Xi'An LIB Environmental Simulation Industry |

|

Verified Suppliers

|

|

Vehicle Testing Dust Tight Artificial Climate Chamber Talcum Powder Test

Vehicle Testing Dust Tight Artificial Climate Chamber Talcum Powder Test simulating the destructive effect of natural sand,dust and wind climate on products, suitable for testing the shell sealing performance of products.

Dust Proof Climatic Simulation Chamber provide environments to test exposure of automotive and electronic components to concentrated levels of dust to validate seal integrity.

Vehicle Testing Dust Tight Artificial Climate Chamber Talcum Powder Test is applied to test the performance of electronic & electrical products, automotive, motorcycle parts, seal the pieces in the sand and dust environment using, storage, transportation, etc.

| Model | DI-1500 | |||

| Internal dimensions (mm) | 1000*1500*1000 | |||

| Overall dimensions (mm) | 1250*1900*1960 | |||

| Temperature range | Ambient to +50℃ | |||

| Relative Humidity | <30%RH | |||

| Normal wire diameter | 50um | |||

| Normal width of a gap between wire | 75um | |||

| The Talcum powder amount | 2kg ~ 4kg/m3 | |||

| Fight time | 0 ~ 99H59M | |||

| Fan cycle time | 0 ~ 99H59M | |||

| Specimen power outlet | Dust-proof socket AC220V 16A | |||

| Controller | programmable color display touch screen controller | |||

| PC Link, R-232 interface | ||||

| Vacuum system | Equipped with a pressure gauge, air filter, pressure regulator, connecting tube | |||

| Circulating fan | Enclosed alloy low-noise motor, multi-vane centrifugal fan | |||

| Heating system | Independent Nichrome electronic heating system | |||

| Exterior material | Steel Plate with protective coating | |||

| Interior material | SUS304 stainless steel | |||

| Safety System | Electric leakage, short circuit, Over-temperature, motor overheating Over-current protection/ Power failure memory function for controller | |||

| Power supply | 380V 50HZ | |||

| Standard | IEC60529,ISO20653 | |||

Test Area & Shelf

Interior of Chamber is SUS304 stainless steel.

A stainless steel shelf for placing test specimens

Standard load of shelf is 50kg

Normal wire diameter is 50 um.

Normal width of a gap between wires is 75um.

Built-in power interface for test specimen

Test chamber internal illumination

Vacuum system for specimen

Control Panel

Programmable color touch display controller

99 programs 99 sections

R-232 interface

PC Link with software

Show total process time on controller.

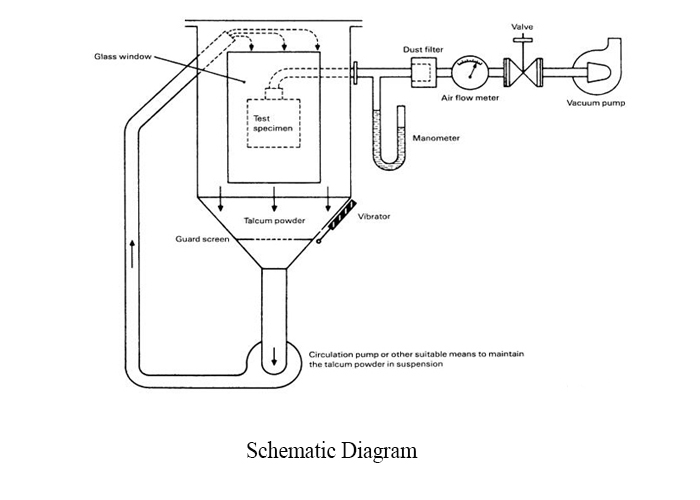

Dust Circulation

During test, dust is blown in test area by motor and blower, and then fall in funnel, and re-cycle blowing by circulating pump to achieve dust circulation.

Bottom of chamber is fitted with blower, vacuum pump, motor.

Dust collection section is located on bottom of test chamber.

Vacuum System for Specimen

Bottom of dust chamber is fitted with vacuum pump, a pressure gauge, air filter, pressure regulator, connecting tube which one side to connect pump, one side connect to test specimen.

Adjust vacuum value on control panel.

Viewing Window

Large viewing window with wiper

Can observe samples during testing

Safety Protection

Earth leakage protection,

Short circuit

Over-temperature protection

Motor overheating protection

Over-current protection

Power failure memory function for controller

3 Years Warranty, Lifelong Follow-up Services.

Training how to install and operate the machine.

Training how to maintain the machine.

Response within 24 hours once got questions from customers.

Send spare parts within 2 days after got notice.

Engineers available to service machines overseas to install and commissioning.