Baseti International Trading Co., Ltd. |

|

Verified Suppliers

|

|

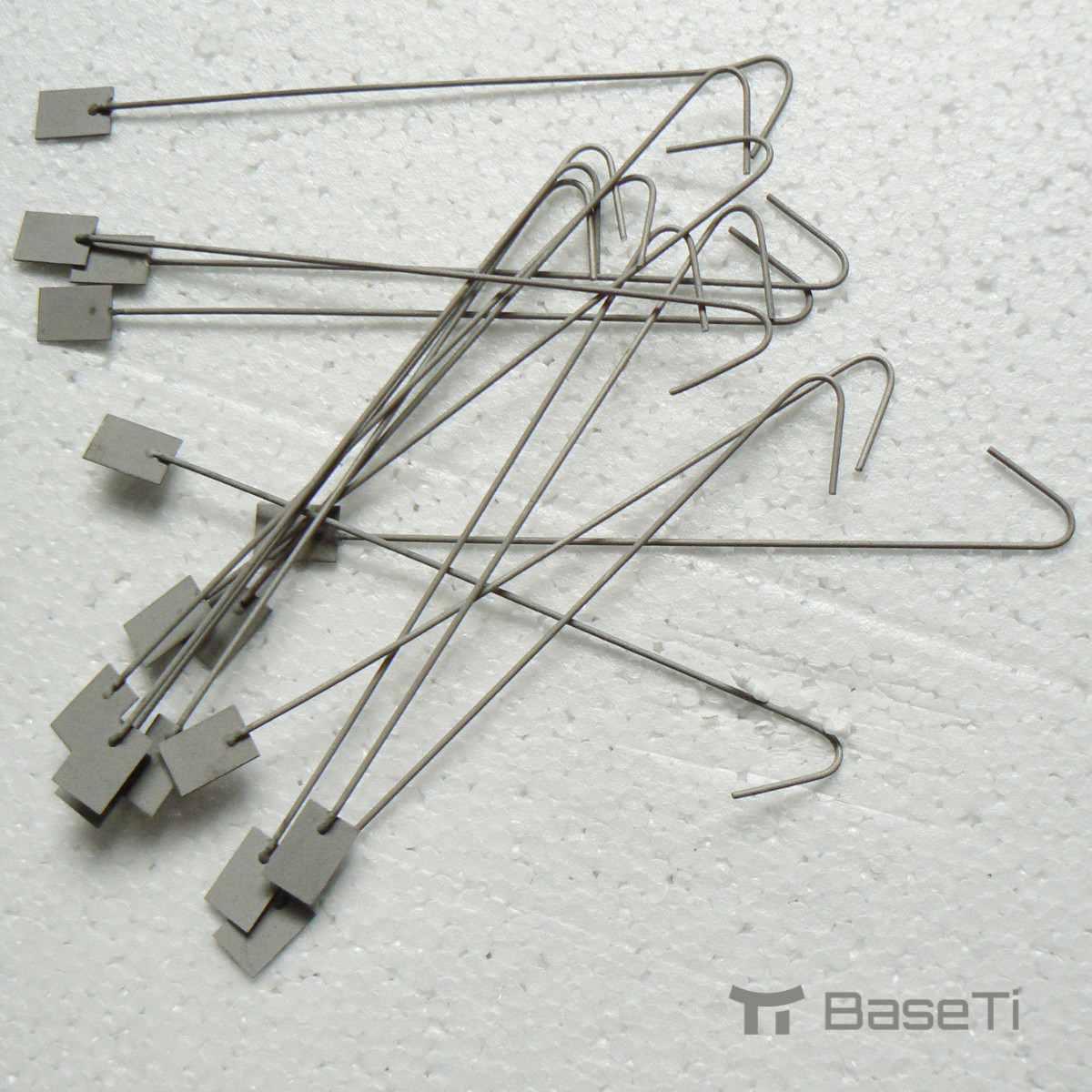

Platinum Coated Titanium Anode Mesh Chlor-Alkali Production Water Treatment And Disinfection

The platinum coating on the titanium anode mesh is what distinguishes it from other anodes. Platinum, a precious metal known for its superior conductivity and exceptional resistance to corrosion, forms a thin but robust layer on the titanium substrate. This unique combination harnesses the strength of titanium with the electrochemical advantages of platinum, providing an optimal balance between efficiency and longevity.

Platinum Coated Titanium Anode Meshes are an ideal solution for applications that demand high conductivity and corrosion resistance. Their primary use lies in electrolysis processes, where they facilitate the efficient breakdown of compounds. They are especially significant in chlor-alkali production, electroplating, and water treatment processes.

This anode mesh boasts unparalleled performance due to its platinum coating. It ensures consistent current distribution, leading to efficient operations and reduced energy costs. Moreover, its resistance to passivation prevents it from becoming less effective over time.

At BaseTi, we ensure our Platinum Coated Titanium Anode Mesh adheres to the highest international standards. If a specific grade or standard is required that might not be standard in our offerings, clients should know that our titanium electrode factory is adept at customizing to meet unique requirements.

When it comes to reliability and performance, BaseTi stands out as the preferred titanium electrode manufacturer and supplier in the industry. Trust in our expertise for top-notch solutions in all electrochemical processes.

Q: Eyeing the model XX titanium anode?

A: BaseTi thrives on customization. Instead of predefined models,

we mold anodes as per your exact design requisites.

Q: Can our XX equipment have a specially designed anode?

A: Certainly! Whatever your equipment type, BaseTi can customize

the perfect anode. Just share the design details.

Q: What's the most fitting anode coating for us?

A: Let's understand your industry better. We'll then guide you to

the ideal coating choice.

Q: Operating current and voltage for BaseTi anodes?

A: They're versatile. Key operational metrics to consider:

Current density: ≤2000 A/M²

Temperature: 40-60°C

Steering clear of fluoride/cyanide ions in electrolytes is crucial.

Q: How long do these anodes last?

A: Durability is industry-dependent. You're looking at anywhere

from 6 months up to 50 years. We'll assure a certain lifespan based

on your industry.

Coating Type | Conductivity (S/m) | Corrosion Resistance | Lifetime (Years) | Application Fields |

|---|---|---|---|---|

Mixed Metal Oxide (MMO) | 1.5 x 10^6 | High | 5-7 | Electrochlorination, Water Treatment |

Ruthenium Iridium (Ru-Ir) | 1.3 x 10^6 | Very High | 7-9 | Electroplating, Chlor-Alkali Process |

Platinum | 9.43 x 10^6 | Extremely High | 8-10 | Cathodic Protection, Hydrogen Evolution |

Note: The above table provides an overview based on typical American and European standards. The exact physical properties might vary depending on the specific product and manufacturer.

Coating (Abbreviated) | Conductivity (S/m) | Corrosion Resistance | Lifetime (Years) | Application Fields |

|---|---|---|---|---|

MMO | 1.5 x 10^6 | High | 5-7 | Electrochlorination, Water Treatment |

Ru-Ir | 1.3 x 10^6 | Very High | 7-9 | Electroplating, Chlor-Alkali Process |

Pt | 9.43 x 10^6 | Extremely High | 8-10 | Cathodic Protection, Hydrogen Evolution |

Note: This table provides a summary based on typical standards from the USA and Europe. Actual properties might differ according to the specific product or manufacturer.