Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

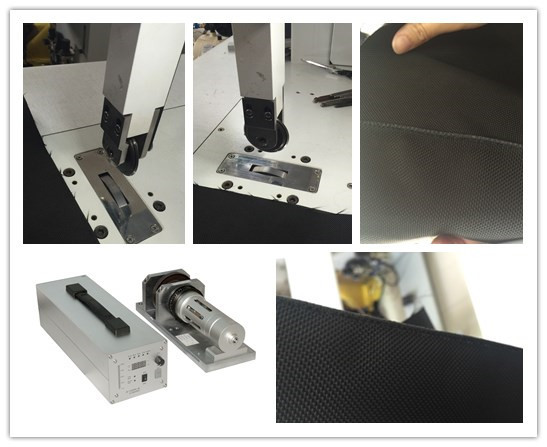

Advance 35Khz Ultrasonic Rotate Steel Wheel Fabric Welding Parts

with Digital Generator

Description:

Ultrasonic rotary vibration is used for fabric stitching and

cutting, and is a newly developed technological achievement in the

world. Hangzhou Qianrong Automation Equipment closely tracks the

new research results of foreign countries and develops ultrasonic

seamless sewing movements. This is the core component of an

ultrasonic seamless sewing machine (also called an ultrasonic

radial sewing machine). It completely solves the inherent problem

of the original ultrasonic longitudinal vibration technology, that

is, the moving direction of the ultrasonic welding head is

inconsistent with the moving direction of the cloth, and is not

synchronized. The precision of ultrasonic cloth stitching has been

greatly improved, making it possible to apply ultrasonic technology

widely in the field of garment stitching. Ultrasonic seamless

sewing has the characteristics of fast welding speed, high

strength, beautiful weld seam, good sealing performance, low energy

consumption and simple operation. It is the development direction

of sewing machine.

Specifications:

| Item No | QR-S35D |

| Power | 1000W |

| Generator | Digital generator |

| Frequency | 35KHZ |

| Voltage | 220V or 110V |

| Width of welding wheel | 11.5mm |

| Matched Transducer | 3535-4D PZT4 |

| Generator size | 250*200*430mm |

Advantages:

Compared to traditional needle-type wire stitching, ultrasonic stitching has the following advantages:

1.Using ultrasonic welding, it avoids the need for needle threading, eliminating the trouble of frequent needle changing. It can also clean and partially cut and seal textiles without the traditional broken wire joints. The stitching also plays the role of decoration, strong adhesion, waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect and high-grade appearance; quality is guaranteed.

2.Using ultrasonic and special steel wheel processing, the edge of the seal will not crack, and it will not hurt the edge of the cloth, and there is no burr or curling.

3. It does not need to be preheated during manufacture and can be operated continuously.

4. The operation is simple, and there is not much difference between the traditional sewing machine operation method, and the ordinary sewing machine can operate.

5. Low cost, 5 to 6 times faster than traditional machines, and high efficiency.

Advance 35Khz Ultrasonic Rotate Steel Wheel Fabric Welding Parts

with Digital Generator