Guangdong Uchi Electronics Co.,Ltd |

|

Verified Suppliers

|

|

Silver Electrode NTC Thermistor Chip MF58 100KOhm 3950 For Infrared Forehead Thermometer Thermopile Sensor

1. Application

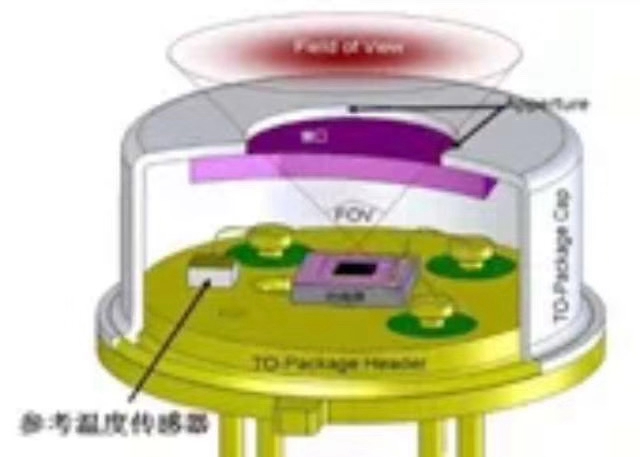

Infrared Forehead Thermometer Thermopile Sensor

Main part number :

NISAILA H-TPSF5.5,AMPHENOL ZTP-148SR,OMRON D6T-1A-02,EXCELITAS TPS334L5.5 ST32-HT2.1A1,MELEXIS MLX90247,HLPLANAR TS118,HEIMANN HMSJ11 F5.5,TE CONNECTIVITY TSEV01S01C05 TS418-IN426,MEAS TS318-5C50,SEMITEC 10TP593T,SENBA ISB-TS45H,MRT117,SMARTEC SMTIR9901/02,OTP-628D2,ZGF55,PERKINELMER TPMS334L5.5,MTP10-B1F55,STP9CF55,TEXAS INSTRUMENTS TMP007/TMP006YZF,GE ZTP101T,ALPHASENSE,IDT etc.

2. Part Numbering

MF 58 chip 1 0 4 H 3 9 5 0 A A B M

①

② ③ ④

⑤ ⑥ ⑦

⑧

① Type :MF58 NTC thermistor chip

② R25: 10× 104Ω

③ Tolerance(%): ±3%

④ B value: 3950K

⑤ Measuring Temp.: 25/50℃

⑥ Electrode material: Silver electrode

⑦ Welding method:Binding

⑧ Package:Blue film

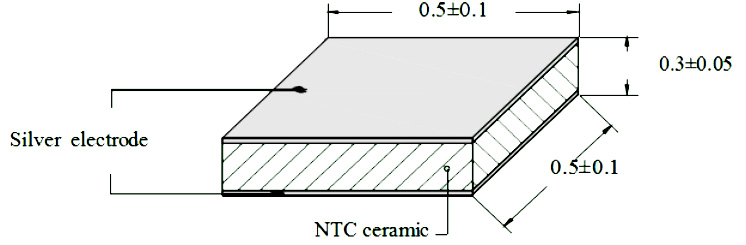

3. Size (mm)

4. Electricity

| NO. | Item | Code | Test Conditions | Range | Unit |

| 1 | Resistance at 25 ℃ | R25 | T=25±0.01℃ | 100±3% | KΩ |

| 2 | B value | B25/50 | 3950±1% | K | |

| 3 | Thermal time constant | τ | 50℃→25℃, in oil | ≤1.0 | Sec |

| 4 | Dissipation coefficient | δ | Ta=25±0.5℃ | ~0.2 | mW/℃ |

| 5 | Max rated power | Pmax | Ta=25±0.5℃ | ≤10 | mW |

| 6 | Operating temp | / | / | -40~+125 | ℃ |

a. Resistance (R25)

Requirements:R25=100KΩ±3%

Test method: It is measured in a high precision oil tank with

constant temperature of

25℃±0.01℃ and applies a high-precision resistance measuring

instrument. The instrument’s

measuring power should be zero power.(In other words, the chip

self-heating generated by the

current flowing through the product is negligible)

b.B value

Requirements:B25/50=3950K±1%

Test method:Measure resistance in a high precision oil tank with

constant temperature of

25℃±0.01℃ and 50±0.01℃. Then calculate B value according to the

following

formula:Bt1/t2=ln(Rt1/Rt2)/(1/(T1+273.15)-1/(T2+273.15)).

c.Thermal time constant(τ)

Requirements:T1=50-(50-25)*63.2%=34.2℃, τmax = 1.0 S (in oil).

Test method:Calculate the time required for the product's

resistance at 50℃ rapidly converted to

corresponding resistance at 34.2℃ in the oil tank.

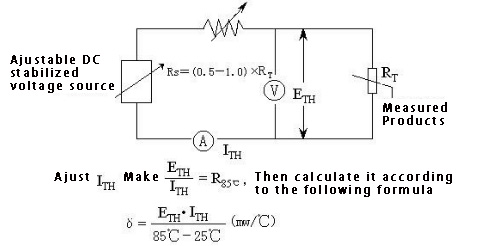

d.Dissipation coefficient(δ)

Test method : (The product under test is connected to the following

circuit in still air at

25±0.5℃ )

e.Max rated power(Pmax) Rated power:Ta=25±0.5℃, Pmax=10mW.

f.Max rated power(Pmax) Rated power:Ta=25±0.5℃, Pmax=10mW.

5.Certificates

5.1 Quality Management System:ISO9001:2015 IATF16949:2016

5.2 Environment Management System:ISO14001:2015

5.3 Intellectual Property Management System:GB/T29490-2013

5.4 Integrated Information Technology and Industrialization

Management System:AITTRE-00920111MS0088301

5.5 CQC:CQC09001033986

5.6 SafetyApproval:UL, C-UL:E240991

5.710,000 durability test ofUL

5.8 AEC-Q200:20172052558G

5.9 Environmental test report:RoHS

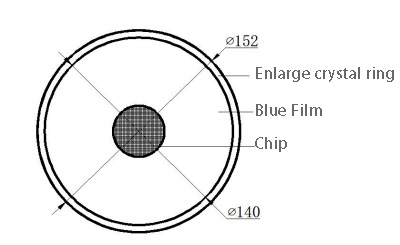

6.Packaging

6.1 Blue film packaging

The blue film was put into the wafer expanding machine and smoothly

inlaid on the wafer expanding

ring, and then the NTC chips was tidily arranged on the blue film

by the sticking membrane.

Quantity of each layer: about 2.5KPcs/Disk, center distance ≈0.6mm.

6.2 Packed in paper box, each box has 10 layers, 3 boxes for small

carton and 6 boxes for large carton.

7.Mode of transport and storage

7.1 In the process of storage and transportation, the height of

each stack shall not exceed 4 boxes, and the chip must be

stored in vacuum and anti-oxidation packaging.

7.2 Select the packing box according to the shipment quantity, any

method of transportation is allowed;However,it is necessary to

avoid contamination, the direct or indirect pouring of rain or snow

and mechanical damages during transportation.

7.3 Products shall be stored in an environment free from acidic or

alkaline substances, corrosive gases or radiation sources, and

shall be avoided in an environment with light.

7.4 Storage temperature: -10℃~ +40℃.

7.5 Relative humidity: ≤55%RH.

7.6 Stored in an inert gas.

8.Storage life

8.1 Under the guarantee of complete sealing package and the above

storage conditions, the chips in bulk can be kept for 1 year

in vacuum sealing package, and the chips with blue film can be kept

for 6 months in the vacuum sealing package, otherwise the chip

electrode will oxidize.(Storage in an inert gas

is recommended)

8.2 After opening the film, please use the product within 24 hours

under normal temperature and normal humidity indoor. If not,

please keep the product according to the storage method.

8.43 The shelf life of the packaging material (blue film) is 3

months, the viscosity of the blue film is easy to increase for

a long-time storage, leading to difficulties in wafer taking and

adhesion.

9.Service life

The service life of this thermistor chip is 10 years, subject to

the conditions of this approval sheet.

10.Description

In the process of preventing and controlling the new coronavirus epidemic, medical products such as ventilators, monitors, oxygen generators, negative pressure ambulances, and forehead guns have played a significant role. The non-contact temperature measurement method of the forehead gun can avoid contact cross infection and play a convenient and quick role in preventing and controlling the epidemic of the general public.

Forehead guns and ear thermometers use thermopile probe infrared

thermometers to measure the radiant energy emitted by an object.

According to Boltzmann's law (E = σεTⁿ), the greater the radiant

energy, the higher the temperature After transforming the infrared

radiation signal into an electrical signal, it can be finally

converted into the temperature value of the measured target after

being corrected by an amplifier and a signal processing circuit and

corrected according to a certain algorithm and target emissivity.

The main device for temperature measurement is the thermopile. A

thermopile infrared probe is a temperature sensor consisting of a

series of thermocouples connected in series. The two ends of a

thermocouple are composed of two different materials. When one end

contacts the hot end and the other end contacts the cold end, a

potential difference will occur between the two different materials

due to the see-beck effect. The magnitude of the potential

difference is between the two different materials. The temperature

difference is related. A thermopile sensor connects a series of

thermocouples in series to increase the detection sensitivity of

the sensor.

In order to be able to calculate correctly at different ambient

temperatures, a high-precision NTC thermistor is used to measure

the ambient temperature of the thermopile. According to some

standard temperature conditions written in advance, for example:

the temperature of the measured object is 37 ° C, The output

temperature of the thermopile is 25 ℃, and the measured temperature

is calculated by the output voltage of the thermopile and the

absolute temperature of the environment of the thermopile. MF58

temperature-measuring NTC thermistor 100KΩ3950 is a commonly used

specification. There are also use schemes in which chips of this

type are directly used and combined with thermopile using a bonding

packaging process.

Our MF58 temperature-measuring NTC thermistor series products have

good stability and high reliability; a wide range of resistance

values and high precision; small size, light weight, rugged

structure, and convenient for automatic installation; fast thermal

induction, sensitivity Higher characteristics. MF58 products are

widely used in home appliances, office automation equipment

temperature detection or temperature compensation, mobile phone

batteries, battery packs, instrument coils, integrated circuits,

quartz crystal oscillations and thermocouples / thermopiles. The

MF58 product produced by UCHI has obtained CQC mark certification,

UL, C-UL safety certification, passed the most severe 100,000

durability tests in the UL standard, and passed AEC-Q200 testing,

which is unique in China. Reliable performance and superior quality

can be trusted.