Active Member

|

[China]

Address: No. 6 B2 Road, Zigong City, Sichuan Province

Contact name:Philippe

Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

YG6,YG8,YG10 Customized Tungsten Carbide Nozzle Tungsten Carbide Water Jet Nozzle

Tungsten Carbide Water Jet Nozzle

Features

Need less maintenance, High hardness, low density and excellent

wear and anti-corrosion,

Usage

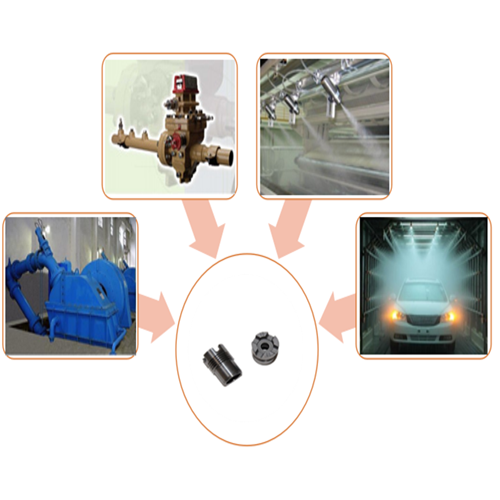

Tungsten carbide water jet nozzle has been widely used inwater jet and shot peening equipment, offering a long life with optimum air and abrasive use.

Cemented carbide nozzle is mainly used in chemical, food, machinery, metallurgy, construction and other industries to produce powder, remove rust, clean, atomize, etc.. There are more than 800 specifications’ hard alloy nozzles. It is preferred environment-friendly product for factories who have cement and other working environment and have serious dust pollution to remove dust and pollution. All kinds of atomized discs have precise sizes and shapes, fine atomized particle sizes and full combustion. Hard alloy nozzle is used in oil-fired heating furnace, industrial furnace of oil burning boiler and other heating furnace for special use. We also can produce customized hard alloy nozzles according to drawings. Materials of hard alloy nozzle are YG6,YG8,YG11,YWN8.

Nozzles are built to speed the flow of gases, liquids and slurries of virtually any viscosity and to withstand punishing wear, erosion and/or chemical attack in harsh chemical and powder service environments. They have proved to be a high performance, long-lasting alternative to hard steel.

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 |

| XTN10 | 19.5-20.5 | 6.5-7.5 | 90.5-92.0 | 2800 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XTT50 | 14.0-15.0 | 8.9-9.5 | 89.0-91.0 | 1600 |

| XTP10 | 7.0-9.0 | 11.5-13.0 | 89.5-91.0 | 1800 |

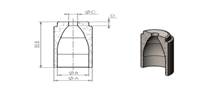

Details Of Tumgsten Carbide Nozzle

| Type | Dimension (mm) | |||

| φC ±0.15 | φA ±0.15 | φB±0.15 | φD ±0.15 | |

| XJO1-64 | 6.4 | 20.3 | 15.8 | 6.4 |

| XJO1-71 | 7.1 | 20.3 | 15.8 | 7.1 |

| XJO1-86 | 8.6 | 20.3 | 15.8 | 8.6 |

| XJO1-94 | 9.4 | 20.3 | 15.8 | 9.4 |

| XJO1-109 | 10.9 | 20.3 | 15.8 | 10.9 |

| XJO1-117 | 11.7 | 20.3 | 15.8 | 11.7 |

| XJO1-127 | 12.7 | 20.3 | 15.8 | 12.7 |

| XJO1-142 | 14.2 | 20.3 | 15.8 | 14.2 |

| Type | |||

| φB | φA(φD) | φC | |

| XJ02-64 | 6.4 | 18.8 | 14.73 |

| XJ02-71 | 7.1 | 18.8 | 14.73 |

| XJ02-86 | 8.6 | 18.8 | 14.73 |

| XJ02-94 | 9.4 | 18.8 | 14.73 |

| XJ02-109 | 10.9 | 18.8 | 14.73 |

| XJ02-117 | 11.7 | 18.8 | 14.73 |

| XJ02-127 | 12.7 | 18.8 | 14.73 |

| Type | Dimension (mm) | ||||||||

| φA ±0.25 | φB ±0.25 | φC ±0.25 | φD ±0.20 | φE ±0.20 | F ±1 | G ±1 | M ±1 | K ±0.5 | |

| XP01-1 | 24.5 | 30.0 | 5.0 | 9.0 | 18.0 | 50.0 | 69.0 | 21.0 | 130.0 |

| XP01-2 | 24.5 | 30.0 | 8.0 | 12.5 | 20.0 | 50.0 | 69.0 | 21.0 | 140.0 |

| XP01-3 | 24.5 | 30.0 | 10.0 | 13.5 | 21.0 | 50.0 | 69.0 | 21.0 | 170.0 |

| XP01-4 | 24.5 | 30.0 | 13.0 | 19.5 | 27.0 | 50.0 | 69.0 | 21.0 | 226.0 |

| XP01-5 | 30.0 | 36.0 | 6.5 | 12.5 | 19.5 | 54.0 | 70.0 | 20.0 | 130.4 |

| XP01-6 | 30.0 | 36.0 | 8.0 | 12.5 | 12.5 | 54.0 | 70.0 | 20.0 | 141.0 |

| XP01-7 | 30.0 | 36.0 | 11.0 | 15.0 | 12.5 | 55.0 | 69.0 | 21.0 | 200.0 |

| Type | Dimension (mm) | ||||||

| φA ±0.25 | φB ±0.25 | φC ±0.20 | φD ±0.20 | φE ±0.25 | F ±2 | K ±0.5 | |

| XP02-1 | 32.0 | 25.0 | 6.2 | 8.0 | 16.0 | 45.0 | 78.0 |

| XP02-2 | 32.0 | 25.0 | 8.0 | 10.0 | 18.0 | 45.0 | 78.0 |

| XP02-3 | 32.0 | 25.0 | 11.0 | 13.0 | 21.0 | 45.0 | 78.0 |

| XP02-4 | 38.0 | 32.0 | 6.2 | 6.2 | 16.0 | 45.0 | 80.0 |

| XP02-5 | 38.0 | 32.0 | 8.0 | 8.0 | 18.0 | 45.0 | 80.0 |

Product Application Scene

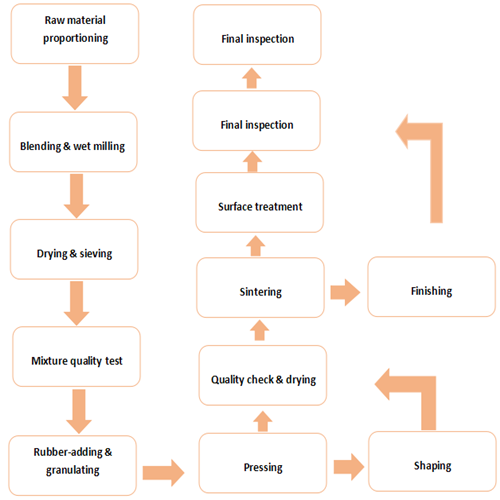

Production Process

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is

25-35 days if the goods are not in stock, it is according to

quantity.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q4: What is your terms of payment ?

A4: Payment<1000USD, 100% in advance. Payment>1000USD, 30%

T/T in advance ,balance before shipment.