Shenzhen Kunhe Precision Hardware Co., Ltd. |

|

Verified Suppliers

|

|

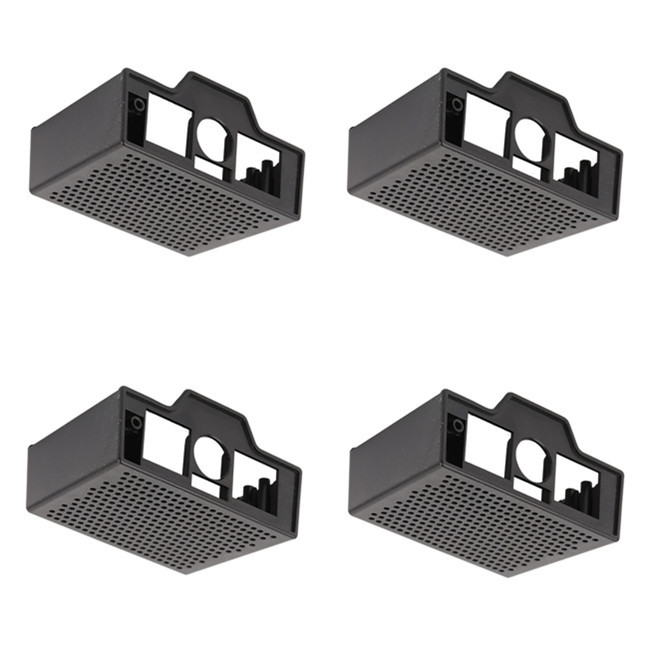

Factory price plastic injectioin molding manufacturing parts ODM OEM for cover PS precison component

Precision is key when it comes to creating plastic molding parts for covers. Our ODM Precision Plastic Molding Parts use polystyrene injection molding technology to ensure that you can have the perfect covers for your products. Here are some key features of our ODM Precision Plastic Molding Parts:

Specification:

| items | description |

| product name | stamping, deep stamping, bending, punching, threading, welding, tapping, riveting |

| material | aluminum, copper, brass, stainless, steel, iron, alloy, zinc etc. |

| finish | polish, anodize, sandpowder coating, vacuum plating, nickel, zinc, tin, silver plating etc. |

| Usage | all kinds of cars, machinery, home appliance, electronic product, electric appliance, stationery, compueter, power switch, miniature switch, architectures, commodity and AV equipment, sports equipment and gift crafts |

| machining equipment | CNC milling and lathe and process center machining and grinding, laser cutting,CNC bending, Riveting, welding, polishing, assembly and packing |

| drawing file format | solidworks, PROE, CAD, PDF, JPG |

| inspections | IQC, IPQC, FQC, QA |

Our Service:

================================================================================

Customized OEM manufacturing Advantages:

Accepted OEM customized manufacturing to make the production for all orders. real factory for over 20 years manufacturing experience, is OK to do OEM, customized, one -stop manufacturing, with own workshops for precison machining, precision stamping, precision MIM, precison plastic, and blade sharpening and QC assembly center.

accepted customized to all metal related project and product

product picture details and features:

Package and packing: 1. as client instructed finish packing by insert card clampshell + insert card, 2 loose packing by bubble material wraped ito inner case then by big master carton, 3. foam die+ plastic bag+ carton box + pallet, 4. foam material + inner bag + wooden box.

Manufacturing process: CNC stamping, CNC lathe, CNC milling, CNC machining, laser cutting, CNC MIM.