Suzhou Polywell Engineering Plastics Co.,Ltd |

|

Verified Suppliers

|

|

What does a plastic extruder do?

Plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired additives, is melted and formed in a continuous process. The raw material (polymer) in the form of granulates, is gravity fed into the hopper and through the feed throat, drops on a rotating screw.

What is the raw material of PA plastic profile extrusion machine?

Polyamide6.6 granules reinforced by 25% glass fiber.

What is included in the PA plastic profile production line?

1. PA strips extrusion machine with automatic feeding machine and hopper dryer

2. PA plastic moulds and dies

3. Cutting machine

4. Worktable or winder

What plastics can be extruded?

There are more than 20 different types of thermoplastics that can be extruded. Some of the more common ones include polyethylene, polypropylene, polystyrene, polycarbonate, PVC and ABS, all of which can be easily heated and then pressured in a mould to form different plastic profiles, tubes and sections.

But we mainly sell PA6.6 gf25 heat insulation profile extrusion machine.

Advantages of extrusion

The extrusion process is fast and efficient at producing continuous shapes in varying lengths. Products can be produced in large volumes, and there is minimal wastage. Complex shapes can be produced with varying thickness, textures, colors etc.

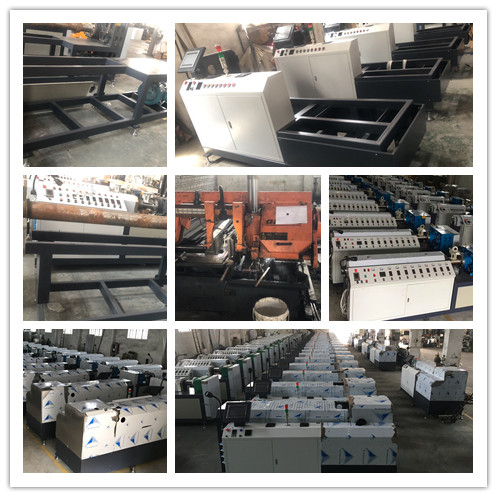

Detailed Images

| Production Speed | Around 8-14cm/min |

|---|---|

| Strip Shape | All kinds of shape |

| Raw Material | PA6.6 granules reinforced by 25% glass fiber |

| Cooling | Water Cooling |

| Usage | Produce thermal break strip |

| Type | Plastic extrusion machine |

| Winding Machine | Available |

| Cutting Machine | Available |

| Worktable | Available |

Welcome to visit our company!

Please feel free to contact us if you have any questions.

Camille

E-mail:camille@thermalbreak-strip.com

Phone:0086-13584481777 (WhatsApp)

Wechat:Camille_4790

Our Service

Choosing Polywell means choosing the certainty of a reliable partner, able to team up and offer daily support. We are where you need us, whenever you need us.

Q: What is your MOQ for the polyamide strip extrusion machine?

A: 1 set.

Q: As new player of polyamide strips extrusion, how we learn to use the machine?

A: Polywell will provide paper and videos files to help customer operate the machine. If customer needs, we can also provide on site training service.

Q: Can we customize and buy the raw materials and molds?

A: We can provide every product related to the polyamide thermal break profiles production. Including the raw material, the mold, the cutting machine, the worktable, the winder and so on.

Q: What is the warranty for your machine?

A: For extruder machine, it is one year. We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately.

Q: What is your payment terms?

A: 50% T/T deposit before production, 50% T/T balance before loading.

Packaging | |

|---|---|

Weight | around 1Ton |

Packaging Details | The normal package is plywooden box. If container is too tigher,we will use pe film for packing or pack it according to customers special request. |