Connector Terminal Soldering Metal Weling by 20Khz 4000w Newest

Ultrasonic Technology

Description:

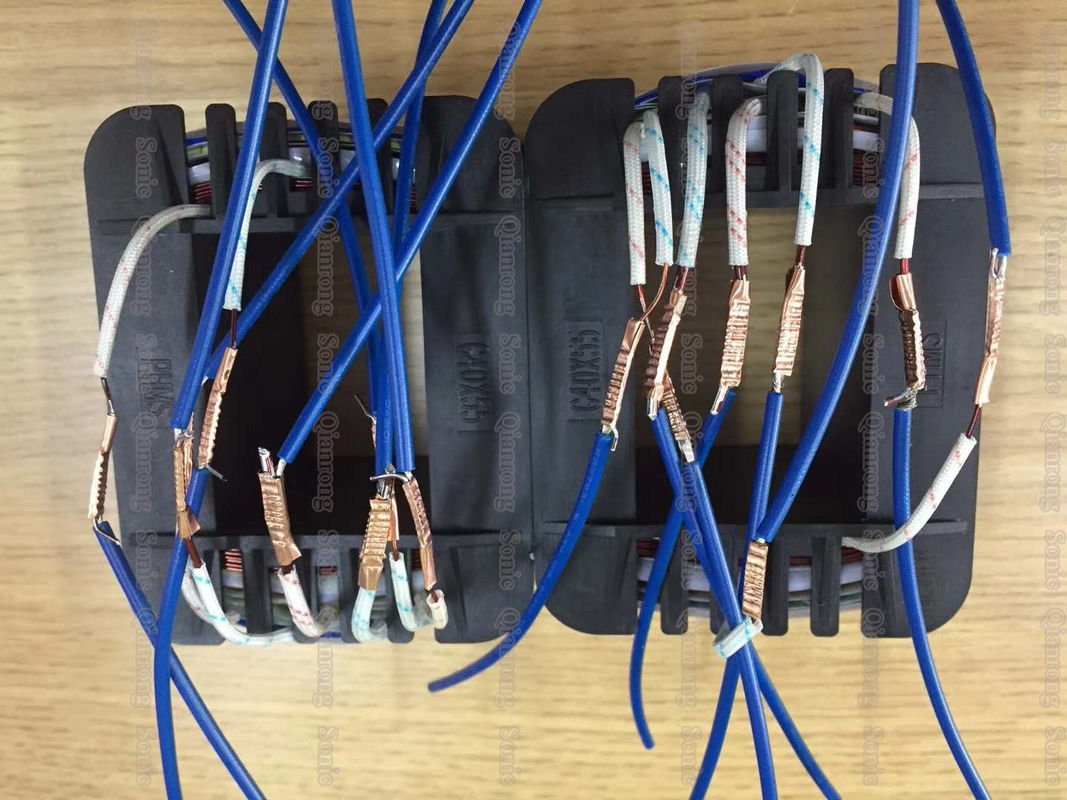

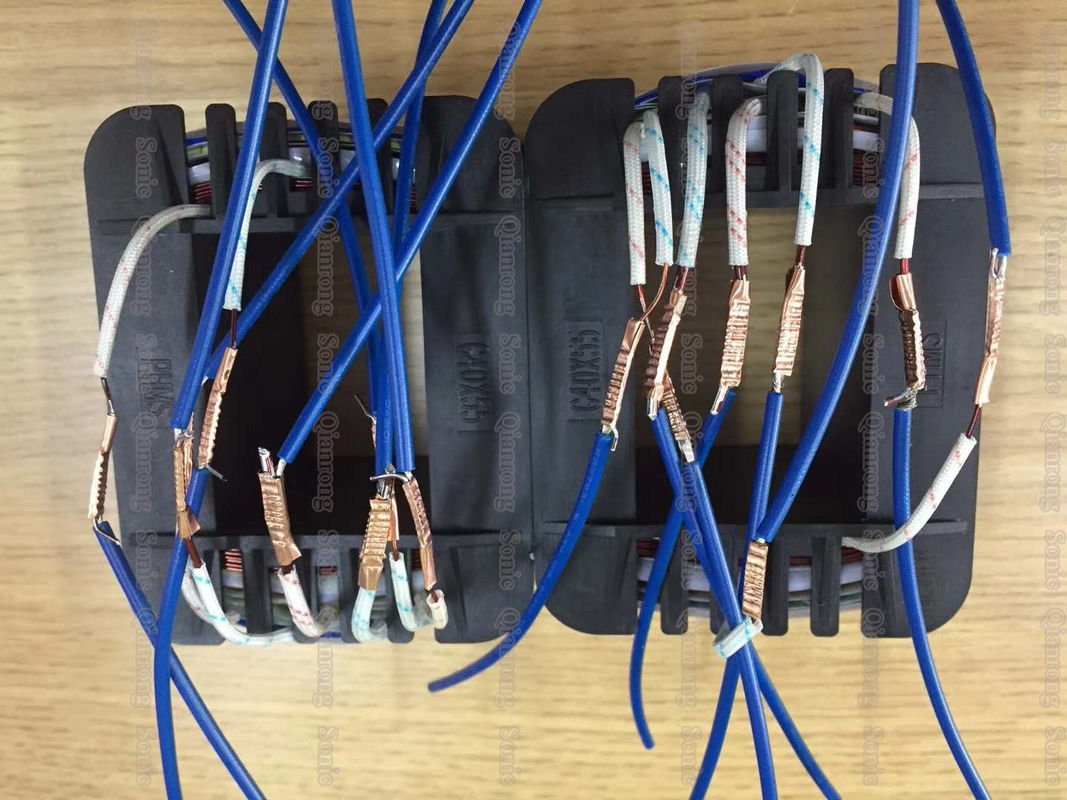

Ultrasonic metal welding can be widely applied to different needs

of car wiring harnesses. Our company has introduced passenger car

copper and aluminum wire harness welding machines and car wire

harnesses and copper terminal welding machines. The machine is a

multi-strand wire crimping welding equipment, which can reliably

and quickly weld a plurality of copper wire bundles and aluminum

wire bundles with a cross-sectional area of 0.5-30 mm. The car wire

harness welding machine uses the ultrasonic metal welding skill to

perform the parallel welding of the copper exposure wire. The

ultrasonic welding process is a mechanical process, no current

flows through the workpiece, and no melting occurs. Its electrical

and thermal functions are not available in other processes.

Compared with fusion welding, ultrasonic welding has low cost, long

life and low labor intensity.

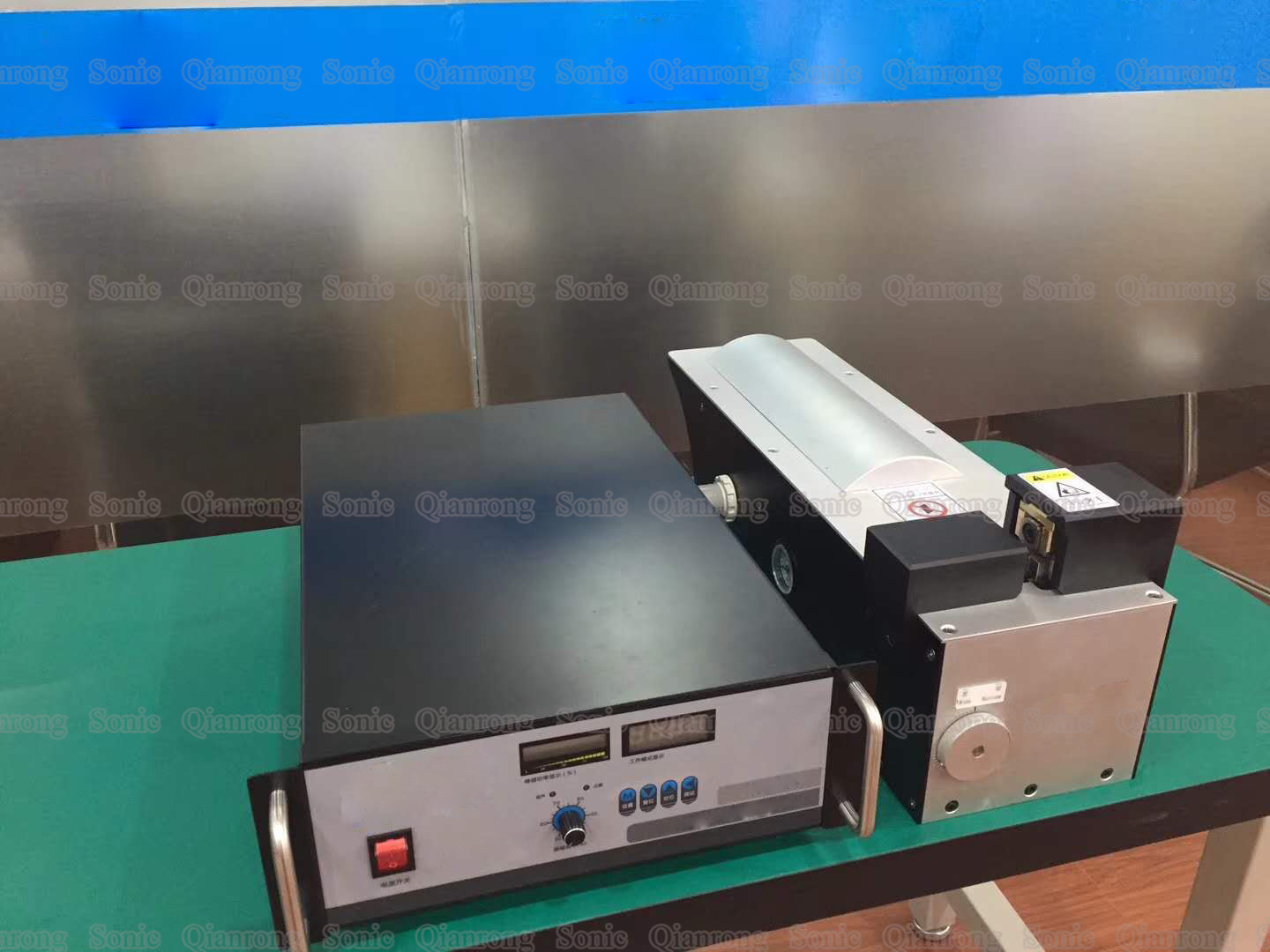

Parameters:

| Item No | QR-X2020A | QR-X2030A | QR-X2040A |

| Power | 2000W | 3000W | 4000W |

| Welding Area | 0.5-16mm2 | 0.5-20mm2 | 1-30mm2 |

| Air Pressure | 0.05-0.9MPa | 0.05-0.9MPa | 0.05-0.9MPa |

| Frequency | 20KHZ | 20KHZ | 20KHZ |

| Voltage | 220V | 220V | 220V |

| Weight of horn | 18KG | 22KG | 28KG |

| Dimension of Horn | 530*210*230mm | 550*220*240mm | 550*250*240mm |

| Generator Size | 540*380*150mm | 540*380*150mm | 540*380*150mm |

Features:

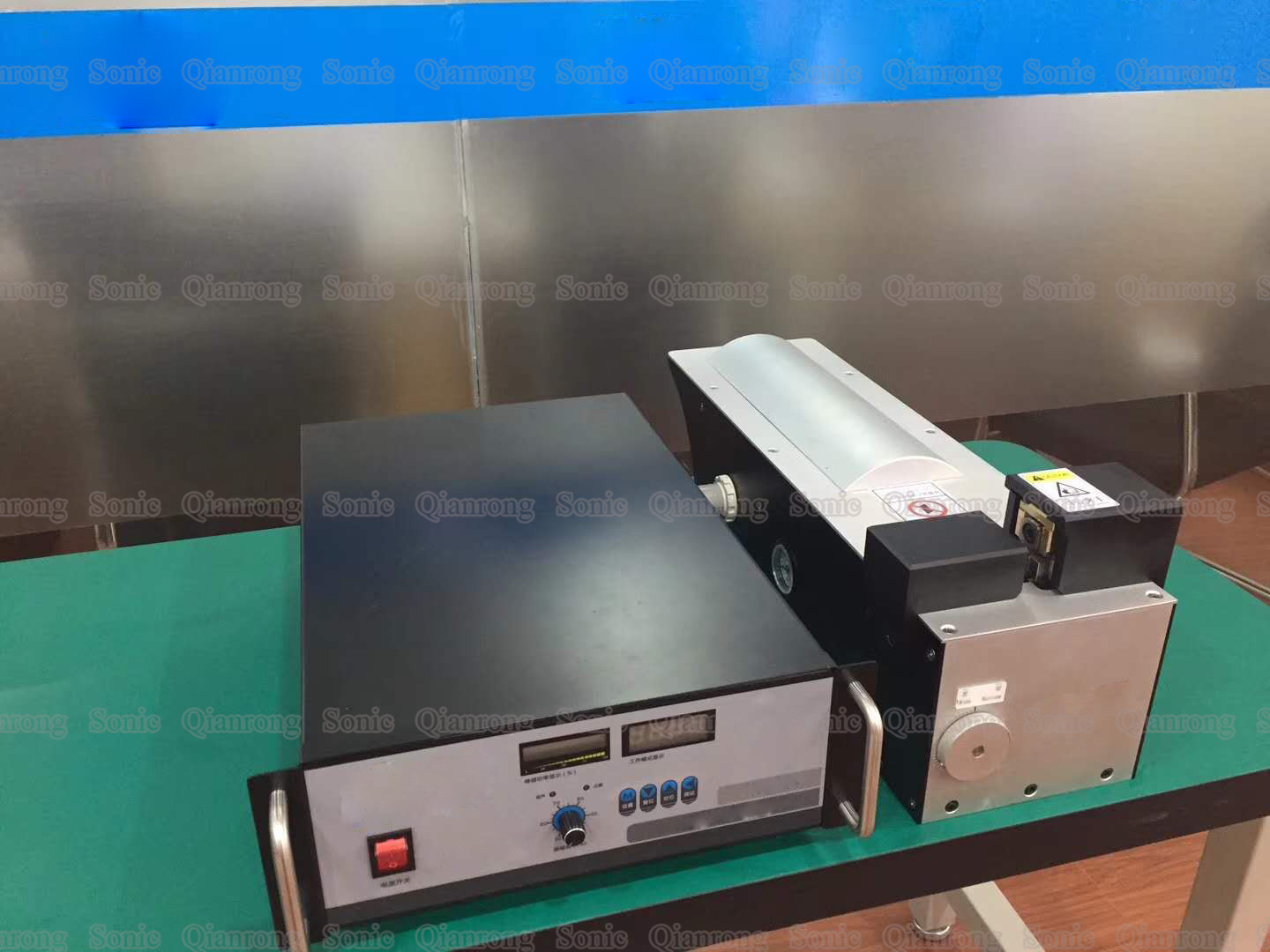

1. Ultrasonic multi-strand copper alloy wire welding machine is

compact in design, light in weight and easy to move;

2, copper alloy wire harness special welding machine compared with

other pressure welding, the pressure is required to be small, and

the deformation amount is less than 10%, and the workpiece

deformation of cold pressure welding is 40%-90%;

3. Ultrasonic motor copper alloy wire welding machine combines

quality control system for automatic process monitoring;

4. The overall design of the welding head of the electric vehicle

copper alloy wire harness welding machine can ensure the

consistency of the welding effect and extend the life of the

welding head;

5, ultrasonic copper alloy wire welding machine uses Japanese and

American brand parts, the quality is guaranteed;

6. Ultrasonic copper alloy wire spot welding machine adopts PLC

control, with man-machine interface as operation terminal,

convenient and reliable operation mode, and intuitive operation

state monitoring function.

Application:

Ultrasonic copper copper wire harness welding machine is suitable

for single, multi-point, square, strip, single layer, multi-layer,

composite welding of aluminum, nickel, copper, silver and other

thin and thin materials, especially metal foil, thin metal ,

encrypted welding of thin wires. Such as: automotive terminal

blocks, copper braided wire, multilayer aluminum sheet, automotive

wiring harness, motor terminal, thermocouple, thyristor component,

refrigerator electrolysis, capacitor pole piece, carbon brush

piece, heat sink frame, copper tube, copper tube + Aluminum sheet,

copper tube + copper sheet, braided copper wire type, airbag,

capacitor leads to Ruizi, electrical switch silver contact, motor

terminal, engine terminal, electrical connector, electronic

components, terminals and cables, Rotor rectifier, motor coil, etc.

Involved in hardware, batteries, electronics, automotive,

electrical, electrical, solar, machinery and other industries.

Connector Terminal Soldering Metal Weling by 20Khz 4000w Newest

Ultrasonic Technology