Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

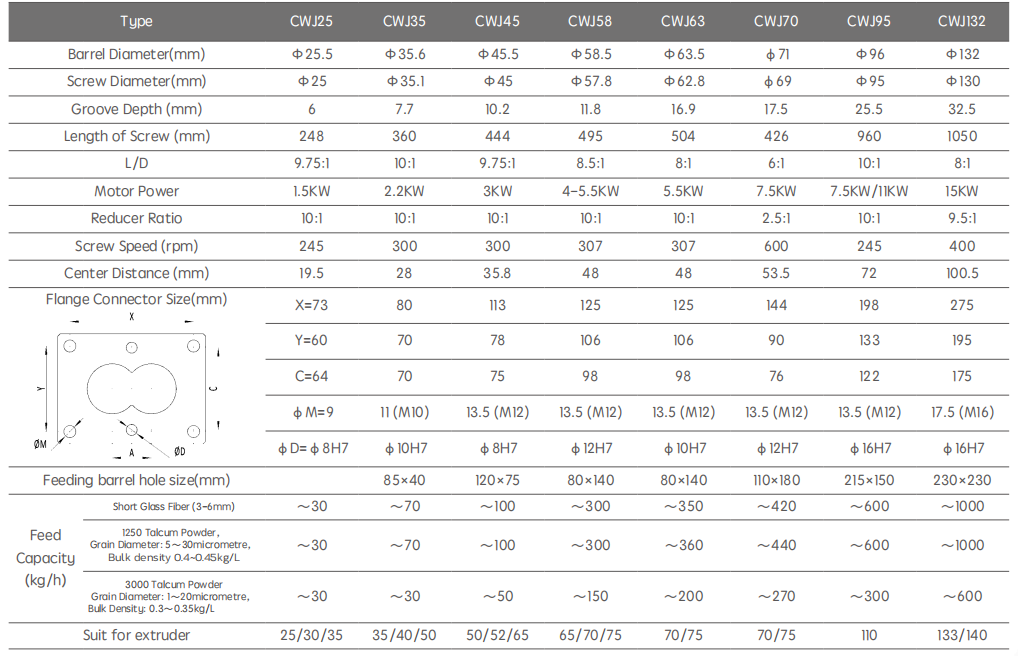

4KW/5.5KW Side Feeder Feeding Short Glass Fiber And Talcum Powder For Twin Screw Extruder

1. About Joiner side feeder

Joiner employs segmented screws with a self-wiping profile to provide optimum feeding properties for a wide range of raw materials such as fillers, fiberglass, talcum powder, calcium carbonate and most inorganic materials.

| Mark | Part Name | Qty (Pcs) | Function |

| 1 | SEW Motor | 1 | Driving System |

| 2 | Gearbox Section | 1 | Transmission System |

| 3 | Hopper | 1 | Feeding |

| 4 | Screw Section | 2 | Mixing and conveying the filler |

| 5 | Barrel Section | 2 | Carry the screw shaft and melt the material |

| 6 | Bracket | 2 | Supporting the Side Feeder |

2. Flange connectors are used to connect with the main extruder.

X=125mm

Y=106mm

C=64mm

M=13.5mm

3. Advantages of Joiner Extrusion Side Feeder

1). Independently develop and produce gearboxes.

a. All gearboxes are machined by gear grinding, the accuracy is up to six grades, and carburizing and hardening the tooth surface, thus ensuring that the noise of gearboxes is very low.

b. Gear casting is made of resin sand and machining center to ensure high precision.

c. The gearbox’s bearing is imported from Germany.

d. The gearbox has unique design, long life and low noise.

e. The gearbox and screw element are connected by spline sleeve, which is very convenient to disassemble

2). Barrel is made of wear resistant alloy steel and cooled by water channel.

3). Screw adopts modular screw, and the screw assembly can be adjusted according to different feeding materials to meet different feeding requirements.

4. Side feeders are used for the following reasons:

-- reduction of wear costs in the melting section of the main screw and barrels

-- More gentle processing of fillers

-- Increase in throughput

-- Increase in quality through the enough fixing

-- Lower the cost

5. Other types of side feeders

6. Service Network Assurance

We have a professional sales team who can quickly understand the real needs of customers, and put forward reasonable solutions for them. The company not only offers supportive services for both domestic and foreign brands, but also provides retail services to outstanding end customers in the industry. Now Joiner products are exported to more than 30 countries including countries such as Europe and America.

7. Packing:

We use wooden boxes to pack the machines. All of them are customized according to the size of the machine, which can effectively prevent transportation damage, and protect the products.

8. FAQ

1. Q: Are you a factory or trading company?

----A: A factory

2. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Chengdu, Sichuan Province, China,

You can fly to Chengdu Airport directly. We will pick you up when you arrive in the airport. All our clients, from domestic or abroad, are warmly welcome to visit us!

3. Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us.

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86-28-87226313, we will answer your questions immediately.

2) Our quick manufacturing time

As a manufacturer, we can ensure the delivery time according to the formal contract.

4. Q: May I know the status of my order?

----A: Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time.

Contact Joiner for more: jessica.zhang@jiangningjx.com