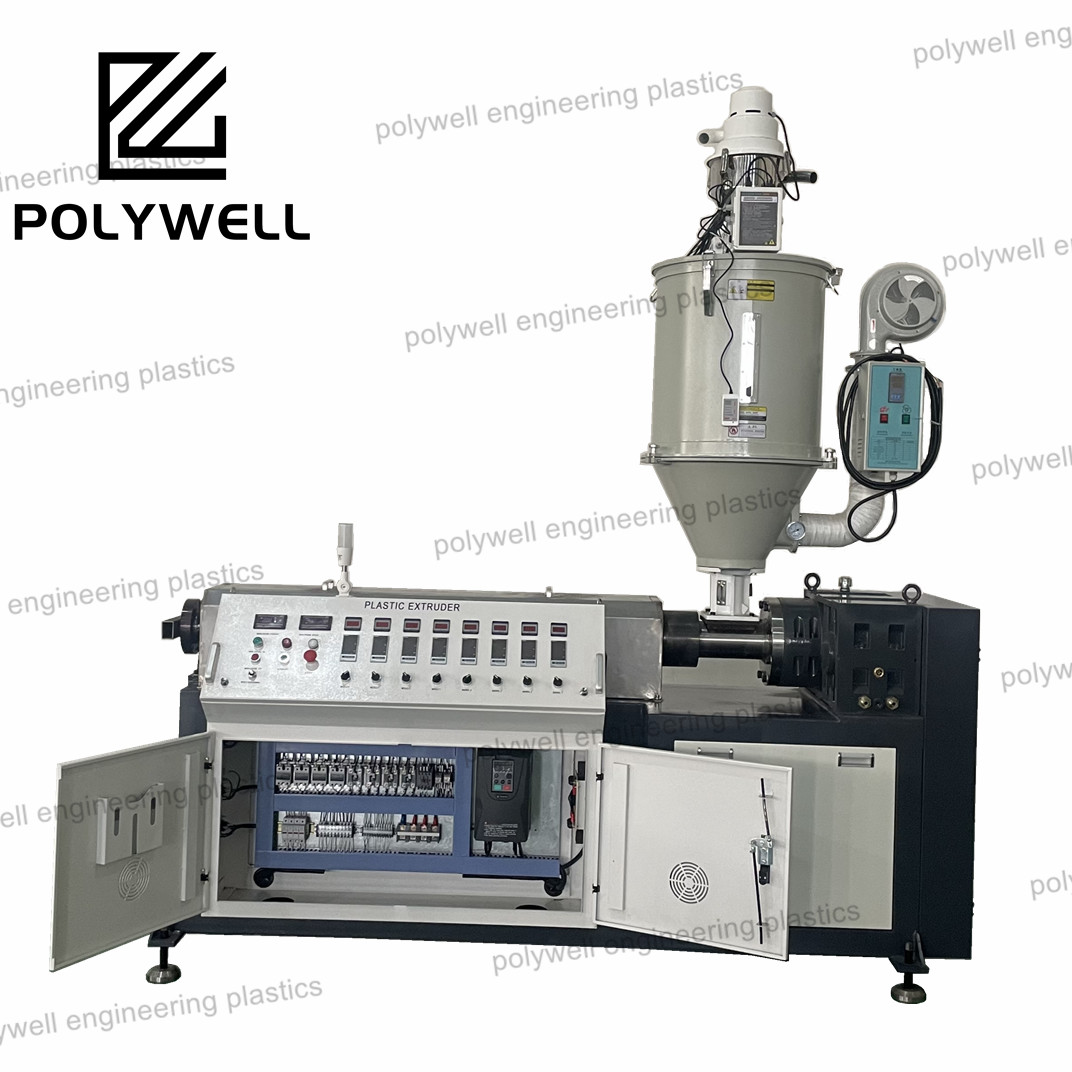

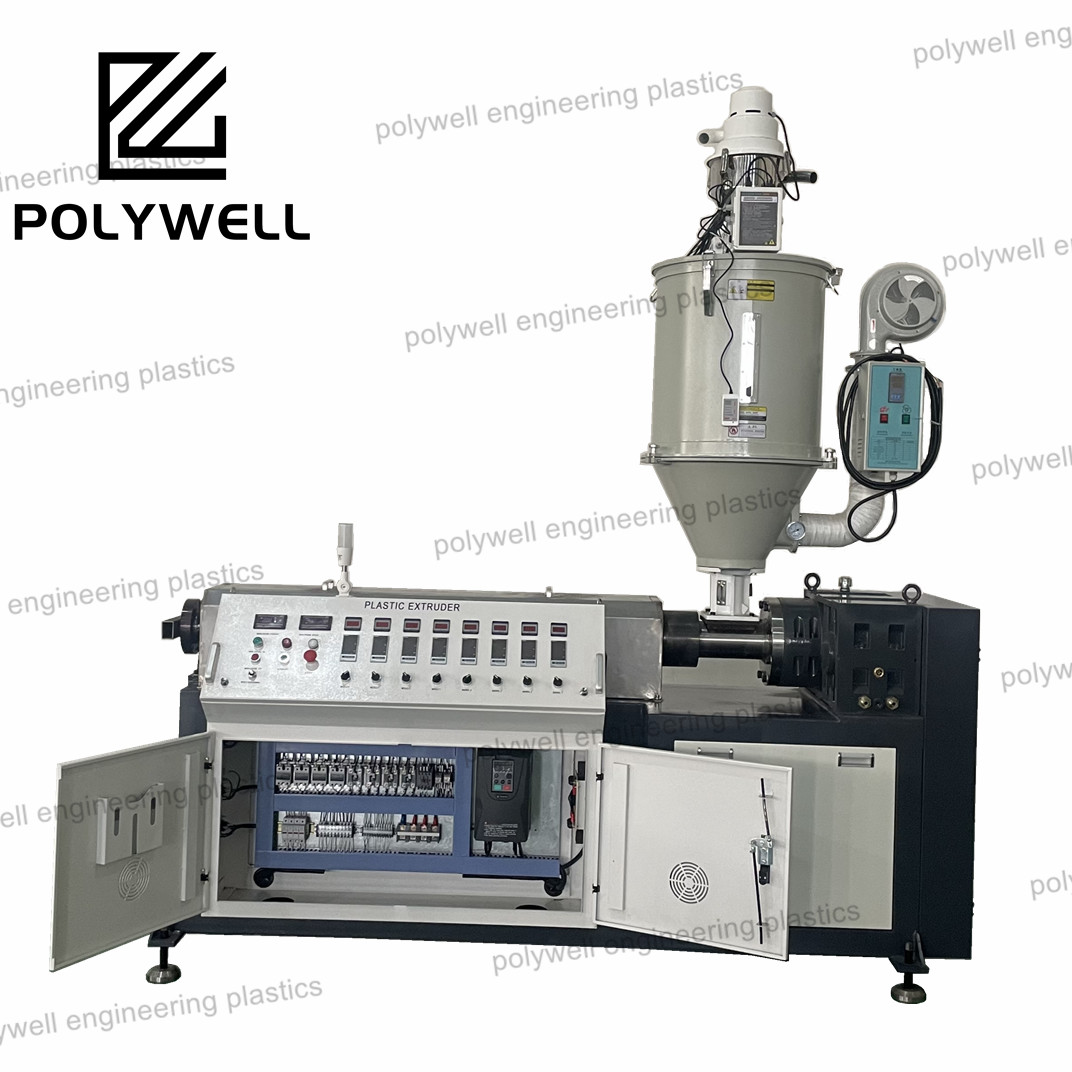

Polyamide Thermal Strip Processing Process

PA66GF25 granules are dired and get into the machine barrel through

the hopper. The granules are in rotary contact with the machine

screw, and move towards the mold with the rotation of the screw.

As the gap of machine screw and barrel is small, the granules are

heated in the gap under the process of moving forward. They are

plasticizied to nylon molten state through the high temperature of

the electric heating ring body. The molten state of nylon is

diverted and shaped after entering the mold, and finally extruded

into heat insulation strips.

Machine Parameters

| Material | PA66GF25 |

| Production Speed | 8-14 cm/min |

| Max Output | 60-80 kg/h |

| Power | 380V,50Hz or customized |

| Water | Tap water or well water |

Application of polyamide strip

Automatic PA profiles extruding machine is for the production of

polyamide thermal break profiles, which used in aluminum windows

and doors.

Many customer use thermal break aluminum profile to do windows and doors to keep the

heat from being affected by cold air, then make use of energy

saving.

Our advantage

We provide high quality PA profiles extruding machine along with

various molds and raw material-PA66GF25 granules, and also the

subsequent technical assistance. This machine includes raw material

auto feeding machine, hopper dryer, main engine, frequency

converter and gearbox.

Our Service

Before

1. Introduce products in detail

2. Recommend suitable solutions

3. Provide with reference information

During manufacturing

1. Provide with layout and engineering conditions

2. Inform the processing status

3. Offer related documents

After Sales

1. Provide installation, commissioning and training

2. Offer spare parts

3. Provide with necessary technical support

Production Time

28-35 working days after receiving the deposit.

Payment

50% T/T before production, 50% T/T before shipment.

Our Factory

Please feel free to contact us if you have any questions.

Lydia

Tel: +86 15601568506 (WhatsApp)

Email: lydia@szpolywell.cn

Address: Yangshe Town, Zhangjiagang City, Jiangsu Province, China.