Zhejiang Jiangchao Technology Co., Ltd |

|

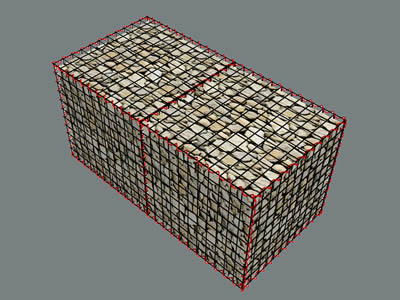

Welded Gabion Box for Protection and Decoration Gabion Basket shore

protection

Welded gabion box is widely used in retaining wall structures,

rockfall and soil protection and so on. Welded gabions are filled

on site with hard and durable stone to form mass gravity

structures. And welded gabions are quicker and simpler to install

than woven mesh gabions.

In more applications, the welded gabion box can be made into

different sizes and shapes for decoration applications. They can be

made into gabion pot, staircase, table and bench, postbox. It can

also be used to form particular landscapes, such as waterfall,

fireplace and decorative wall.

Material of welded gabion box

Welded gabion box is manufactured from cold steel wire for tensile

strength. It is electrically welded together then hot dipped

galvanized or PVC coating, ensuring a longer life and better

corrosion and rust resistance performance. There are galvanized

welded gabion and PVC welded gabions. Gabion boxes are designed on

the principle of mass earth retaining wall. The strength of the

wire mesh helps to with stand the forces generated by the retained

soil.

WGB-01: Welded gabion can be made into various artwork to

decorate.the city.

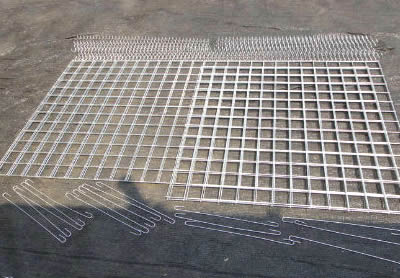

WGB-02: Galvanized welded gabion.

WGB-03: PVC coating gabion.

Connection types of welded gabion box

Welded gabion box can be connected in different method with

different accessories. Here are the detailed accessories and

connection method, refer to them and choose the perfect one

suitable for you.

Spiral wire connection.

U clip connection.

C ring connection.

Lacing wire connection.

Hook connection.

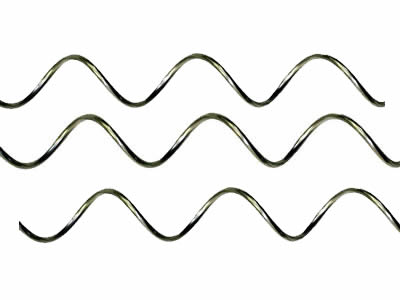

WGB-04: Spiral wire.

WGB-05: Spiral wire connection.

WGB-06: U clip.

WGB-07: U clip connection.

WGB-08: C ring.

WGB-09: C ring connection.

WGB-10: Lacing wire connection.

WGB-11: Hook connection.

Specifications

Material: galvanized wire, Galfan coated wire or PVC coating wire.

Wire diameter: 14 G - 23 G.

Mesh size: 1/4", 1/2", 3/8", 3/4", 1", 2", 3", etc.

Box size: 2 m × 1 m × 1 m, 2 m × 1 m × 0.5 m, 1 m × 1 m × 1 m, 1 m × 1 m × 0.5 m, 1.5 m × 1 m × 1 m.

Nominal box sizes | No. of diaphragms | Capacity per box |

|---|---|---|

1.0 × 1.0 × 0.5 | Nil | 0.50 |

1.0 × 1.0 × 1.0 | Nil | 1.00 |

1.5 × 1.0 × 0.5 | Nil | 0.75 |

1.5 × 1.0 × 1.0 | Nil | 1.50 |

2.0 × 1.0 × 0.5 | 1 | 1.00 |

2.0 × 1.0 × 1.0 | 1 | 2.00 |

3.0 × 1.0 × 0.5 | 2 | 1.50 |

3.0 × 1.0 × 1.0 | 2 | 3.00 |

4.0 × 1.0 × 0.5 | 3 | 2.00 |

4.0 × 1.0 × 1.0 | 3 | 4.00 |

Welded gabion box advantages:

Blends easily and harmoniously with the natural surroundings.

Low cost alternative to concrete or masonry structures.

Very high resistance to natural forces due to better tensile strength.

Can withstand any unpredictable movement or settlement without loss of stability.

Simple and speedy installation, making it cost effective.

Quality finish and appearance is more aesthetically pleasing.

More rigid than woven mesh resulting in a more uniform finish when built.

Quicker and cheaper to install than woven mesh gabions because no pre-stretching required.

Special gabions sizes and mesh such as gabions with 4 mm front mesh and 3 mm mesh else can be available.

Welded gabion box applications:

Protective application.

Retaining wall.

Slope protection.

River channel controlling.

Military defense.

Noise barrier wall.

Bridge protection.

Soil strengthening.

Coastal protection.

Flood controlling.

Landscape construction.

Gabion bench.

Gabion planter.

Fireplaces.

Gabion staircase.

Gabion pot.

Gabion partition wall.

Gabion barbecue.

Gabion waterfall.

Gabion flower pot.

WGB-12: Welded gabion is used for slope protection.

WGB-13: Welded gabion is used for soil strengthening.

WGB-14: Welded gabion is used for coastal protection.

WGB-15: Welded gabion is used for military defense.

WGB-16: Welded gabion is used for gabion table and bench.

WGB-17: Welded gabion is used for staircase.

WGB-18: Welded gabion is used for waterfall.

WGB-19: Welded gabion is used for gabion pot.

How to install welded gabion box?

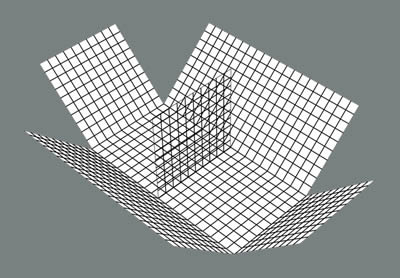

Erect ends, diaphragms, front and back panels on the bottom section of gabion.

Fasten each parts of gabion through the mesh opening in adjacent panels with spiral wires, C ring, U clip and other connection method.

Install the stiffeners. The stiffeners shall be places across the corners, at 300 mm from the center. Providing a diagonal bracing and crimped over the line and cross wires on the front and side faces. It is no need n the interior cells.

Fill the welded gabion with stones, sands, soils, woods and other materials.

Close the lid and secure in the same way with the step 2 connection method.

When stacking tiers of the welded gabion box, the lid of the lower tier may serve as the base of the upper tier. Secure with spiral binders and add pre-formed stiffeners to exterior cells before filling with graded stones.

WGB-20: Installation preparation.

WGB-21: Erecting the components of welded gabion.

WGB-22: Fasten each parts of welded gabion with spiral wire.

WGB-23: Install the stiffeners.

WGB-24: Fill the welded gabion with stones.

WGB-25: Install the lid to the welded gabion and project completed.