Chengdu Minjiang Precision Cutting Tool Co., Ltd. |

|

Verified Suppliers

|

|

General Applications

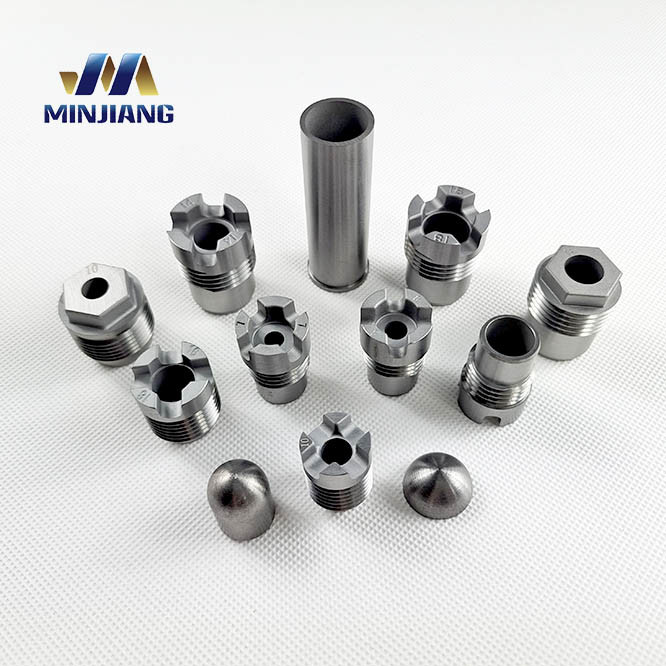

Carbide nozzles are generally used in the oil and gas, and metalworking industry. They are used to inject lubricants into the cutting tool to reduce friction and heat and to cool the cutting edges. Carbide nozzles are also used to deliver a jet of cooling fluid to parts being machined to help speed up the machining process. Finally, carbide nozzles are used in powder metallurgy to inject a stream of gas into a container of powdered metal, which is then heated, melted, and shaped into the desired product.

| Grade | ISO Grade | Chemical Composition | Physical Properties | Applications | |||||||

| WC% | CO% | Density g/cm3(±0.1) | Hardness HRA(±0.5) | TRS Mpa(min) | Grain Size(μ m) | ||||||

| YG6 | K20 | 94 | 6 | 14.85-15.00 | 90.5-92 | 1800 | 1.2-1.6 | Carbide burr. | |||

| YG6X | K15 | 94 | 6 | 14.80-15.00 | 91.7-93 | 1600 | <1.0 | High wear resistance and higher, strength. Machining of chilled alloy cast irons and refractory alloy steel or finishing of common cast irons. | |||

| YG8 | K30 | 92 | 8 | 14.62-14.82 | 89.5-91 | 1900 | 1.2-1.6 | Wire drawing die and non-standard structure and mechanical component and valve ball. | |||

| YG9 | K40 | 91 | 9 | 14.40-14.60 | 89-90 | 1850 | 1.2-1.6 | Flow sleeves, bushings, rings. | |||

| YG9C | K40 | 91 | 9 | 14.50-14.90 | 87.5-89 | 1815 | 1.2-1.6 | Nozzles, for the petroleum. | |||

| YG11 | K40 | 89 | 11 | 14.35 | 89 | 3200 | 1.6-2.0 | Nozzle, buttons, hemisphere, drilling teeth for the petroleum industry. | |||

| YG11C | - | 89 | 11 | 14.20-14.40 | 87.5-89 | 2200 | 1.6-2.4 | Inserts for mining and high-pressure nozzles in the petroleum, chemical, and mechanic industries. | |||

| YG13 | - | 87 | 13 | 14.10-14.30 | 87.5-89 | 2500 | 1.6-2.0 | Sleeves and bushings. | |||

| YG13C | - | 87 | 13 | 14.05-14.25 | 85.8-87.3 | 2550 | 2.4-4.0 | Alloy teeth and brazing bits. | |||

Related Products

Product Features

Company Concept

Innovation is an essential part of any business, offering a way to stay ahead in a competitive market. It involves taking risks and thinking critically, as well as introducing new technologies, reworking existing products and services, and creating new ideas with the potential to add value. It is a continuous process consisting of creative ideas, trial and error, and experimentation, all of which are necessary in order to develop something new and improved. Innovation is a crucial element of economic growth and can open up many opportunities for companies to succeed.

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

2. Q: What is your minimum order quantity?

A: Our minimum order quantity will vary depending on the product.

3. Q: Do you offer customized products?

A: Yes, we offer customized products to fit the client's demands.

4. Q: What payment methods do you accept?

A: We accept payment by bank transfer and Western Union.