Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

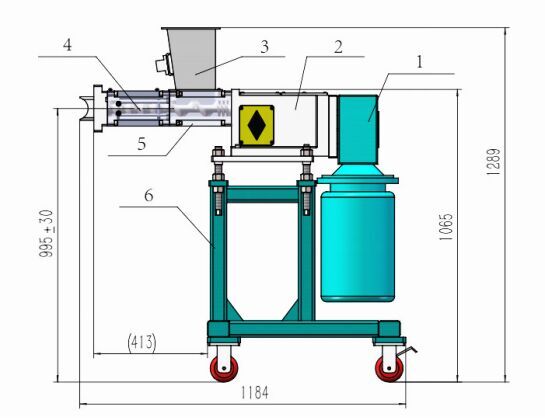

CWJ45 Side feeder for plastic and rubber twin screw extruder machinery parts

CWJ45 Technical Specification

| Screw Diameter(mm) | Φ45.5mm |  |

| L/D | 10: 1 | |

| Power(kw) | 3KW | |

| Type of drive | SEW Motor | |

| Sections of Barrel | 2 Sections | |

| Length of Screw | 450 mm | |

| Output Screw Speed(rpm) | 300 rpm | |

| Load Capacity (kg/h) | 100 kg/h | Dimension: 1300×650×1230(mm) (can adjustable height) |

The composents of CWJ45 Side Feeder

| Mark | Part Name | Qty(Pcs) | Function |  |

| 1 | SEW Motor | 1 | Driving System | |

| 2 | Gear Box | 1 | Transmission System | |

| 3 | Hopper | 1 | Feeding | |

| 4 | Screw Section | 2 | Mixing and Conveying the filler | |

| 5 | Barrel Section | 2 | Carry the screw shaft and melt the material | |

| 6 | Bracket | 2 | Supporting the side feeder |

Basic information about our products

JOINER employs segmented screws with a selfwiping profile to provide poptimum feeding properties

for a wide range of raw materials such as fillers,fiberglass,

talcum powder,calcium carbonate and carbonate and most inorganic

materials.

Side feeders are used for the following reasons

1. Reduction of wear costs in the melting section of

the main screw and barrels

2· More gentle processing of fillers

3· Increase in throughput

4· Increase in quality through the enough fixing

5· Lower the cost

Our side feeders features

1· Very durable thanks to its durable integral liner inside

barrels

2· The tightly intermeshing co-rotating segments with various

pitch have an improved conveying be haviour and ensure the

precision (long GF±5%,short GF±2%) and output (caco3

550Kg/h,GF 500Kg/h)

3· More human centered design,ease of operation.for example

the glass window,on the splined sleeve, flat screw head ,the

adjustable support and the drawer for clean up the leak .Can

designed based on user requests.

All Joiner Screw elements are manufactured using only top quality wear and corrosion

resistant steels.

Tooling steel,Nitriding, stainless steels and alloys or specially

imported treated materials are all available

depending on the customers specific requirements.

Side Feeder for

| W&P: ZSK-MC | Berstorff: ZE |

| Leistritz:ZSE -MICRO | Theysohn: TSK |

| Maris: TM-W | APV: MP65 |

| JSW: TEX | Feddem: FED-MTS |

| Fessia Macross: NRII | TOSHIBA: TEM |

| Labtech: LTE | USEON:TDS |

| SHIZHOU: MTE | KEYA, LANTAI |

Packing and Delivery

Packing Details: Standard packing for Joiner Extruder twin screw extruder

parts/extruder spare parts

Delivery Details: Standard export packing

Delivery Time: Shipped in 45 days after payment for Side Feeder.

FAQ

1. Q: Are you a factory or trading company?

----A: A factory

2. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Chengdu, Sichuan Province, China,

1) You can fly to Chengdu Airport directly. We will pick you up

when you arrive in the airport;

All our clients, from domestic or abroad, are warmly welcome to

visit us!

3.Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even

within the hour.

If you need an advice, just call our export office at +86

17828480939, we will answer your questions immediately.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working

days.

As a manufacturer, we can ensure the delivery time according to the

formal contract.

4.Q: How about the delivery time?

----A: This depends on the product. Typically standard products are

delivered within 30 days.

5.Q: May I know the status of my order?

----A: Yes .We will send you information and photos at different

production stage of your order. You will get the latest information

in time.

Contact Information

Ms Jessica Zhang

Email:86 18380438354

What'sup: +86 18380438354

Mail: jessica.zhang@jiangningjx.com