Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

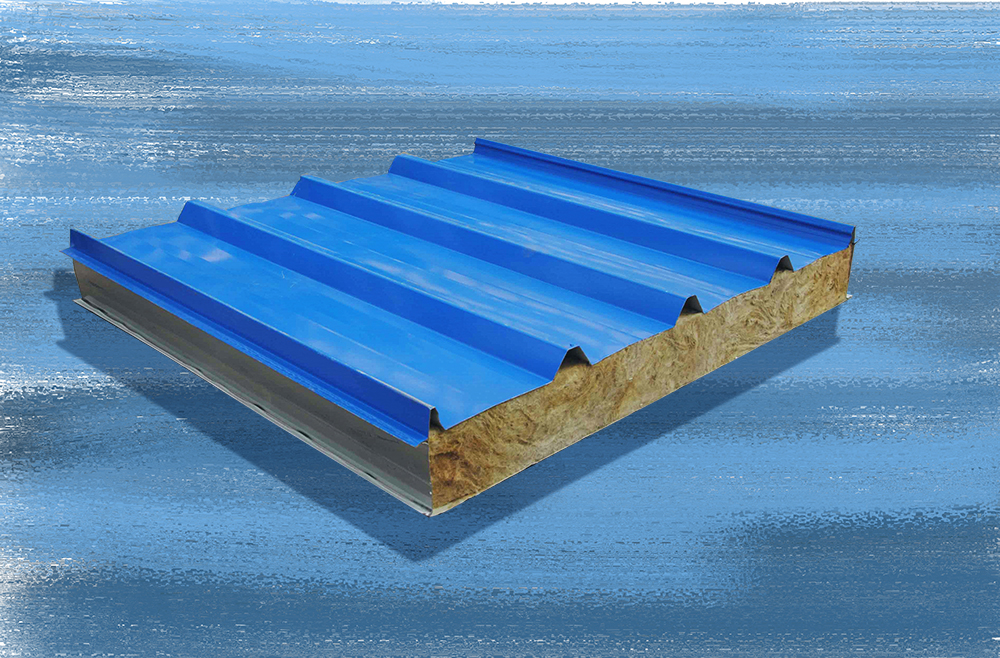

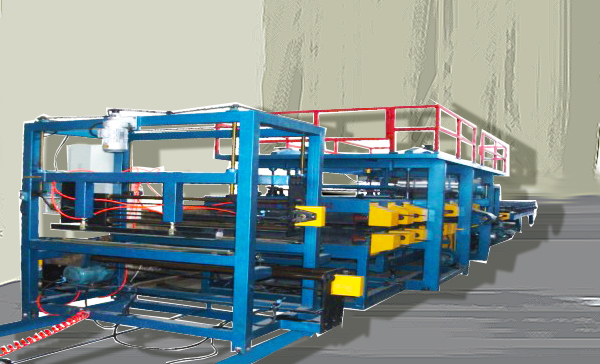

mineral wool board Sandwich color sheet panel roll forming machine

Parameters of pressure dispensing machine for thermal insulation color steel equipment:

1. Compressor captain, width and height: 9500mmX 1500mm X1200mm.

2.The fuselage frame is welded with 300H steel (the legs are easy to disassemble)

3. The pressure roller is # 45 steel, and the surface is hard chromium-plated 0.05mm boards are not easy to paint

4. Wall plate type is adopted, and the thickness of vertical plate is 12mm

5. The press shaft is made of # 45 round steel with a diameter of 70mm

6. Transmission mode :1 inch chain wheel and chain

7. Power: host 3KW with cycloidal reducer

8. Number of molding rows: row 13 -- 15 (the row depends on the selected model)

9. Compression thickness :0.2-0.8mm

Press width: 1200mm

The main body of the composite board is composed of feeding platform, forming host, forming shearing device, hydraulic station and computer control system.The optional equipment includes general discharge machine, hydraulic discharge machine, automatic cutting machine, etc.

Main technical parameters of compound plate bottom machine

1. Installation size: 9000mm * 1700mm * 1600mm

2. Number of molding channels: 8 channels

3. Roller material: # 45 steel

4. Roller plating thickness: 0.05mm

5. Cutting tool material: Cr12

6. Electric control system: PLC adopts touch screen, and frequency converter adopts taida.

7. Press thickness: 0.3-0.8mm

8. Advantages of the machine: smooth surface, no abrasion, and firm adhesion.

9. Power supply: AC380V/ 50-60hz

10. Material releasing frame: it is composed of bracket and material releasing coil core, bearing 5-7 tons

11. Tile pressing machine: it is formed into 13 rows of shafts, with the shaft: saving 70, middle plate: 12mm, chain wheel and chain: 6 minutes

12. Compound host: square tube: 80*160*6, glue shaft: 150, 23

At least 5 people are required to operate the machine

The main body of the composite board is composed of feeding platform, forming host, forming shearing device, hydraulic station and computer control system.The optional equipment includes general discharge machine, hydraulic discharge machine, automatic cutting machine, etc.

Main technical parameters of compound plate bottom machine

1. Installation size: 9000mm * 1700mm * 1600mm

2. Number of molding channels: 8 channels

3. Roller material: # 45 steel

4. Roller plating thickness: 0.05mm

5. Cutting tool material: Cr12

6. Molding speed: 9-10m/min.

7. Electric control system: industrial computer PLC control

8. Frequency converter: the function of counting accurate anti-band knife (optional)

9. Host power: 3kw

10. Hydraulic station power: 3kw

11. Plate thickness: 0.4-0.7mm

12. Sheet width: 1000/1200mm