Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

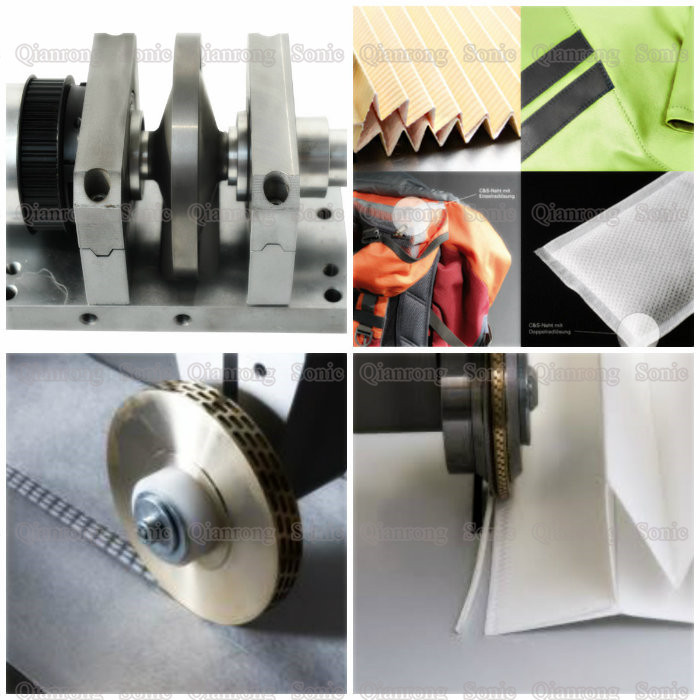

Logitudinal Vibration System for 35Khz 800w Ultrasound Sewing Wheel Welding Machine

Description:

Ultrasonic Sewing Machine-----Ultrasonic welding is a high-tech technology for welding thermoplastic products. Various thermoplastic rubber parts can be processed by ultrasonic welding without adding solvents, adhesives or other auxiliary products. The advantages are increased multi-productivity, reduced costs, improved product quality and safe production. The power adjustment is more precise, the resolution is higher, and the products of various shapes can be satisfied, so as not to damage the product. The ultrasonic transducers are made of high-quality raw materials and precision-machined to make the ultrasonic airflow perfect at every point.

Specifications:

| Item No | QR-S35A |

| Power | 800W |

| Generator | Analog generator |

| Frequency | 35KHZ |

| Voltage | 220V or 110V |

| Width of welding wheel | 11.5mm |

| Matched Transducer | 3535-2D PZT4 |

| Generator size | 250*200*430mm |

Advantages:

Compared to traditional needle-type wire stitching, ultrasonic stitching has the following advantages:

1.Using ultrasonic welding, it avoids the need for needle threading, eliminating the trouble of frequent needle changing. It can also clean and partially cut and seal textiles without the traditional broken wire joints. The stitching also plays the role of decoration, strong adhesion, waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect and high-grade appearance; quality is guaranteed.

2.Using ultrasonic and special steel wheel processing, the edge of the seal will not crack, and it will not hurt the edge of the cloth, and there is no burr or curling.

3. It does not need to be preheated during manufacture and can be operated continuously.

4. The operation is simple, and there is not much difference between the traditional sewing machine operation method, and the ordinary sewing machine can operate.

5. Low cost, 5 to 6 times faster than traditional machines, and high efficiency.

Application:

Environmental protection bags, gift bags, shopping bags, advertising bags, suit bags, advertising aprons, non-woven hand bags, non-woven clothes bags, ultrasonic sewing machines, non-woven bags

Non-woven bags, gift bags, cosmetic bags, net bundles, non-woven computer sets, TV sets, air-conditioning sets, washing machine sets, dust cover sets, pillowcases, shoe covers, high-grade non-woven mattresses, hotels Textile disposables. Non-woven saunas include: sauna suits, bathrobes, bath pants, paper underwear - and other environmentally friendly non-woven products.

Logitudinal Vibration System for 35Khz 800w Ultrasound Sewing Wheel Welding Machine