Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

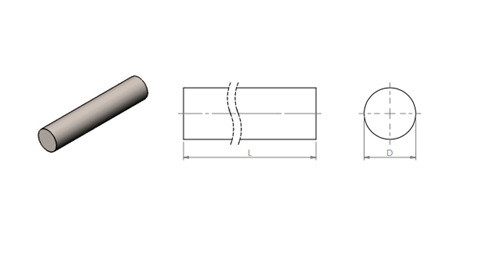

High precision YG8, YG10, YG10X Cemented Tungsten Carbide Rod

Application

Tungsten carbide rod is mainly applied in making drills, end mills and reamers. And it is also used for cutting, punching and measuring tools. It is used in the industries of paper making, package, printing, non-ferrous metal processing. Also, it is widely used processed as HSS cutting tool, carbide end mills, carbide cutting tool, NAS Cutting tool, Aerospace cutting tool, carbide drill, milling cutter core drill, high speed steel, tapered end mills, metric end mills, miniature end mills, pilot reamer, electronics cutter, step drill, double margin drill, metal cutting saw, gun barrel, angle milling cutter, carbide burrs, carbide tipped cutter etc.

The grade of YG6, YG6X, YG8 can be used for hard wood, processing original wood aluminum section bar, brass rod and cast iron, etc.YG10 is high percussion resistance, used for processing hard wood, soft wood ferrous and non-ferrous.

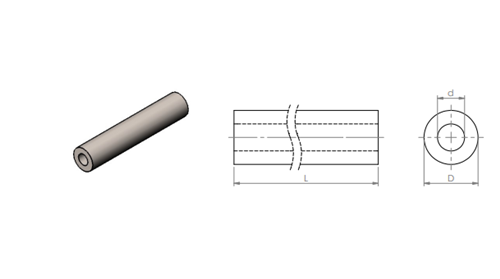

Tungsten carbide rod is manufactured as standards with one, two, or three holes, straight or twisted to a 30 or 40 degree helix, or solid with no holes. Tungsten carbide rod is mostly applied for end mill and drill with sub-micron grain grade YG10X, for non-ferrous precision cutting and wood cutting with Sub-micron grain grade YG6X, and for fibre glass reinforced plastics, titanium alloys, hardened steel with Ultra-fine grain grade YG8X etc.

Tungsten carbide rod not only can be used as cutting and drilling tools also can be used as typing needles, rollers various wear parts and structural materials. Besides, it can be extensively used in many fields, such as mechanical, chemical, petroleum, metallurgical, electronic and national defense industry.

In addition, we can provide customized with accurate appearance, size, and you can choose any tungsten carbide grade as you need. If you have any interest in tungsten carbide rod, please feel free to contact us.

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

Details Of Tumgsten Carbide Rod

| Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | OD Tolerance (mm) | ID Tolerance (mm) | Length Tolerance (mm) |

| φ2-7 | φ0.4-3.0 | 330 | +0.6 +0.2 | +0.0 -0.2 | +7.0 +3.0 |

| φ8-11 | φ0.4-7.0 | 330 | +7.0 +3.0 | +0.0 -0.2 | +7.0 +3.0 |

φ12-19+7.0

| φ0.4-10.0 | 330 | +0.9 +0.4 | +0.0 -0.3 | +7.0 +3.0 |

| φ20-30 | φ0.4-16.0 | 330 | +0.1 +0.5 | +0.0 -0.3 | +7.0 +3.0 |

| Specification D*L | Diameter Tolerance (mm) | Length Tolerance (mm) | Specification D*L | Diameter Tolerance (mm) | Length Tolerance (mm) |

| φ1.0-2.5*330 | +0.25 +0.15 | +7.0 +3.0 | φ15.9-19.5*330 | +0.60 -0.30 | +7.0 +3.0 |

| φ3.0-9.5-330 | -0.40 +0.20 | +7.0 +3.0 | φ20.0-29.5*330 | +7.0 +0.40 | +7.0 +3.0 |

| φ10.0-15.0*330 | +0.50 +0.30 | / | / | / | / |

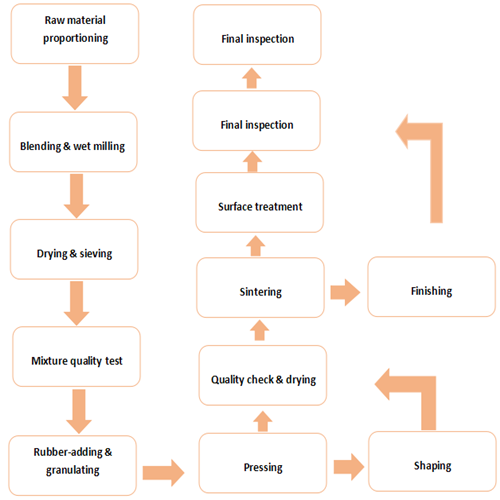

Production Process

Factory Advantage

1. we choose 100% raw material .

2. You can choose many kinds of grades for your need.

3. we have professional advanced production and testing equipments ensure high quality products.

4. Precision Ground and polished

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precision grinding.