Xi'An LIB Environmental Simulation Industry |

|

Verified Suppliers

|

|

Description

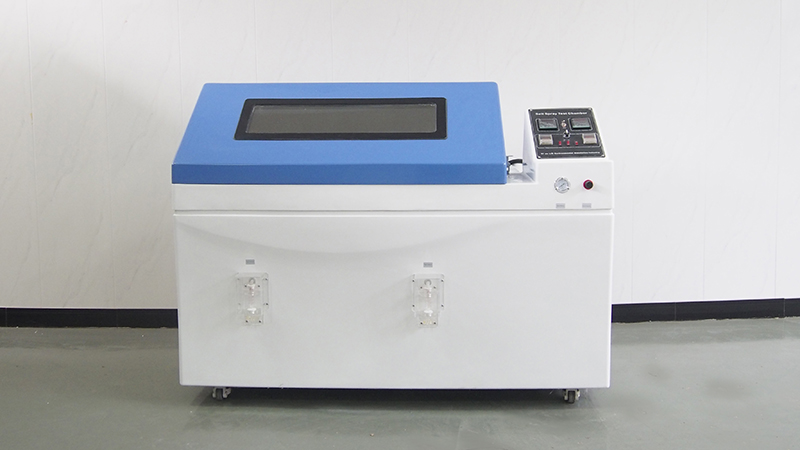

ASTM B117 Salt Fog Test Corrosion Chamber is mainly used for surface treatment of various materials, including coatings, electroplating, inorganic and surface films, and anodizing. After anti-corrosion treatment such as anti-rust oil, test the corrosion resistance of its products.

| Name | ASTM B117 Salt Fog Test Corrosion Chamber |

| Model | S-250 |

| Internal dimensions | 640*1000*500(mm) |

| Overall dimensions | 810*1800*1180(mm) |

| Temperature range | Ambient ~60℃ |

| Humidity range | 95% ~ 98% RH |

| Temperature fluctuations | +/- 0.5 ℃ |

| Temperature deviation: | +/- 2.0 ℃ |

| Test time | 1~999 hours, settable |

| Spray deposition | 1~2ml / 80cm2 · h |

| Spray type | Continuous / Periodic |

| Temperature Controller | LED display, P.I.D+S.S.R. microcomputer integrated controller |

| Temperature sensor | PT100Ω / MV A-class |

| Salt fog collected | Fog collector and fog measure cylinder |

| salt water filtration | Salt water filter near the suction tubes( Avoid the nozzle blockage) |

| Salt water preheating | Saturated air barrel |

| Spraying system | Atomizer tower and Spray nozzles (Fog is more fine and uniform distribution) |

| Interior /Exterior material | Glass fiber reinforced plastics |

| Standard configuration | Sample bracket / sample holder / spray nozzle / Fog collectors / measure cylinder |

| safety device | over-temperature protection, water shortage protection, over current protection, earth leakage protection |

| Sealing | Hydrostatic hood seal |

| Standard | ISO 3768/3769/3770, DIN50021-75, ASTM B-117, JIS H8502, IEC 68-2-11,IEC68-2-52, MIL-STD-750, ISO 9227 |

| Power Supply | 220V 50HZ |

| |

Salt Spray Device | Material |

| |

| Test Area | Observation Window |

Features

1. corrosion test chamber has an automatic/manual water adding system, which can automatically replenish the water level when the water level is insufficient, and the test is not interrupted.

2. The temperature controller uses digital display, and the PID control error is ±01.℃;

3. salt corrosion chamber,Double over-temperature protection, warning of insufficient water level to ensure safe use.

4. The laboratory adopts the direct heating method of steam, the heating speed is fast and uniform, and the standby time is reduced.

5. Salt Fog chamber,The precision glass nozzle is sprayed with adjustable mist, and the conical disperser of the spray tower of the mist volume is evenly scattered and diffused, and naturally falls on the test card, and ensures that no crystalline salt is blocked.

The ASTM B117 cycles include

Step 1: 35°C salt spray

Step 2: Go back to Step 1

Conditions for the salt spray test chamber to be used for ASTM B117 testing:

Salt spray deposition rate measured with a 100mm diameter funnel: 1–2 ml/hour;

Recommended spray pressure: 8psi;

Recommended solution flow: 1100 liters, 0.6 liters/hour; 600 liters, 0.5 liters/hour

|  |