Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

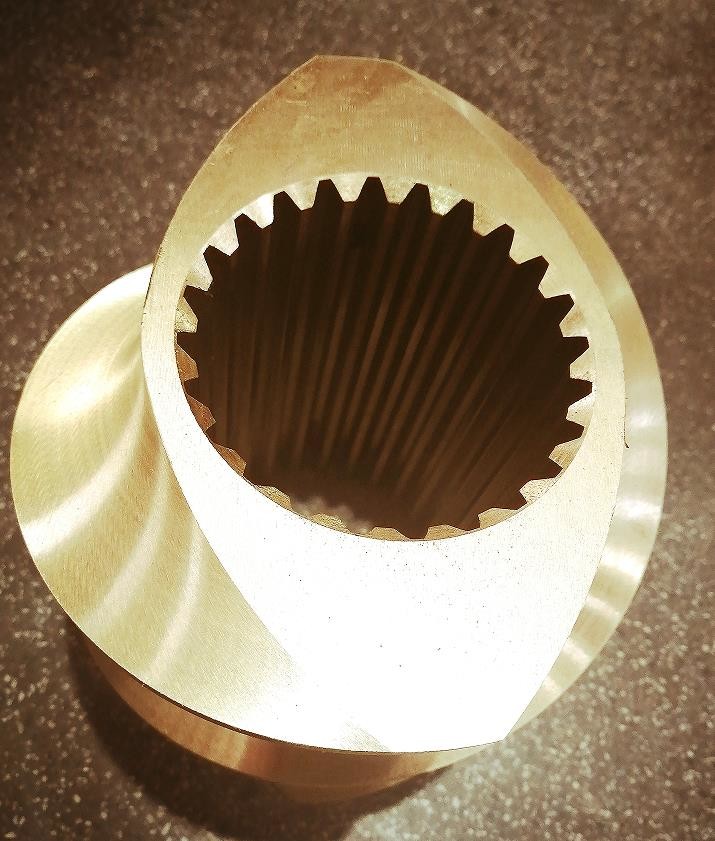

Polishing Aluminium Bronze Extruder Screw Elements 2 Flighted For Puffed Food Industry

Screw elements are the main working parts for twin screw extruder which determined the quality and output of plastic products. With high quality, the screw elements assure plastic molecular mixing, cutting, spreading as well as reacting among themselves etc. Extremely high self cleaning performance assure the high quality of the whole production line, for this, our company combiend our experience for years, the merits about foreign countries and the customer's use,then take them into action, design and produce all kinds of suitable processing screw elements.

| Screw Design | Double-Screw |  |

| Hardness | 58-60HRC | |

| Brand Name | JOINER | |

| Surface Treatment | Polishing | |

| Materials | Aluminium-Bronze | |

| Place of Origin | Sichuan, China | |

| Screw length | L=146mm | |

| Screw diameter | Φ 146mm |

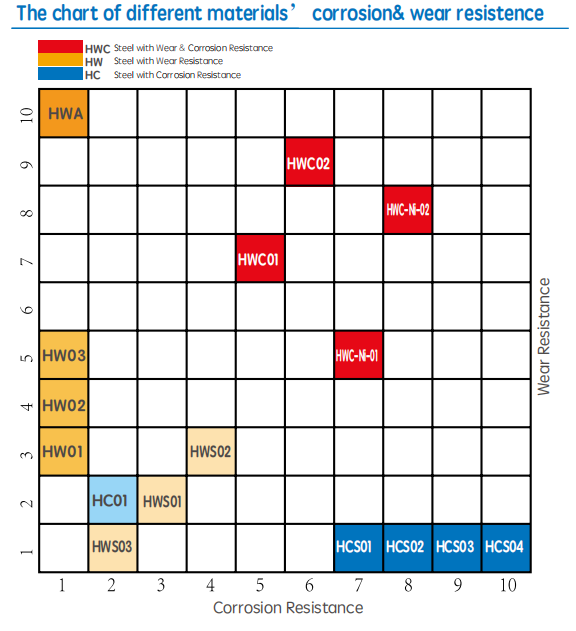

2. Other Optional Screw Elements Materials

3. Series Extruder Screw Elements

| Special Screw Segment | Convey Screw Element |

| Mixing Screw Element | Kneading Block and disk |

| Transition Screw Element | Screw Element for Side Feeder |

| Screw Element for Side Feeder |

4. Making process

5. Heat treatment

As we all know, heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves. In China, we are the only company that does heat treatment by ourselves, and the heat treatment of screw components made by Nanjing factory is processed by outsiders, so the quality of products can not be completely guarantee.

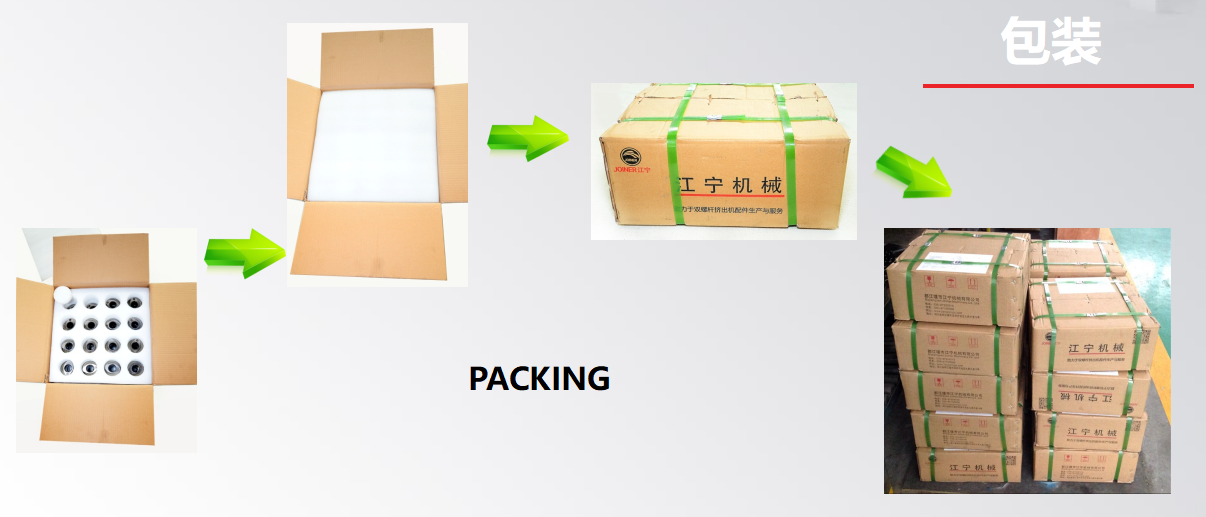

6. Extruder Screw Elements Packing

At first: antirust processing ,

Then using paper packages,bubblestopack;

Next, fixing them in the wooden cases.

7. Extruder Screw Elements Testing Reports

We will send Inspection reports for every our

customer.

1). General Dimension Inspection Report

2). Material certificate for customer.

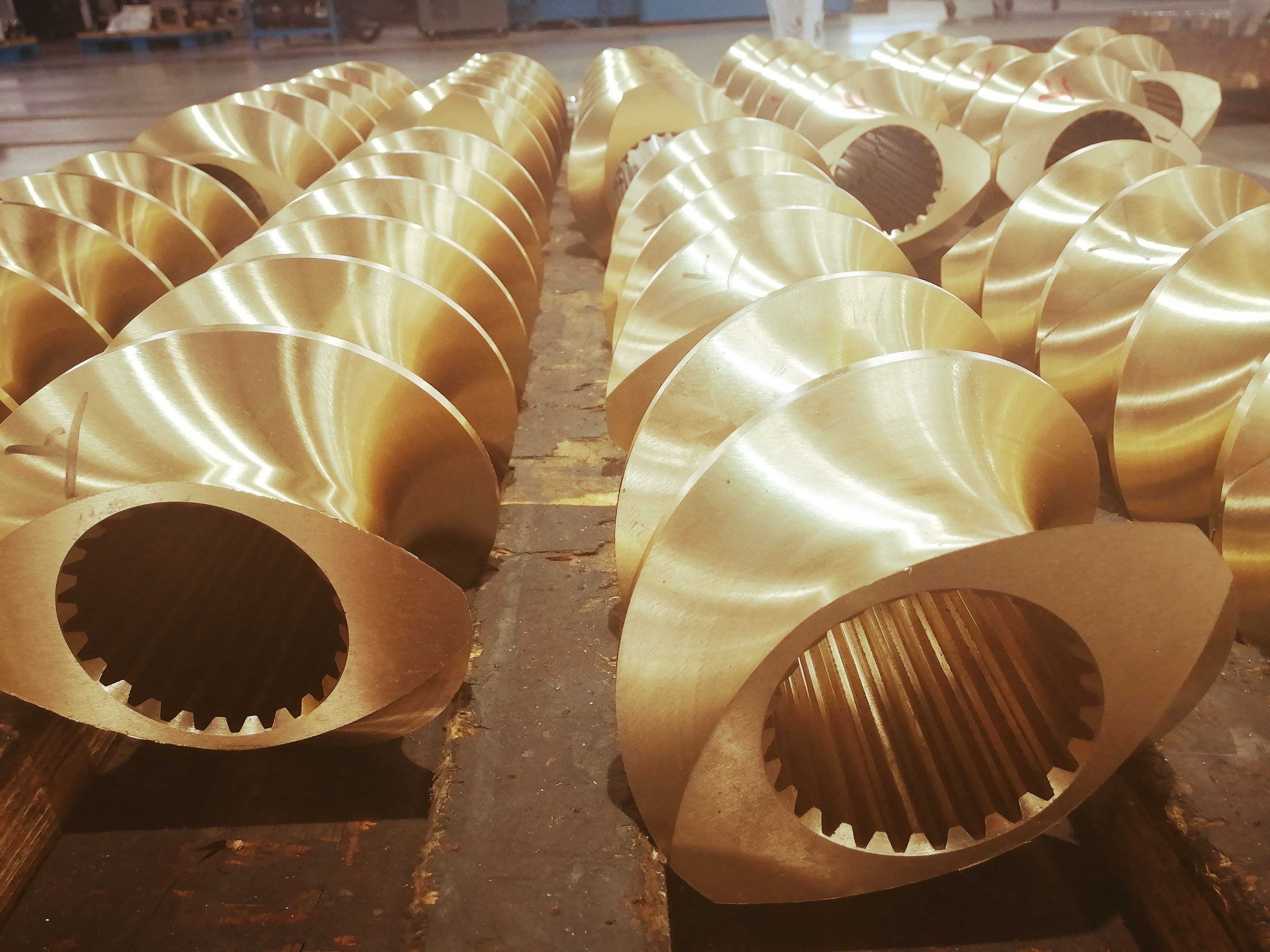

8. Product photos:

For more details,Please contact : jessica.zhang@jiangningjx.com