|

|

[China]

Trade Verify

Address: No. 196 Shitashang Qiufeng Village, Fuchun Subdistrict, Fuyang District, Hangzhou City, Zhejiang Province, China. 311400

Contact name:Tina

Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

High Power 3600w 15Khz Ultrasonic Welding Transducer with Yellow Ceramics

Description:

As we all know, ultrasonic transducers are the core components of many ultrasonic devices such as ultrasonic shearing machines, ultrasonic hot drilling machines, and ultrasonic masking machines. Their main function is to generate ultrasonic waves and convert them into mechanical vibration energy.

The main consideration for using ultrasonic transducers is the matching with the input and output, followed by the mechanical mounting and mating dimensions. The frequency of the transducer is relatively straightforward. The frequency refers to a frequency measured by a transmission line method using a frequency (function) generator, a millivoltmeter, an oscilloscope, or the like, or a frequency measured by a network impedance analyzer or the like. Generally known as the small signal frequency. The customer connects the ultrasonic transducer to the drive power supply via a cable, and the actual operating frequency measured when the power is applied after no load or load. Because the customer matching circuits are different, the same ultrasonic transducers exhibit different frequencies at different driving power sources. Such frequencies cannot be used as a basis for discussion.

Specifications:

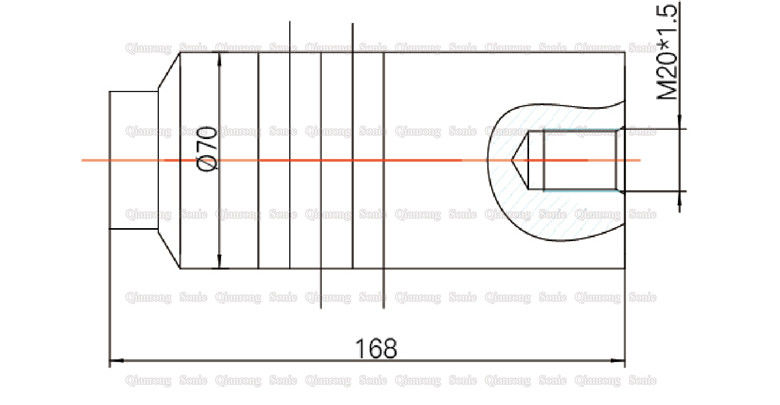

| Model | QR-7015-4BZ |

| Frequency | 15 khz |

| Output power | 3600 watt |

| Joint bolt | M20*1.5 |

| Ceramic disc Diameter | 70mm |

| Qty of ceramic discs | 4pcs |

| Capacitance | 14.5-19nf |

| Amplitude | 10 um |

| Application | Plastic welding machine |

Problems that can arise when using ultrasonic transducers:

Common problems in use are wafer cracking, weakness, overload, electrode pad ignition, electrode chip cracking, heat generation, leakage, and wafer misalignment.

The reasons for such problems can be classified into three categories. One is that the customer's drive power or mold and assembly problems, the second is that our transducers and horns have problems, the third is that both products have no problem, but do not match.

The first case: our ultrasonic transducer and horn have problems

This will happen, but the possibility of discovery is relatively small. Our company specializes in producing all kinds of high-power ultrasonic transducers. The quality of all products of the horn is at a high level in China. At the same time, we have ISO9000 quality certification system and strict process and inspection. The quality of our ultrasonic transducer products is guaranteed. The pass rate of our factory products is 100%.

The second case: the customer's drive power or mold has a problem

We recommend that customers actively find the cause or communicate with our technical staff to improve as soon as possible.

The third case: the products of both parties have no problem, but they do not match.

This is the most common, that is, the customer's drive power is good, the ultrasonic transducer is also good, the assembly is normal, but the parts do not match. The main parameter causing the mismatch is the frequency and capacitance of the ultrasonic transducer. In response to this situation, the solution is to adjust the matching parameters of the driver's power supply to suit our ultrasonic transducers. The second method is to carefully study the various chassis and the original transducers. Parameters, in summary, as long as you can provide accurate parameter requirements, we can guarantee to provide you with the right transducer.

High Power 3600w 15Khz Ultrasonic Welding Transducer with Yellow Ceramics