Suzhou Polywell Engineering Plastics Co.,Ltd |

|

Verified Suppliers

|

|

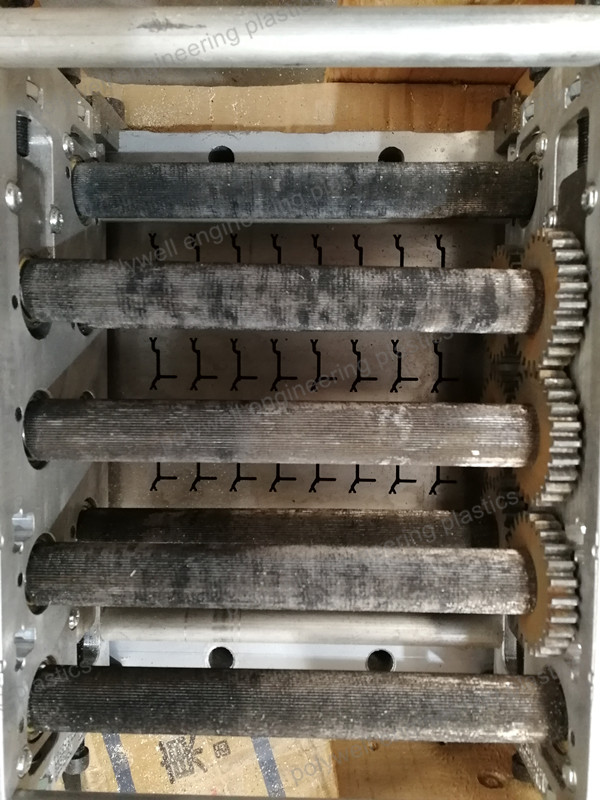

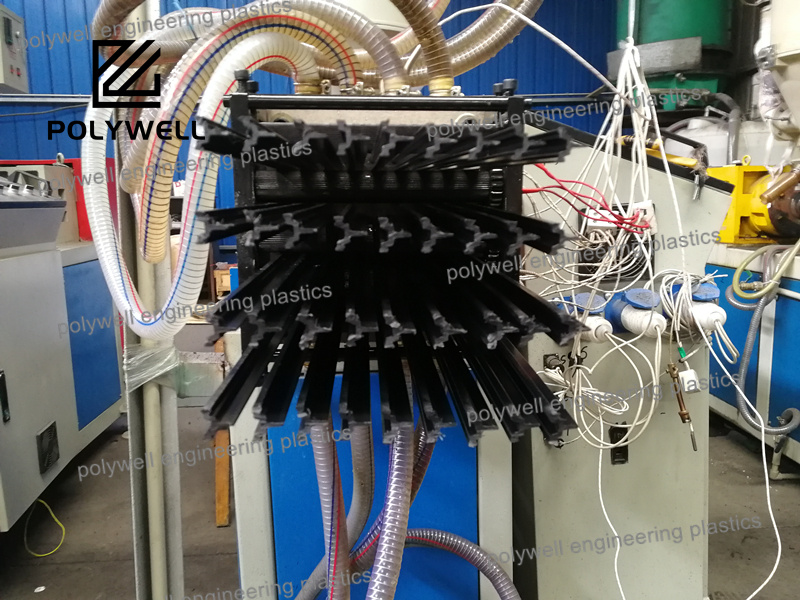

Plastic Moulding Dies are specialized production tools used to produce plastic parts via injection molding. The dies are made of highly durable materials, such as steel, and are designed to withstand the extreme temperatures and pressures of the molding process. The dies feature a cooling system that utilizes water to keep the parts from melting or warping, and a hot and cold runner system that allows for efficient plastic injection molding. The hardness of the cavity and core can be customized to a range of 48-52HRC and 55-60HRC respectively, while the size can be customized to meet the requirements of any application. Plastic Moulding Dies are capable of processing PA66GF25 granules, which are widely used in polyamide extrusion and nylon extrusion molding, making them ideal for many polyamide molding applications.

Polywell's PW-C extrusion molds are developed to meet the needs of polyamide extrusion. These molds are made with the highest quality standards of HASCO Standard and come with a certification from SGS. Our molds have a tolerance of ±0.1mm, and we can customize the size according to customers' requirements. We also provide different types of hot and cold runners to meet the needs of various molding applications.

The minimum order quantity for our molds is one set, and the price is negotiable. All molds are carefully packaged in a plywood case and delivered within 28-35 working days. Payment terms are 50% T/T before production and 50% T/T before delivery. We can provide up to 50 sets per month of our molds for customers.

Customized Plastic Moulding Dies for Polywell

Brand Name: Polywell

Model Number: PW-I24

Place of Origin: China

Certification: SGS

Minimum Order Quantity: 1 set

Price: Negotiation

Packaging Details: Plywood Case

Delivery Time: 28-35 Working Days

Payment Terms: 50% T/T before production, 50% T/T before delivery

Supply Ability: 50 Sets per Month

Size: Customized

Application: Mold Used In Polyamide Profiles Extruding Machine

MOQ: 1 Set

Tolerance: ±0.1mm

Plastic Processed: PA66GF25 Granules

Keywords: Plastic extrusion mold, nylon extrusion mold, polyamide extrusion mold

We provide technical support and service for plastic moulding dies. Our experienced professionals are available 24/7 to help you with any of your molding needs. We provide a wide range of services to ensure that your molding project is successful and cost-effective.

If you have any questions or need more information about our technical support and service for plastic moulding dies, please do not hesitate to contact us.

Packaging and Shipping for Plastic Moulding Dies.

The packaging of the Plastic Moulding Dies is done with great care and caution. We use high-quality corrugated cardboard boxes that are designed to protect the product from any form of damages during transit. The boxes are carefully sealed and secured with bubble wrap. The box is also labelled with the product details and other relevant information.

We use reliable courier services to ensure that the Plastic Moulding Dies is shipped safely and in a timely manner. The courier services take into account the product size and weight to determine the most cost-effective way to deliver the product. The tracking information is provided so that the customer can track the progress of their order.