Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Model400 Corrosion Resistance Extruder Screw Segments for Petrochemical Industry

| Screw Design | Double-Screw |

| Hardness | 58-60HRC |

| Heat treatment | Vaccum heat treatment |

| Surface Treatment | Polishing |

| Feature | Single keylot |

| Standard | DIN, GB, etc. |

| Technicals | CNC machining |

4. Our strength

They finish machining is carried out before heat treatment, and after heat treatment, the shape of the products are uncontrolled, so they cannot control precision. Our finishing is done after heat treatment, and can eliminate deformation of the parts in the heat treatment, then the precision of gear precision can reach level 6, achieving seamless connection.

5. Equipment

Joiner is state-of-the art and spans over 20,000 square meters. The factory houses more than 140 sets of different domestic and foreign high precision production equipment, with the degree of numerical control up to 95%.

6. Raw material guarantee

The company has been cooperating with domestic and foreign first-line brand material suppliers for a long time, and has a strict quality control and performs regular audits and inspection of the factory (elemental analysis, metallographic analysis, ultrasonic flaw detection, etc.) to ensure a 100% qualified status.

7. Packing Details:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

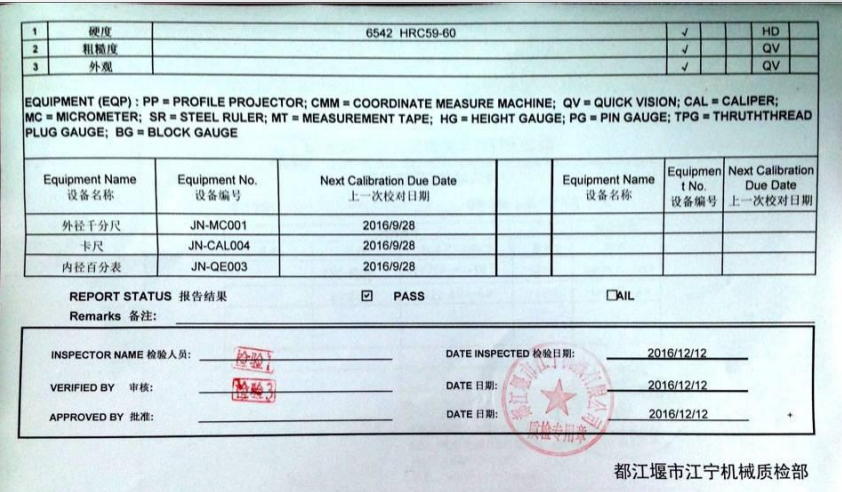

8. Testing Reports

We will send Inspection reports for every customer.

a. General Dimension Inspection Report

b. Material certificate.

9. Why choose us?

(1) Total solution of highly wear-resistance and

corrosion-resistance problems;

(2) Expert of engineering design and consulting,

(3) Advanced manufacturing capabilities and technology,

(4) Lean production management.

(5) Top quality products with high cost performance.

10. Products photos