Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

Repair Ultrasonic Intelligent Frequency Control System Generator 15Khz 4200w

Description:

Ultrasonic generator is a device that converts utility power into a corresponding high-frequency alternating current of a transducer to drive a transducer, and is an important component of a high-power ultrasonic system, and can also be called an electronic box. Ultrasonic drive power supply, ultrasonic controller. Although the ultrasonic generator can also be referred to as an ultrasonic driving power source, in reality, the ultrasonic generator is only a part of the ultrasonic driving power source.

working principle:

An ultrasonic power source, also known as an ultrasonic generator, is a device for generating and providing ultrasonic energy to an ultrasonic transducer. Its purpose is to convert our mains (220V or 380V, 50Hz or 60Hz) into a high-frequency AC signal that can be matched with an ultrasonic transducer. This signal can be either a sinusoidal signal or a pulsed signal.

Specifications:

| Item No | QR-WD15 |

| Power | 4200W |

| Generator | Digital generator |

| Frequency | 15KHZ |

| Voltage | 220V or 110V |

| Size | 300*450*170mm |

| Application | Plastic Welding Machine |

| Net weight | 7Kg |

Troubleshooting when the ultrasonic generator is not working properly:

Ultrasonic equipment uses sound waves to perform work. How do we judge whether the ultrasonic generator is working properly or not when there is a problem with the ultrasonic equipment? First, we turn on the power switch on the ultrasonic power control box, press and hold the sound test button on the power box. When the button is pressed, observe the “amplifier” reading, and then listen to the sound. When the sound is not sharp, the current does not exceed 0.5A (aluminum When the current does not exceed 0.8A (steel mold), it is considered normal.

At the same time, if there is an overload indicator light or a harsh sound, or a hoarse sound, when the welding head is loose or the screw is broken, tighten the welding head or replace the screw to solve the problem. Appears during use, this is not the case with new machines.)

After the button of the sound wave detection is pressed, if the current meter shows that the current is high, there is a power and frequency adjustment switch on the right side of the point box to adjust the power gear position adjustment switch to the desired position (1 is the lowest gear position). The slow twisting FM switch adjusts the current to a minimum. (Under normal adjustment, it has been adjusted to the best condition at the factory)

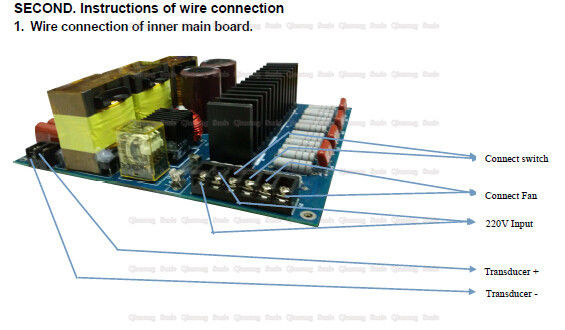

Repair Ultrasonic Intelligent Frequency Control System Generator 15Khz 4200w