Active Member

|

[China]

Address: No. 6 B2 Road, Zigong City, Sichuan Province

Contact name:Philippe

Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

High Precision Tungsten Carbide Mechanical Seal Ring Hydraulic Rings

Features of the carbon products for mechanical use

The carbon-graphite material for mechanical use is with excellent

self-lubrication; good resistance to chemical corrosion; relatively

high thermal conductivity and thermostability; sufficient

mechanical strength; and it is easy to be processed into all kinds

of geometrical shapes. It is widely used in various mechanical

equipment, such as: the equipped sealing elements of centrifugal

pump, immersible pump, chemical reaction kettle, water turbine, and

steam roster, etc; the piston ring, guide ring and lining equipped

on the compressor, oxygenerator and ammonia pump; shield electric

machine, submersible motor and the bearing of other mechanical

equipment and instruments, etc.

The precision seal-ring is made of high quality materials by an advanced process with serveral patented technologies, have very complicated shapes, high accuracy, stable mechanic properties, much higher wear and corrosion resistance, and a service life of more than twenty thousand hours in the normal case.

Applications

The cemented carbide seal-ring can be divided into both of the

kinetic seal-ring and static seal-ring, and constitutes mechanic

seal together with the spring, rubber seal-ring and steel jecket.

It will be used mainly for waste water pump, water discharge pump

for the mines, centrifugal pump, centrifuge, slag slurry pump and

slurry pump in the adverse working conditions of high speed

rotation, sand flush abrasion and corrosion. The seal-ring will be

installed on the pump body and rotating axle, and forms through the

end face of the kinetc and static ring a liquid or gas seal.

Grade List

| Grade | Application Mediums |

| XC100 | oli,sewage,weak acid and alkaline,light hydrocarbon,solid granules |

| XC101 | |

| XC200 | |

| XC201 | |

| XC401 | dry gas seals |

| XN100 | oil,sewage,weak acid and alkaline,light hydrocarbon,solid granules,sea water |

| XN101 | |

| XN300 | |

| XN301 | |

| XCN30 | |

| XCN31 | |

| XTP10 | oil,sewage,weak acid and alkaline,light hydrocarbon,solid granules |

| XTN10 | oil,sewage,weak acid and alkaline,light hydrocar |

| Grade | Co (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 |

| XC401 | 12.7-13.2 | 14.0-14.3 | 87.5-88.5 | 3000 |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 |

| XN300 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2100 |

| XN301 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2400 |

| XTN10 | 19.5-20.5 | 6.5-7.5 | 90.5-92.0 | 1600 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) |

| XCN 30 | 9.5-10.5 | 14.0-14.5 | 88.0-90.0 | 2400 |

| XCN31 | 9.5-10.5 | 14.0-14.5 | 88.0-90.0 | 3200 |

| XTP10 | 7.0-9.0 | 11.5-13.0 | 89.5-91.0 | 1800 |

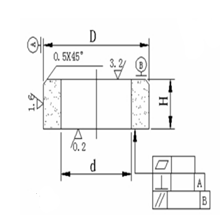

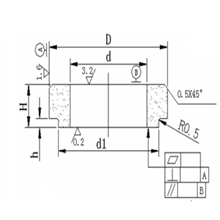

| Spec | Dimension & Tolerance | ||||||||||||

| A1 | A2 | A3 | |||||||||||

| d (H13) | D (u6) | H | d (H13) | d1 | D (u6) | H | h | d (H13) | d1 | D (u6) | H | h | |

| 18 | 19(20) | 28(26) | 5 | 19(20) | 25(26) | 28 | 5 | 1.5 | 19 | 22 | 28 | 5 | 1.5 |

| 20 | 21(22) | 30(28) | 21(22) | 27(28) | 30 | 21 | 24 | 30 | |||||

| 22 | 23(24) | 32(30) | 23(24) | 29(30) | 32 | 23 | 26 | 32 | |||||

| 24 | 25(26) | 35(32) | 25(26) | 31(32) | 35 | 25 | 29 | 35 | |||||

| 25 | 26(28) | 36(34) | 26(28) | 32(34) | 36 | 26 | 30 | 36 | |||||

| 28 | 29(31) | 39(37) | 6 | 29(31) | 35(37) | 39 | 6 | 29 | 33 | 39 | 6 | ||

| 30 | 31(33) | 41(39) | 31(33) | 37(39) | 41 | 31 | 35 | 41 | |||||

| 32 | 33(36) | 43(42) | 33(36) | 39(42) | 43 | 33 | 37 | 43 | |||||

| 33 | 34(36) | 44(42) | 34(36) | 40(42) | 44 | 34 | 38 | 44 | |||||

| 35 | 36(38) | 46(44) | 36(38) | 42(44) | 46 | 36 | 40 | 46 | |||||

| 38 | 39(41) | 50(47) | 39(41) | 45(47) | 50 | 39 | 44 | 50 | |||||

| 40 | 41(43) | 52(49) | 41(43) | 47(49) | 52 | 41 | 46 | 52 | |||||

| 43 | 44(46) | 55(52) | 44(46) | 50(52) | 55 | 44 | 49 | 55 | |||||

| 45 | 46(48) | 57(54) | 46(48) | 52(54) | 57 | 46 | 51 | 57 | |||||

| 48 | 49(51) | 60(57) | 49(51) | 55(57) | 60 | 49 | 54 | 60 | |||||

| 50 | 51(53) | 62(59) | 51(53) | 57(59) | 62 | 51 | 56 | 62 | |||||

| 53 | 54(56) | 65(62) | 54(56) | 60(62) | 65 | 54 | 59 | 65 | |||||

| 55 | 56(58) | 67(64) | 56(58) | 62(64) | 67 | 56 | 61 | 67 | |||||

| Spec | Dimension & Tolerance | |||||||

| D -0.2 | D (H13) | d1 (h8) | L | L1 | h1 | h | Rubber ring cross-sectionnal diameter | |

| 18 | 32.7 | 19 | 26.7 | 20 | 8.5 | 6.5 | 4 | 3.55 |

| 20 | 34.7 | 21 | 28.7 | |||||

| 22 | 36.7 | 23 | 30.7 | |||||

| 24 | 38.7 | 25 | 32.7 | |||||

| 25 | 39.7 | 26 | 33.7 | |||||

| 28 | 42.7 | 29 | 36.7 | |||||

| 30 | 44.7 | 31 | 38.7 | |||||

| 32 | 47.7 | 33 | 41.7 | |||||

| 33 | 47.7 | 34 | 41.7 | |||||

| 35 | 49.7 | 36 | 43.7 | |||||

| 38 | 55.7 | 39 | 48.7 | 21 | 8.9 | 5 | 4.1 | |

| 40 | 57.7 | 41 | 50.7 | |||||

| 43 | 60.7 | 44 | 53.7 | |||||

| 45 | 62.7 | 46 | 55.7 | |||||

| 48 | 65.7 | 49 | 58.7 | |||||

| 50 | 69.7 | 51 | 61.7 | 21.5 | 8.8 | 4.7 | ||

| 53 | 72.7 | 54 | 64.7 | |||||

| 55 | 74.7 | 56 | 66.7 | |||||

| 58 | 77.7 | 59 | 69.7 | |||||

| 60 | 79.7 | 61 | 71.7 | |||||

| 63 | 82.7 | 64 | 74.7 | |||||

| 65 | 84.7 | 66 | 76.7 | |||||

| 68 | 89.7 | 69 | 80.6 | |||||

| 70 | 91.7 | 71 | 82.6 | 22.5 | 9.2 | 5.3 | ||

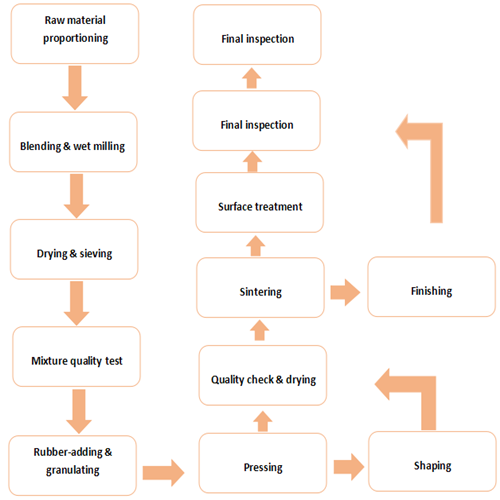

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.