Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

40Khz Ultrasonic Replacement Branson Adapter Sleever Converter 4TH

Description:

Replacement BRANSON 40 kHz 4th converter with BNC connector.

Ultrasonic Converters are the core components of many ultrasonic devices such as ultrasonic shearing machines, ultrasonic hot drilling machines, and ultrasonic masking machines. Their main function is to generate ultrasonic waves and convert them into mechanical vibration energy.

Specifications:

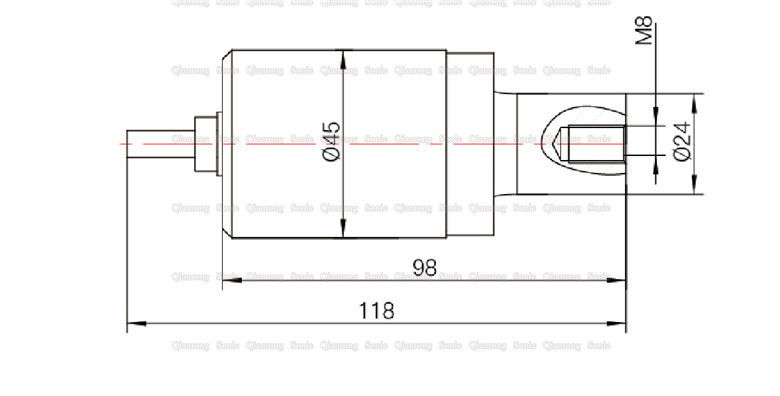

| Model | QR-B4TH |

| Frequency | 40 khz |

| Output power | 800 watt |

| Joint bolt | M8 |

| Ceramic disc Diameter | 25mm |

| Qty of ceramic discs | 4pcs |

| Capacitance | 5.5-6.0nf |

| Amplitude | 4 um |

| Application | Plastic welding machine |

Ultrasonic transducer operating temperature:

Ultrasonic transducers generate heat when used, which is mainly caused by three causes. One is that the material to be heated or ultrasonically treated by the workpiece will heat up, or the mold (tool head) and the horn will heat up for a long time, and this heat will be transferred to the transducer. The second is the power loss of the transducer itself. Since the energy conversion efficiency is not 100%, the energy lost is inevitably converted into heat. The temperature rise will cause the ultrasonic transducer parameters to change, and gradually shift to the best matching state. What is more serious is that the temperature rise will cause the performance of the piezoelectric ceramic wafer to deteriorate. This in turn causes the ultrasonic transducer to work worse and heat up more quickly, which is a vicious circle. Therefore, we must give the ultrasonic transducer a good cooling condition, usually at room temperature and air cooling; if necessary, cold air cooling can also be used. Under normal conditions, the temperature rise caused by these two points is also normal, and under normal cooling conditions, there will be no major problems.

40Khz Ultrasonic Replacement Branson Adapter Sleever Converter 4TH