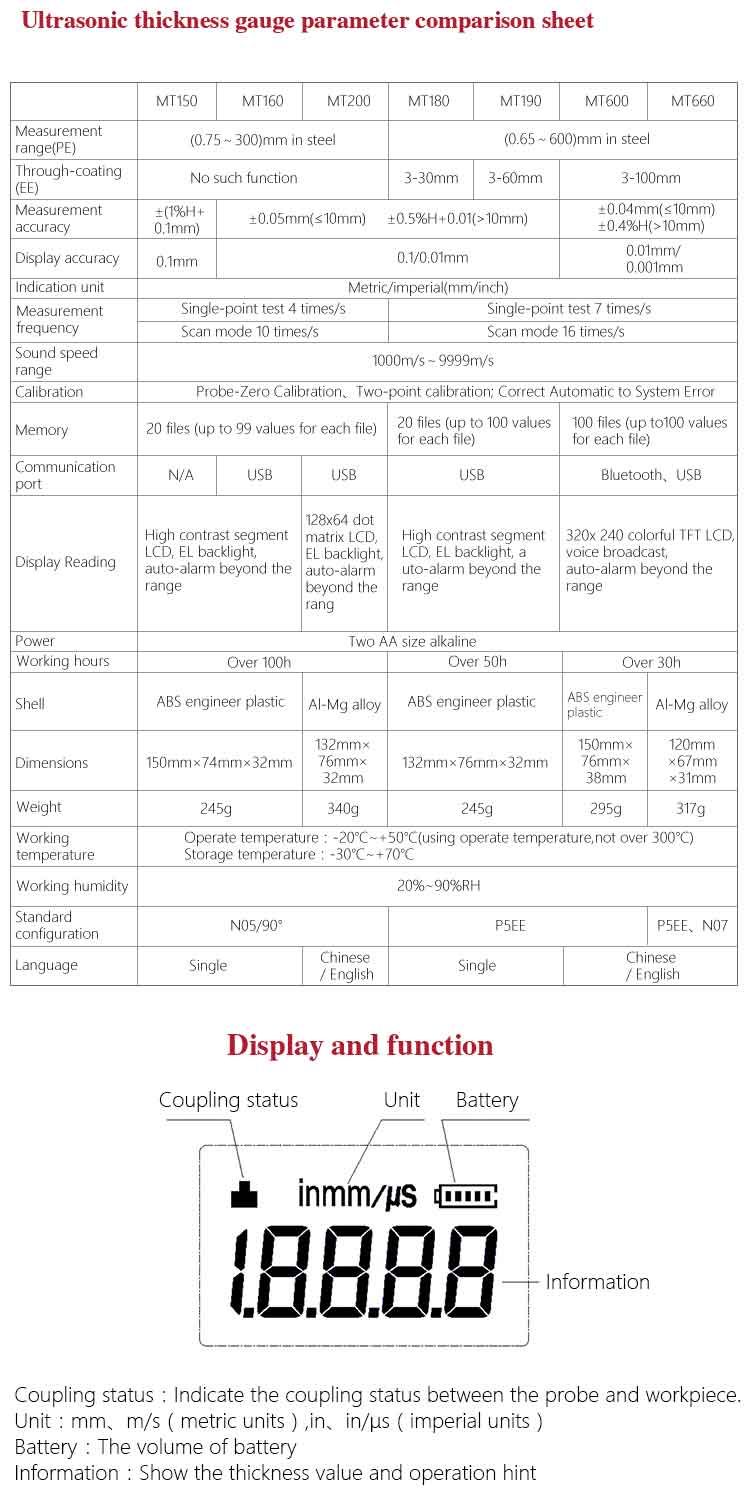

Technical Parameters

| Display | 4.5 digits LCD with EL backlight |

| Measuring Range | (0.75~300)mm (in Steel) |

| Sound Velocity Range | (1000~9999) m/s |

| Resolution | 0.1mm |

| Accuracy | ±(0.5%Thickness+0.04)mm, depends on materials and conditions |

| Units | Metric/Imperial unit selectable |

| Measurement Frequency | Four measurements readings per second for single point measurement, and ten per second for Scan Mode |

| Storage | Memory for up to 20 files (up to 99 values for each file) of stored values |

| Thickness Measurement Modes | Single point thickness measurement and scanning thickness measurement |

| Power Source | Two “AA” size, 1.5 Volt alkaline batteries  |

| Operating Time | More than 100 hours (EL backlight off) |

| Communication | No |

| Outline Dimension | 150mm×74mm×32 mm |

| Weight | 245g |

Features

Working Principle

The digital ultrasonic thickness gauge determines the thickness of a part or structure by accurately measuring the time required for a short ultrasonic pulse generated by a transducer to travel through the thickness of the material, reflect from the back or inside surface, and be returned to the transducer. The measured two-way transit time is divided by two to account for the down-and-back travel path, and then multiplied by the velocity of sound in the material. The result is expressed in the well-known relationship.

Where:

H-Thickness of the test piece.

v-Sound Velocity in the material.

t-The measured round-trip transit time.

To make sure the probe working properly, it needs to use couplant to isolate the air between the probe surface and the measured workpiece surface. The liquid used for the coupling between the probe and workpiece is called as couplant.

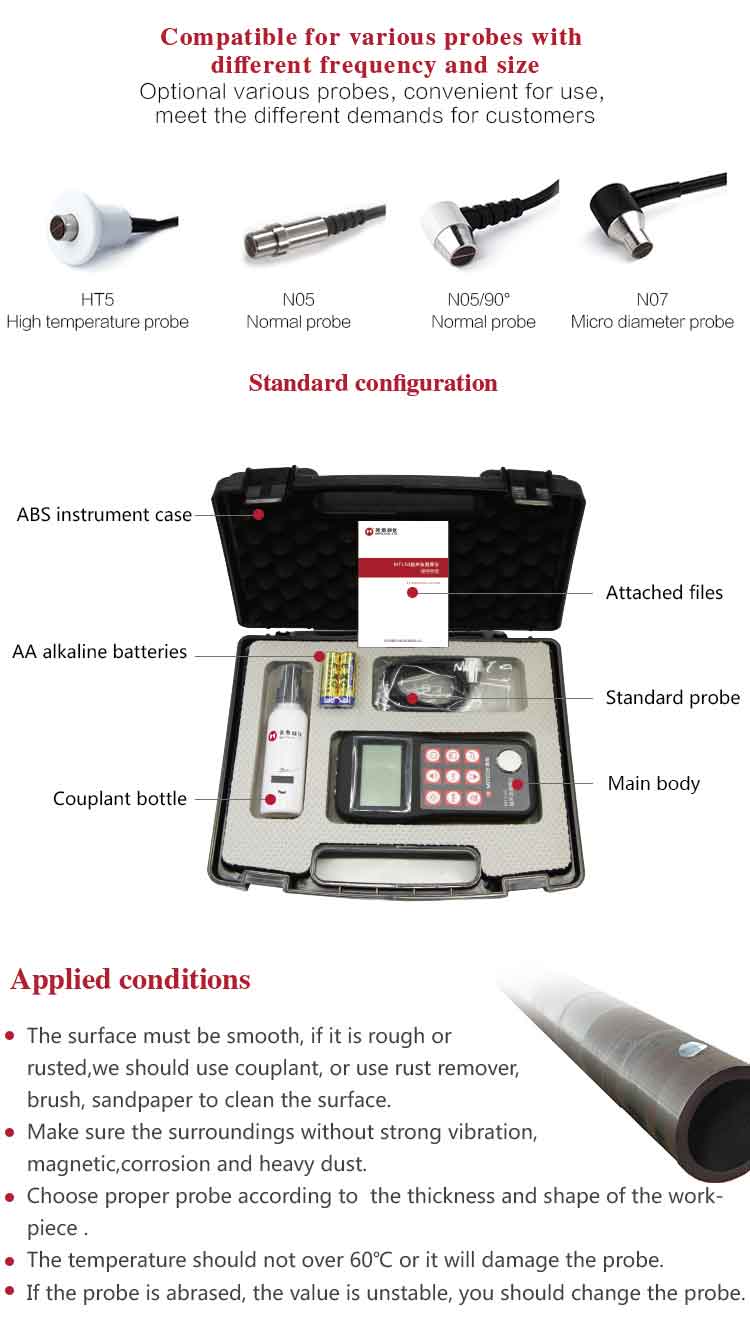

Configuration

Standard Configuration | No. | Item | Quantity | Note |

| 1 | Main body | 1 | ||

| 2 | Probe: N05 | 1 | ||

| 3 | Couplant | 1 | ||

| 4 | Instrument Case | 1 | ||

| 5 | Operating Manual | 1 | ||

| 6 | Alkaline battery | 2 | ||

Optional Configuration | 1 | Probe: N05/90°(5MHz) | ||

| 2 | Probe: N02(2.5MHz) | |||

| 3 | Probe: N07(7MHz) | |||

| 4 | Probe: HT5(5MHz) | |||

| 5 | High temperature couplant |