Cyg Tefa Co., Ltd. |

|

Verified Suppliers

|

|

Advantages

1.Closed Cell

2.Very Lightweight

3.Non-abrasive

4.Easy to fabricate

5.Non-dusting

6.Superb strength and tear resistance

7.Excellent shock absorption & vibration dampening properties

8.Resistant to water, chemicals, solvents & grease

9.CFC free

10.Recyclable

11.Odorless

12.Excellent buoyancy

13.Very cost-effective

14.Excellent thermal insulation properties

| PE Foam Brief Introduction | ||

| Product name | Xpe foam | Ixpe foam |

| Material | Ldpe,(low density polyethylene foam) Ac foaming agent,cross-linking agent,etc | Ldpe,(low density polyethylene foam) Ac foaming agent,etc |

| Structure | Closed cell,cross-linked(by cross-linking agent) | Closed cell,cross-linked(irradiated) |

| Density | 25~330 kg/m3 | 25~330 kg/m3 |

| One layer thickness | 2mm~3mm(Density:67~330kg/m3) | 0.5~10mm(Density:25~330kg/m3) |

| Laminated thickness | 1)10mm(25~100kg/m3) 2)12mm(25~40kg/m3) 3)customized | Customized |

| Laminated with | Pe foam/Pure Alu/Aluminizing | |

| Size | customized | |

| Color | Normal is black,white,gray. Other color can be customized. | |

| Shape | Roll or sheet | |

| Adhesive | Available | |

| Fire resistance | Available (UL94-1) | |

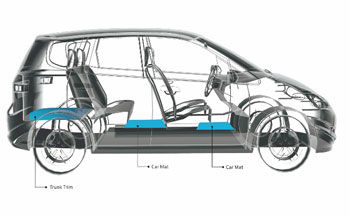

Material: XPE, IXPE Foam

Density: 10B (100 kg/m³), 15B (66 kg/m³)

Thickness: 5mm, 6mm, 7mm

Processing method: Heat pressing and seaming

Advantage: It's used in the middle layer of car floor. The most

common product is combination of PVC materials. Easy to process and

laminate with other materials to enhance waterproof and insulating

properties.

Material: XPE, IXPE Foam

Density: 20B (50 kg/m³), 25B (40 kg/m³), 30B (33 kg/m³)

Thickness: 5mm

Processing method: Heat pressing

Advantage: Excellent insulation materials and building-up

properties.

3. Thermal insulation and soundproofing material for car

Material: XPE

Density: 30B (33 kg/m³)

Thickness: 3mm, 4mm, 5mm

Processing method: Adhesive (Included)

Advantage: Adhesive foam for easy decroration, have good soundproof

and thermal insulation performance. Fire retardant is available.

Material: IXPE, IXPP

Density: 15B(66 kg/m³)

Thickness: 4mm, 5mm

Processing method: Heat pressing & die cutting

Advantage: Processing with flexible IXPE or IXPP foam material to prevent vibration and reduce the heat.

Material: IXPE, XPE Foam

Density: 30B (33 kg/m³), 35B(28 kg/m³)

Thickness: 3mm, 4mm, 5mm, 6mm

Processing method: Heat pressing

Advantage: Extremely easy to cut into the size you want with

shockproof protection and noise reduction properties.

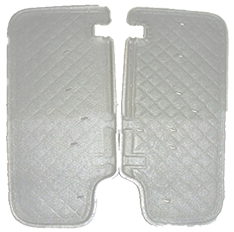

Material: XPE, IXPE Foam

Density: 8B (125 kg/m³), 10B (100 kg/m³), 15B (66 kg/m³), 20B (50

kg/m³)

Thickness: 2mm, 3mm, 4mm

Application: Door waterproof strip, water-repellent film

Processing method: Thermal vacuum forming

Advantage: The closed cell foam structure provides noise reduction

and excellent waterproof property.

Company info

CYG TEFA offers the best solution for polyethylene foam production

based on long experience in the developing ,manufacturing PE

foam.All the service are focused on quality of products and

satisfied our customer.

We are committed to developing,manufacturing and selling

cross-linked PE foam.

Over the years,we have developed 2 production bases in Shenzhen,Hangzhou,and 17 production lines of all kinds,with annual production capacity of 6000 tons