Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

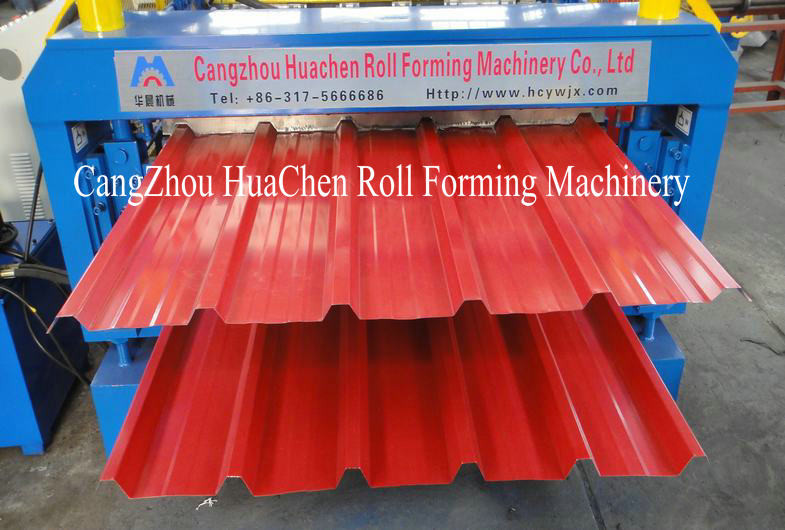

PLC Control Double Layer Roof Panel Roll Forming Machine , High

Grade 45# Steel Sheet

Being counted amongst the most prominent entities of the market, we

are engaged in offering a best quality range of Double Layer Roof Forming Machine which finds application in production of false ceiling section

profiles, cable trays and DIN rails. The offered roll forming

roofing product is valued for easy usage, high strength, corrosion

& thermal resistance and easy installation. This Double Layer Roof Forming Machine is manufactured at our state-of-the-art manufacturing unit using

high grade raw materials and cutting-edge technology in line with

global set industry norms.

Quick Detail:

1. Suitable to process: Color steel plate

2. Width of the plate: 1250mm

3. Rollers: 10/17 rows

4. Dimensions: 9.7*1.55*1.91m

5. Power: 4+4kw

6. Rolling material: high grade 45# steel(plated chrome on surface)

7. Thickness of the plate:0.3-0.6mm

8. Voltage: 380V 50Hz 3phases

9. Material of the cutting plate: Cr12

10. Hydraulic: 40#

11. Processing precision: Within 1.00mm

12. Control system: PLC control

Description:

Double layer roll forming machine Main parameter

No. | Main parameter of Double layer roll forming machine | |

1 | Suitable to process | Color steel plate |

2 | Width of the plate | 1250mm |

3 | Rollers | upper level :10 rows |

4 | Dimensions | 9700*1550*1910mm |

5 | Power | 4+4kw |

6 | Rolling material | high grade 45# steel(plated chrome on surface) |

6 | Thickness of the plate | 0.3-0.6mm |

7 | Productivity | 20m/min |

8 | Diameter of the roller | Φ70mm |

9 | Voltage | 380V 50Hz 3phases |

10 | Material of the cutting plate | Cr12 |

11 | Hydraulic | 40# |

12 | Processing precision | Within 1.00mm |

13 | Control system | PLC control |

Equipment components: Man-made uncoiler-roll forming machine-computer control system-hydraulic

control system- cutting

Application

This kind of machine make two types of tile together perfectly, it

has reasonable structure, beautiful appearance, with advantage of

saving space, easy operate and especially welcomed by the

customer with limit area or site

Competitive Advantage

1. CE certification

2. noiseless

3. easy operate

4. high output

5. easy maintain