Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

Flat Solar Colletor 20Khz Ultrasonic Metal Continous Welding Equipment

Description:

The application of ultrasonic metal welding technology has brought about a major improvement in people's quality of life. The professional manufacture of ultrasonic metal welding equipment in Taiwan has introduced this technology into the field of solar energy, leading the overall improvement of industrial equipment manufacturing technology.

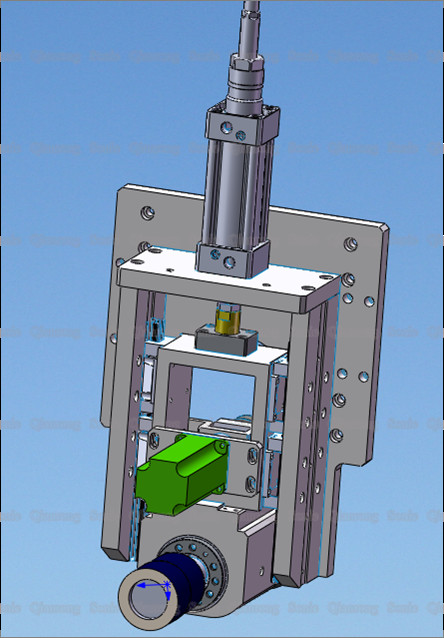

The ultrasonic Rolling welding system is mainly composed of an ultrasonic generator, a transducer, a welding head and a pneumatic part. The system is easy to install, install and operate. All important welding parameters ensure an extremely high weld quality.

Specifications:

| Item No | QR-G2030A |

| Power | 3000W |

| Air Pressure | 0.05-0.9MPa |

| Frequency | 20KHZ |

| Voltage | 380V |

| Dimension of device | Customized |

| Dimension of Generator | 540*380*150mm |

| Working Mode | Continuous |

| Welding Speed | 2-15m/min |

Advantages of ultrasonic metal welding machine:

Comparison between Laser welding and ultrasonic welding:

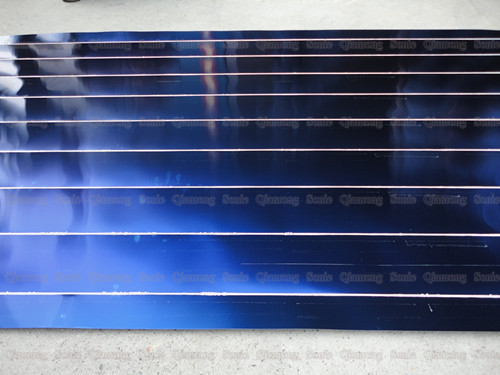

In the solar heat absorbing plate welding, welding is performed in the form of a solder joint with a spacing of 3-5 mm. Laser welding uses a high-energy laser to melt the weld metal to create a joint.

The advantage is that no pressure is required on the workpiece to be welded, the overall deformation is small, and the surface damage of the heat absorption layer is small.

However, the disadvantage is that the absolute heat conduction area between the metal piece and the copper tube is small, which affects the heat conduction efficiency; the copper tube has high flatness requirements and is not easy to be aligned with the welding position; the solder joint strength is poor, and the hot and cold alternates frequently or is subjected to external force. Solder joints are prone to breakage.

In order to further improve the thermal performance, safety and refinement of solar heat absorbing panels,using the automotive and shipbuilding industries as the reference parent, and applies ultrasonic metal technology to solar energy products, greatly improving the welding robustness of the collector. And precision. In terms of heat transfer efficiency, even if ultrasonic welding produces weld marks on the heat absorbing plate, the product of the ultrasonic welding machine is about 3% higher than the heat transfer efficiency of the laser welding (that is, the water temperature is about 3% higher under the same working condition)

Flat Solar Colletor 20Khz Ultrasonic Metal Continous Welding Equipment