Tianjin Ironstar industry co,.Ltd |

|

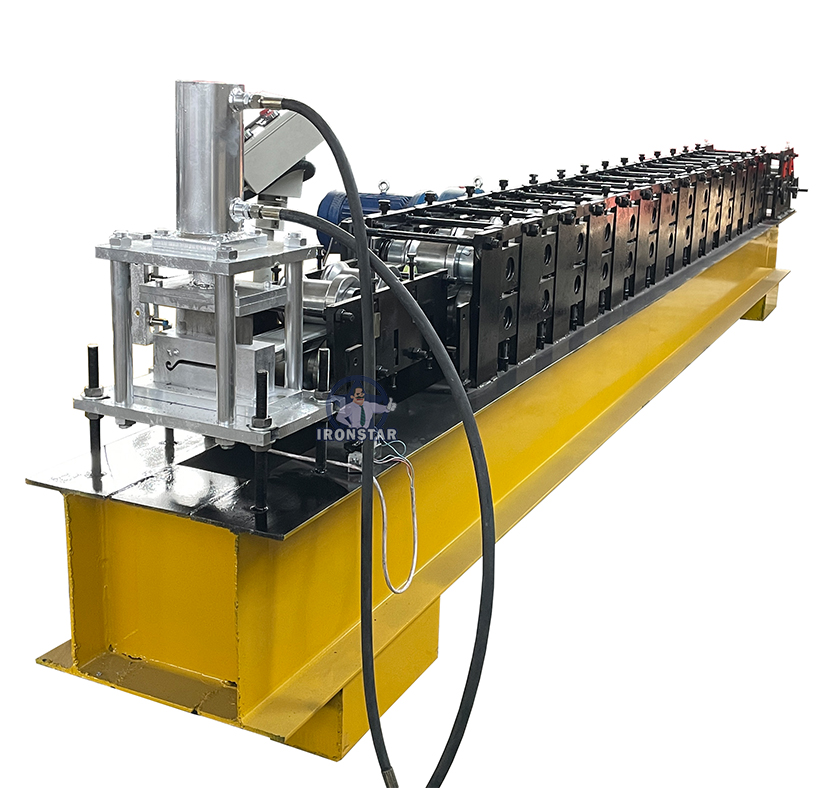

Customized 0.8-1.2mm Metal Sheet Roller Steel Bottom Strips Of Shutter Door Roll Forming Machine

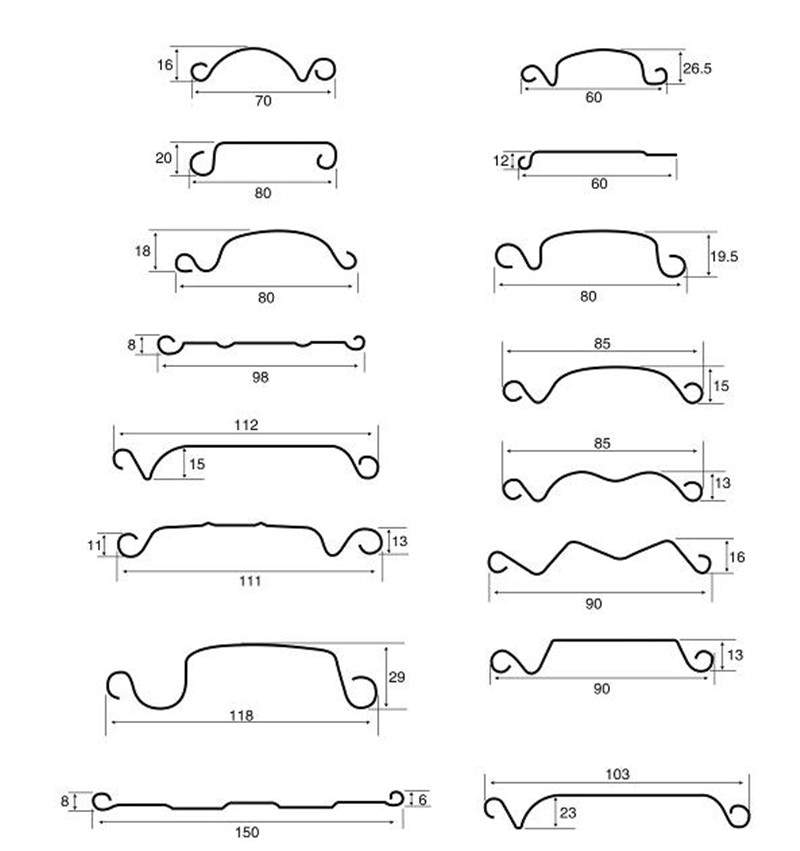

Shutter door roll forming machine popular sell in many countries, common shutter door rolling thickness from 0.7-1.2 mm, material use PPGI or Galvanized steel material

We sell lots of such machine to India, Thailand, Russia, Algeria, Qatar, Morocco, Saudi Arabic, Oman etc, Size can customize can your need size

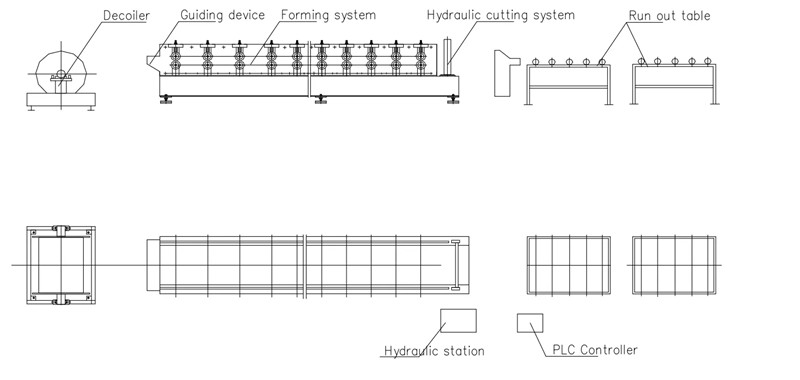

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

NO | Type | Specification | |

1 | Raw material | Type | Galvanized steel |

| Feeding width | As customer' drawing | ||

| Thickness | 0.7-1 mm | ||

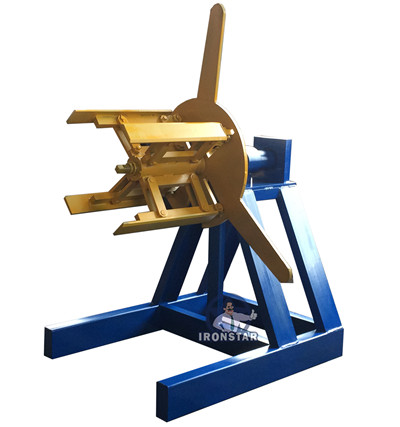

2 | Decoiler | Operation | Manual |

| Weight apacity | 3 Tons | ||

3 | Main body | Roller station | 14 rows |

| Diameter of shaft | 55 mm | ||

| Shaft material | 45# with 0.05mm chrome | ||

| Roller material | 45# with 0.05mm chrome | ||

| Frame | Steel plate welding | ||

| Frame thickness | 16 mm | ||

| Machine size | About 4.5*0.8*1 m | ||

| Machine weight | About 1.5 tons | ||

| Machine color | As customer need | ||

| Operation | Hydraulic automatic | ||

| Working speed | Common speed 8-20 m/min | ||

| 4 | Cutter | Hardness | 50-65 HRC |

| Cutting tolerance | ± 1mm | ||

| Material | Cr 12 | ||

| Operate | Hydraulic cutting | ||

| 5 | Power | Driving way | Chain 1 inch |

| Main motor | 4 KW | ||

| Pump motor for cutter | 3 KW | ||

| Voltage | 380V/50HZ, 3 phase or ass customer' request | ||

6 | Control box | Electric box | PLC control system, inventer |

| Screen | Touchable screen | ||

| PLC brand | Delta made in Taiwan | ||

| Inverter brand | Delta made in Taiwan or SAJ | ||

| Language | Chinese and English or as customer' request | ||

| 7 | Stacker | Operation | Manual |

| Length | 2-3 m | ||

It is used to stand the steel coil and uncoil, keep them work stably

Loading capacity: 3 tons

Coil inner size: 470-530 mm

Work type: Manual operation

Color: As customer' request

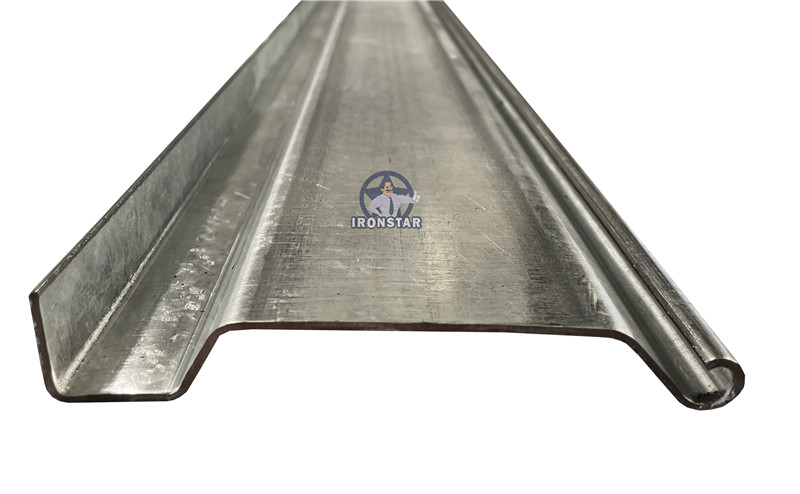

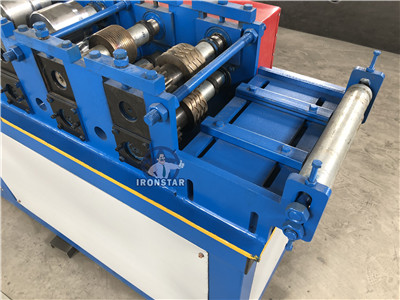

Roller material: 45# steel with 0.05mm chrome

roller surfaces polish, hard plating dealing

Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12, quenching treatment

Insert raw material (steel plate) through the beach to manufacture and process

It can guarantee coil go straight and the out products neat, parallel

DETAL PLC control system

Target piece`s length is adjustable and digit

Two modes operate: automatic and manual type

Button press and screen touch operate, easy operate

Language: Chinese and English or as acustomer' need

Hydraulic oil into the hydraulic oil tank

Pump motor drives the cutter work

Motor Power: 3KW

Hydraulic oil: 46# Oil

add capacity: oil add 3/4 of box capacity

Oil pressure: 8-10 MPa

Length: Common 2-3 m

Operate : Manual work

Used to collect the finished pieces

Support roller to transmit pieces

Easy for panel take away by forklifts

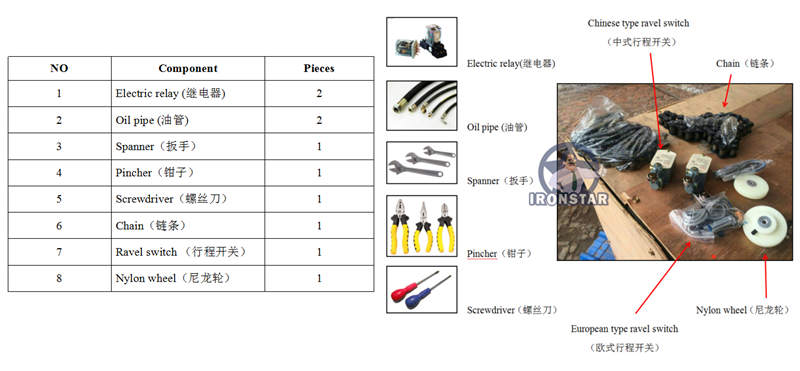

1). Packing method: Nude, seller should guarantee equipment will be moisture-proof, anti corrosive, and will not be damaged during transportation.

2). Payment Term: 30% of total contract value paid by T/T, last 70% paid by T/T after inspection by buyer in seller’s factory while before delivery.

3). Delivery Time: The seller guarantees the equipment will be ready for shipment within 40 working days after receipt of deposit from the buyer.

4). Service: We could send technician to your country to fix the machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 120 per day.

5). Warranty: 36 months During warranty, the replaceable parts are free, but the buyers need to pay for the shipping fee.

6). Package: One complete equipment needs a 20 feet container to hold.

Structural Support: The bottom rail acts as a foundation and support for the entire shutter door system. It helps distribute the weight of the door evenly and provides stability, ensuring proper alignment and operation of the door.

Durability and Strength: The bottom rail is designed to withstand the forces and stresses associated with the movement and operation of the shutter door. It is usually made of robust materials such as steel or aluminum to ensure durability and long-lasting performance.

Guide and Alignment: In some shutter door systems, the bottom rail incorporates guiding elements or tracks that help guide the door during operation. These tracks ensure smooth and precise movement of the door and help maintain proper alignment with the guide rails or tracks installed on the floor.

Weather Sealing: The bottom rail often includes weather seals or gaskets to provide a barrier against air infiltration, dust, and moisture. This helps improve energy efficiency, weatherproofing, and insulation properties of the shutter door system.

Security Enhancement: Some bottom rails may have additional features to enhance security. These can include built-in locks or mechanisms that allow the bottom rail to engage with the floor or threshold, providing added security and preventing unauthorized access.

Customization Options: Depending on the specific requirements and design preferences, the bottom rail of a shutter door can be customized. This includes options for different profiles, finishes, and sizes to accommodate various door configurations and aesthetic considerations.

The bottom rail of a shutter door is an integral component that contributes to the overall functionality, stability, and security of the door system. It works in conjunction with other components such as guide rails, slats or panels, and operating mechanisms to ensure smooth and reliable operation of the shutter door.

The shutter door bottom rail has various applications and plays a crucial role in the functionality and performance of the shutter door system. Here are some key applications of the shutter door bottom rail:

Structural Support: The bottom rail provides essential structural support to the entire shutter door system. It helps distribute the weight of the door evenly and ensures stability, allowing the door to operate smoothly and reliably.

Smooth Door Operation: The bottom rail, along with the guide rails or tracks in the floor, helps facilitate smooth and controlled movement of the shutter door. It acts as a guide, keeping the door aligned and preventing excessive swaying or misalignment during opening and closing.

Weather Sealing and Insulation: The bottom rail of a shutter door often incorporates weather seals or gaskets to provide a tight seal when the door is closed. This helps prevent drafts, air infiltration, moisture, dust, and other external elements from entering the space, improving energy efficiency and creating a more comfortable environment.

Security Enhancement: Some bottom rails are designed with additional security features to enhance the overall security of the shutter door system. This can include integrated locks or mechanisms that engage with the floor or threshold, providing added resistance against forced entry and unauthorized access.

Noise Reduction: The bottom rail, when properly designed and installed, can help minimize noise transmission through the shutter door. It acts as a barrier, reducing the transfer of sound vibrations between the door and the floor, thereby contributing to a quieter indoor environment.

Customization and Aesthetics: The bottom rail can be customized to match the specific design requirements and aesthetic preferences of the shutter door system. It can be manufactured in different profiles, finishes, and sizes to complement the overall appearance and architectural style of the door.

Overall, the shutter door bottom rail is a critical component that ensures the structural integrity, smooth operation, weather sealing, security, and customization of the shutter door system. Its application spans various sectors, including commercial buildings, industrial facilities, residential properties, and other spaces where shutter doors are utilized for security, privacy, and environmental control.

Shutter door bottom rail roll forming machine

Bottom rail roll forming machine for shutter doors

Roll forming machine for bottom rails of shutter doors

Shutter door bottom rail profile roll forming machine

Bottom rail manufacturing machine for shutter doors

Shutter door bottom rail forming machine

Roll former for shutter door bottom rails

Shutter door bottom rail production line

Industrial roll forming machine for bottom rails of shutter doors

Automatic roll forming machine for shutter door bottom rails

Custom bottom rail roll forming machine

Bottom rail roll forming machine suppliers

Bottom rail roll forming machine manufacturers

Rolling shutter machine

Shutter door machine

Roll forming machine for rolling shutters

Shutter slat machine

Automatic rolling shutter machine

Industrial rolling shutter machine

Rolling shutter manufacturing machine

Roll forming machine for shutter doors

Shutter profile machine

Shutter making machine

Shutter strip machine

Shutter roll forming machine

Custom rolling shutter machine

Rolling shutter machine suppliers

Rolling shutter machine manufacturers

Rolling shutter strip making machine

Shutter slat roll forming machine

Shutter strip roll forming machine

Rolling shutter profile machine

Roll forming machine for shutter strips

Shutter slat manufacturing machine

Industrial rolling shutter strip machine

Automatic rolling shutter strip machine

Shutter strip production line

Shutter slat roll former

Rolling shutter strip forming machine

Shutter strip fabrication machine

Custom rolling shutter strip making machine

Rolling shutter strip machine suppliers

Rolling shutter strip machine manufacturers