Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

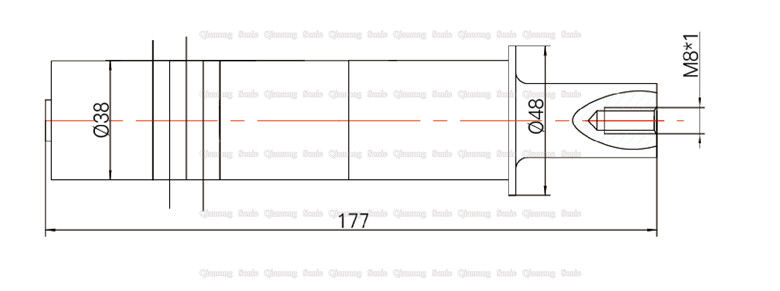

800W 28Khz Ultrasonic Welding Vibration with Aluminum Booster M8 Screw

Description:

The transducers, horns, and horns are designed to be half the wavelength of the ultrasonic frequency at work, so their size and shape are subject to special design; any changes may cause changes in frequency and processing effects, so Professional production. The size will vary depending on the materials used. The materials suitable for ultrasonic transducers, horns and welding heads are: titanium alloy, aluminum alloy, alloy steel, and the like. Since the ultrasonic waves are constantly vibrating at high frequencies, the material requirements are very high and are not affordable for ordinary materials.

Specifications:

| Model | QR-3828-4BZ-BJL |

| Frequency | 28khz |

| Output power | 800 watt |

| Ceramic disc Diameter | 38mm |

| Qty of ceramic discs | 4pcs |

| Capacitance | 7.2-12nf |

| Application | Ultrasonic Plastic Welding machine |

Instruction of Ultrasonic Oscillator:

The ultrasonic oscillator system consists of three parts: Transducer (TRANSDUCER), Amplifier (also known as secondary rod, horn, BOOSTER), welding head (also known as welding, HORN or SONTRODE).

1 Transducer (TRANSDUCER): The function of the transducer is to convert the electrical signal into a mechanical vibration heat riveting machine number. There are two physical effects that can be applied to convert an electrical signal into a mechanical vibration signal. A: Magnetostrictive effect. The magnetostrictive effect is more commonly used in early ultrasonic applications. The advantage is that the power capacity can be made large; the disadvantage is that the conversion efficiency is low, the production is difficult, and it is difficult to mass-produce industrial production. B: The inverse effect of the piezoelectric effect. Piezoelectric ceramic transducers have the advantages of high conversion efficiency, mass production, etc. The disadvantage is that the power capacity produced is small. Existing ultrasonic machines generally use piezoelectric ceramic transducers. Piezoelectric ceramic transducers are made by sandwiching piezoelectric ceramics with two metal front and rear load blocks and tightly connecting them by means of screws. The amplitude of a typical transducer output is about 10 μm.

2 Booming bar (BOOSTER): The booster itself is a metal column. Through the shape design, the amplitude transmitted by the transducer can be amplified into the hot plate machine to achieve the energy amplitude required for processing the plastic part, which is equivalent to heating. The processing temperature required for our commonly used ABS and AS plastics is about 20 μm; the processing amplitude required for nylon and polypropylene is about 50 μm.

3 Welding head (HORN): The function of the welding head is to make for a specific plastic part, in accordance with the shape and processing range of the plastic part.

800W 28Khz Ultrasonic Welding Vibration with Aluminum Booster M8 Screw