Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

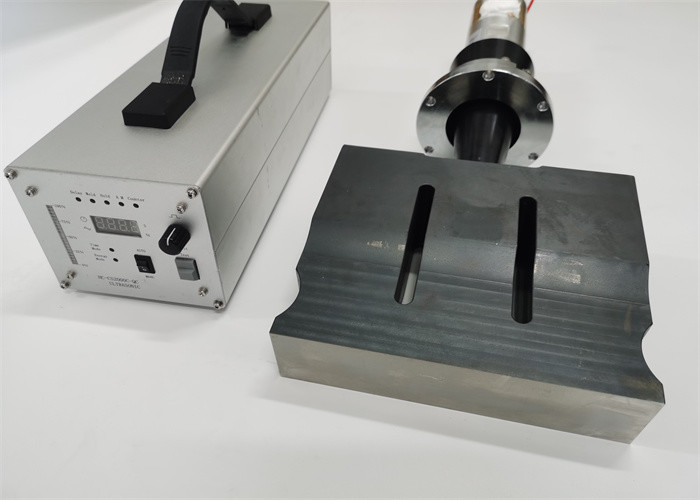

15Khz 2600w High Power Ultrasound Parts for Shrinkable Matreials Welding

Description:

The 15K ultrasonic suture system is mainly used in the medical industry (surgical clothing, hats, shoes), industry (anti-corrosion clothing, electrostatic clothing, filters, headgear), automobile industry (chair cover, head cushion cover) and other industries (suit cover, bath Cap) and so on. Compared with ordinary needle suture, ultrasonic suture does not require needle suture, has the characteristics of high suture strength, good sealing performance, and fast suture speed.

Specifications:

| Classification | QR-15K | QR-20K |

| Frequency | 15Khz | 20Khz |

| Power | 2600w | 1500w |

| Voltage | 220V | 220V |

| Generator | Digital generator | Digital generator |

| Material of Horn | Steel | Steel |

| Dimension of horn | 200*50mm | 110*20mm |

| Net weight of horn | 20kgs | 5.5kgs |

| Dimension of generator | 370*120*110mm | 250*150*300mm |

| Net weight of generator | 2kgs | 6kgs |

| Package | Wooden case | Wooden case |

| Application | Non woven mask welding | Non woven mask welding |

Advantages of seamless stitching of ultrasonic masks:

1. High stability: When the ultrasonic mask is seamlessly stitched, it will not cause stretching, distortion or deformation of the fabric, and the accuracy is extremely high. Due to the hot-melt effect, no need to use needle thread, the product has increased water resistance, lighter weight and easier folding.

2. Welding and cutting synchronization: Ultrasonic mask seamless stitching equipment is not only suitable for continuous stitching, but also can cut textiles while welding, and realize automatic edge banding.

3. No heat radiation: When the ultrasonic mask is stitched, the energy penetrates the material layer for welding. There is no heat radiation. During the continuous stitching process, the heat will not be transferred to the product, which is especially beneficial for the packaging of heat-sensitive products.

Weld seam can be controlled: the fabric passes under the traction of the welding head and the pressure wheel, and the fabric is welded using ultrasound. The pressure wheel can be changed to change the size and embossing of the weld seam, which is more flexible and convenient.

15Khz 2600w High Power Ultrasound Parts for Shrinkable Matreials Welding