Tianjin Ruiyuan Electric Material Co,.Ltd |

|

Verified Suppliers

|

|

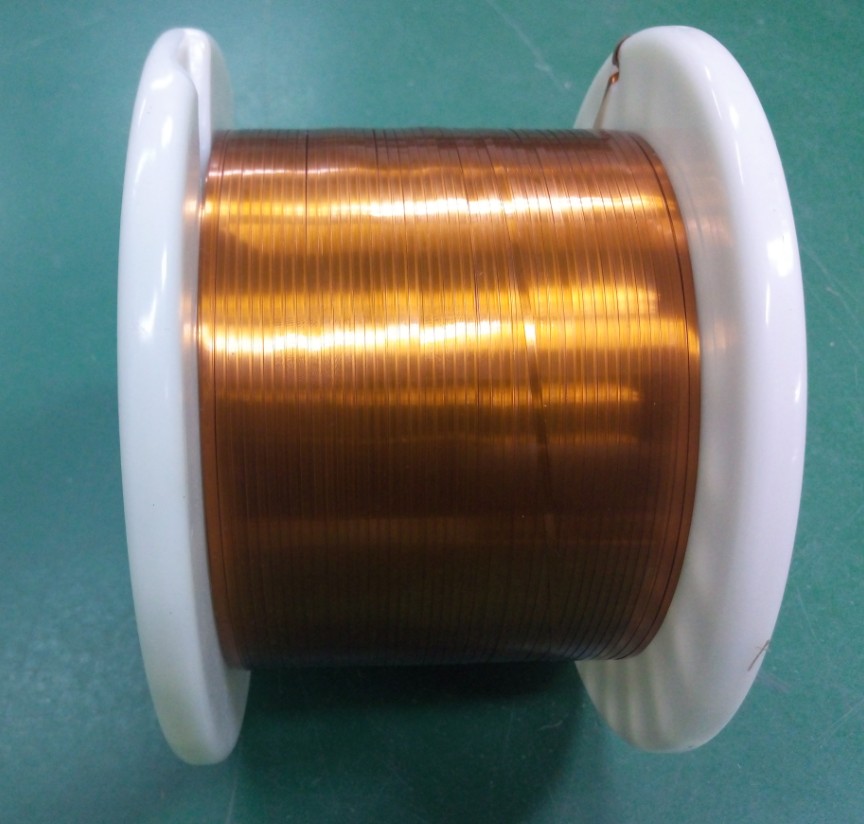

0.02 - 1.8MM FLAT RECTANGULAR ENAMELED COPPER WIRE SELF BONDIGN WIRE IEC CERTIFICATION

Today most popular Notebook computers, PDA...and many other 3C products, are ever-possible designing to make its shape and structure become as light, thin, short and small as possible; while this development demanding the stricter characteristics of its coil, also resulting the conventional enamelled copper wire unfitted for the trend. This special demand for smaller-dimension and higher-efficiency makes the fiat-shape coil become the mainstream of the future, in response to this brand new trend, the Company successfully developed the "Enamelled Flat Copper Wire" for the market

FEATURES AND BENEFITS

The enamelled flat copper wire can form a bigger cross-sectional coil area than an enamelled round copper wire in the same winding space, so the coil can obtain a lower electrical resistance to prevent appliance overheat and more suitable for high-current loading with the current up to 40A above.

The enamelled flat copper wire can form a bigger surface area of the coil than an enamelled round copper wire under the same conductor resistance (meaning the same cross-sectional area), makes it significantly mitigate the skin effect with some high frequency transmission up to 100 KHz.

The enamelled flat copper wire can create a comparative higher space factor, as well as a lower volume-occupation, presenting its advantageous as a lighter, thinner, shorter and smaller product.

APPLICATION

Notebook coil.

Coils of printer.

Motors of CD driver.

Transformer.

Speaker

Nominal Diameter mm | Tolerance | Min. Increase of Diameter | Max. Overall Diameter | Breakdown Voltage |

| Elongation | Pin Hole | Electrical Resistance |

|

| mm |

|

| ≥ V |

| ≥% | ≤Default/5m | Ω/km (20℃) |

|

|

|

|

| Mandrel Method | Twisted Method |

|

| Min. | Max. |

0.012 | ---- | 0.013 | 0.015 | 50 | ---- | 5 | 10 | 142.64 | 157.65 |

0.013 | ---- | 0.015 | 0.017 | 70 | ---- | 5 | 10 | 118.41 | 133.98 |

0.014 | ---- | 0.016 | 0.018 | 70 | ---- | 5 | 10 | 102.64 | 120.45 |

0.015 | ---- | 0.017 | 0.02 | 80 | ---- | 5 | 10 | 89.83 | 104.41 |

0.016 | ---- | 0.018 | 0.021 | 90 | ---- | 5 | 8 | 74.67 | 97.56 |

0.017 | ---- | 0.019 | 0.022 | 90 | ---- | 5 | 8 | 66.6 | 85.75 |

0.018 | ---- | 0.02 | 0.023 | 100 | ---- | 5 | 8 | 59.77 | 75.95 |

0.019 | ---- | 0.021 | 0.024 | 100 | ---- | 5 | 8 | 53.95 | 67.75 |

0.02 | 0.001 | 0.022 | 0.024 | 100 | ---- | 8 | 8 | 51.83 | 60.81 |

0.05 | ±0.002 | 0.007 | 0.062 | 400 | 1200 | 12 | 5 | 7981 | 9528 |

0.055 | ±0.002 | 0.007 | 0.068 | 400 | 1200 | 12 | 5 | 6642 | 7815 |

0.06 | ±0.002 | 0.007 | 0.073 | 500 | 1200 | 14 | 5 | 5614 | 6526 |

0.065 | ±0.002 | 0.007 | 0.078 | 500 | 1200 | 14 | 5 | 4807 | 5531 |

0.07 | ±0.002 | 0.007 | 0.083 | 500 | 1200 | 15 | 5 | 4163 | 4747 |

0.075 | ±0.002 | 0.007 | 0.088 | 550 | 1200 | 15 | 5 | 3640 | 4119 |

0.08 | ±0.002 | 0.008 | 0.094 | 550 | 1200 | 16 | 5 | 3209 | 3608 |

0.085 | ±0.002 | 0.008 | 0.099 | 550 | 1200 | 16 | 5 | 2851 | 3187 |

0.09 | ±0.002 | 0.01 | 0.106 | 650 | 1200 | 16 | 5 | 2550 | 2835 |

0.095 | ±0.002 | 0.01 | 0.111 | 650 | 1200 | 17 | 5 | 2294 | 2538 |

0.1 | ±0.002 | 0.011 | 0.118 | 650 | 1200 | 17 | 5 | 2074 | 2286 |

0.11 | ±0.002 | 0.011 | 0.129 | ---- | 1300 | 17 | 5 | 1720 | 1882 |

0.12 | ±0.002 | 0.011 | 0.139 | ---- | 1500 | 17 | 5 | 1450 | 1577 |

0.13 | ±0.002 | 0.011 | 0.149 | ---- | 1500 | 18 | 5 | 1239 | 1340 |

0.14 | ±0.002 | 0.011 | 0.159 | ---- | 1600 | 19 | 5 | 1070 | 1153 |

0.15 | ±0.002 | 0.011 | 0.169 | ---- | 1700 | 20 | 5 | 934.1 | 1002 |

0.16 | ±0.002 | 0.012 | 0.18 | ---- | 1700 | 21 | 5 | 822.3 | 879.4 |

0.17 | ±0.003 | 0.013 | 0.192 | ---- | 2000 | 22 | 5 | 721.1 | 787.1 |

0.18 | ±0.003 | 0.014 | 0.204 | ---- | 2000 | 22 | 5 | 644.4 | 700.7 |

0.19 | ±0.003 | 0.014 | 0.214 | ---- | 2000 | 23 | 5 | 579.4 | 627.8 |

0.2 | ±0.003 | 0.014 | 0.224 | ---- | 2000 | 23 | 5 | 523.7 | 565.7 |