ZHANGJIAGANG FLAME MACHINERY CO.,LTD. |

|

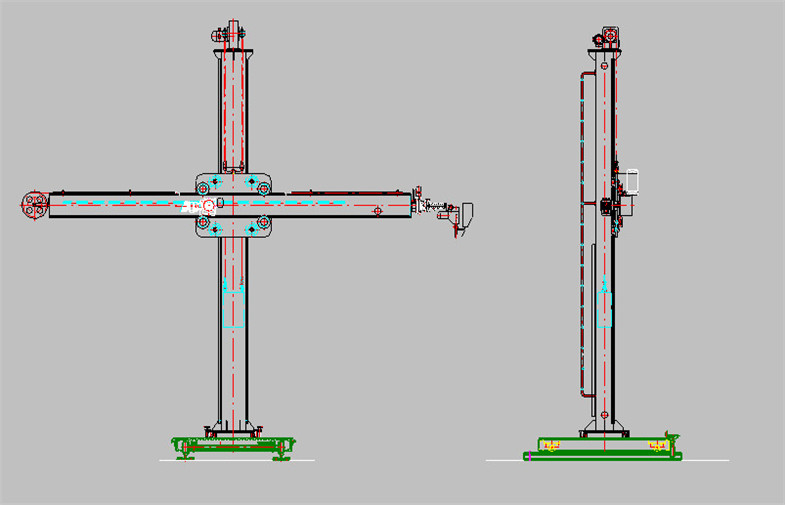

Column and Boom Welding Manipulator with Manual Rotation , Light duty , American Lincoln or Miller Welding System

Quick Details

column and boom welding machine of Introduction:

Welding column&Boom Manipulators of Guoheng stands out not only for innovation in design and quality of

manufacture, but also for reliability and robustness. It can realize automatic welding incorporate with SAW, MAG

and TIG welding systems, and extensively applied in pressure vessel, metallurgy, power, chemical industry, wind

tower, piping system and others lines. According to boom end load capacity, it is divided into light duty (LHQ),

medium duty (LHZ), heavy duty (LHW) and ultra heavy duty (HCJ).Below are the main parameters of our light

duty welding column&boom manipulator. We also provide tailor made welding column&boom manipulators

according to your special requirements.

2. Main Parameters

Model | LHQ1*1 | LHQ2*2 | LHQ3*3 | LHQ4*4 | |

Column stroke mm | 1000 | 2000 | 3000 | 4000 | |

Boom stroke mm | 1000 | 2000 | 3000 | 4000 | |

Boom lift speed mm/min | 1000 | ||||

Boom travel speed mm/min | 120—1200 | ||||

Max boom end load KG | 80 | ||||

Boom travel transmission | Gear and rack couple | ||||

Boom lift transmission | Chain and sprocket couple | ||||

Motorized slider unit mm | UP and DOWN range | 100 | |||

LEFT and RIGHT range | 100 | ||||

Min distance between boom lower surface and rail surface | 740 (moving and rotation) | ||||

690 (stationary and rotation) | |||||

Column rotation | Manual rotation then locked by screw | ||||

Boogie travel speed mm/min | Manual push then locked by screw | ||||

Boogie inner rail span mm | 1000 | ||||

Power supply | 380V 50HZ 3P or tailor made | ||||

Above are our standard models and parameters, and it can be designed and manufactured on request. | |||||

* We reserve the right to alter specifications without prior notice.

3. Main features

The standard models of our welding column&boom manipulators have the following features:

Optional features:

4. Supply range

5. Reference drawing