Jiangsu Lebron Machinery Technology Co., Ltd. |

|

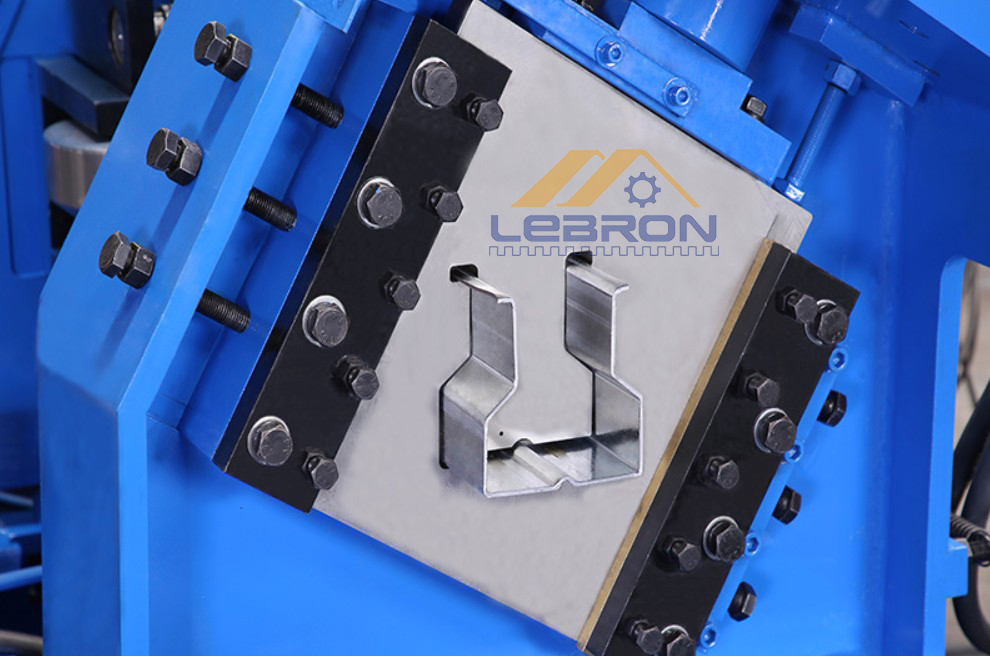

1. Description of Storage Rack Roll Forming Machine

Storage Rack Roll Forming Machine could be used to make storage racks in batch fully automatic. The thickness could be from 2.0 to 3.5 mm. Different from the medium-sized shelf, for filling the heavy work, there are some basic elements of the design of heavy goods racks to obey.

The storage rack roll forming machine includes hydraulic uncoiling, leveling, feeding, punching, forming, cutting, and discharging. The control adopts Siemens PLC, shelf column production line, touch screen input, high degree of automation, convenient operation, high production efficiency, and the production speed of the whole line can reach 40m/min.

This production line is highly automated, requiring only 1 to 2 people to operate. Adjustable profile specifications, a cold-formed production line, can produce a variety of specifications. Save production space and save production costs to the greatest extent for customers.

2. Technical Parameters Of Storage Rack Roll Forming Machine

| Suitable material: | Galvanized Steel, Cold Rolled Steel, Stainless Steel Coil |

| The thickness of Raw material | 2.0-3.0mm |

| Yield strength of the material | 340Mpa-550Mpa |

| Forming speed: | about 14~16m/min |

| Main motor power: | 30Kw |

| Hydraulic station power | 7.5Kw |

| Controlling system | Siemens PLC, Yaskawa Converter |

| Machines weight | about 12T |

| Machines size | about 8.0m×1.5m× 1.2m |

| Roller Material | GCr15 steel, coated with chrome, quenched heat treatment |

| Shaft Material | No.45 carbon wrought steel, precision machined, quenched |

| Shaft Diameter | Dia 95mm |

| Cutter blade and punch dies | Cr12MoV mold steel with quenched treatment |

| No. of Work Station | 30 stations |

| Frame | Outside is cast iron, the surface needed polish and paint. Inside is 60# forge and press metal |

3. Main Components Of Storage Rack Roll Forming Machine

| No. | Item | Quantity | Remark |

| 1 | 5-Ton Hydraulic Decoiler | 1 | As one complete part |

| 2 | Feeding Guide & Leveling device | 1 | |

| 3 | Roll Forming Unit | 1 | |

| 4 | Post Hydraulic Cutting Device | 1 | |

| 5 | Electric Control Cabinet | 1 | |

| 6 | Hydraulic Station | 2 | |

| 7 | Support Table | 2 |

4. After-Sale FAQ:

1). Q: How to acquire service support?

A: Lebron-Machinery is doing its best to provide timely and convenient service support for the customers, the contents of services including before-sale technical counseling, field installation, operate technical training, application solution training, and troubleshooting support, etc.

2). Q: After purchase Lebron-Machinery’s machine, what kind of training could Lebron-Machinery provide?

A: Lebron-Machinery will provide 7 days’ free training. The training place can be in Lebron-Machinery company or in places designated by the customer where installation takes place, this can all be predetermined by clients in the contract.

3). Q: What kind of warranty do Lebron-Machinery’s roll forming machines provide?

A: Except for the consumables, the whole machine has a one-year limited warranty.

4). Q: After buying Lebron-Machinery’s equipment, are there technicians in charge of supporting on-site installation?

A: Yes, if the equipment is directly sold from Lebron-Machinery, we will arrange experienced technicians to support the installation and collaboration when the machine arrives. If the device is sold by Lebron-Machinery’s distributors, we will authorize them to send experienced engineers to support the installation and collaboration when the machine arrives. Except the contract made other agreements for the installation.

5. Our Advantages

1). We are a factory with over 10 years experience in manufacturing Roll Forming Machines;

2). We have our own powerful research and development team

3). We have more than 15 technicians.

4). 5 engineers with more than 20 years of experience

5). We have an advanced Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. These advanced production equipment guarantee that the good quality of each part and the appearance of our machines;

6). Our machines have reached the International Inspection Standards;