Jiangsu Lebron Machinery Technology Co., Ltd. |

|

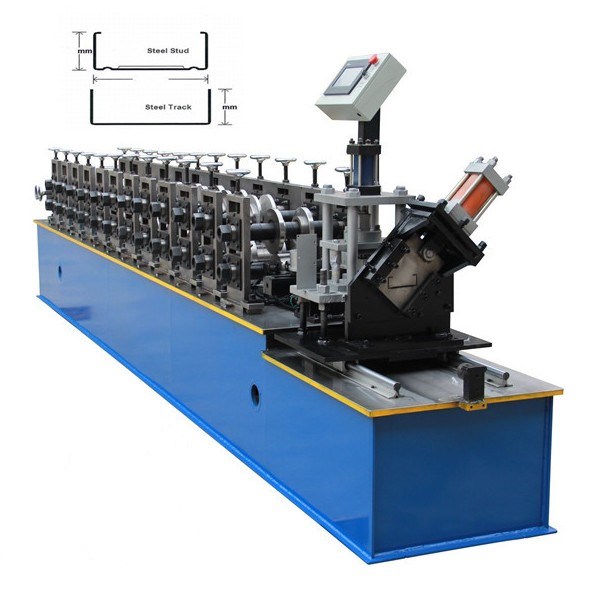

PLC control 5.5 kw stud and track roll forming machine new type full automatic

1. Description of stud and track roll forming machine

High Accuracy

Shaft material is No. 45 steel. Diameter is 55mm. The shafts are tooled by grinding machine 2 times. It’s strong and durable. Ensure product accuracy.

High Efficiency

Production speed: 20/min.

9600m per shift one day (8 hours).

Automatic & Easy Operate

Long service life

Roller material is high-grade No.45 forged steel, plated with hard chrome, processed by digital-controlled procession.

Mitsubishi PLC with the touchscreen. Friendly man-machine interaction. The system is simple to learn and easy to operate.

Automatic Operation: once you set quantity and length of the product, the machine will produce product automatically.

Simple to install and easy to maintain.

You only need to connect some tubes and wires in your factory. Video and manual will show you how to do.

Our experienced technicians can supply overseas service.

2. Major Technical Parameters of stud and track roll forming machine

| Suitable material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 0.5-0.6mm (235-345Mpa) |

| Material of roller | 45# steel being quenched treatment |

| Cutter blade& punching die material | Cr12 mould steel with quenched treatment, HRC58-60 |

| Power Requirement | Main motor power: 5.5Kw |

| Hydraulic station power: 5.5Kw | |

| Material of shaft | High quality 45# steel, with heat treatment. Roller grinder milling. |

| Forming speed | About 20m/min |

| Diameter of shaft for rollers | 55mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | About 15 stations for main rollers |

| Total weight of the machine | About 6500KGS |

| Machine's size | About 15m×1.7m× 1.4m |

3. Main components of stud and track roll forming machine

| Name | Quantity |

| Uncoiler | 1set |

| Coil sheet guiding device | 1set |

| Main roll forming system | 1set |

| Punching device | 1set |

| Cutting device | 1set |

| Hydraulic station | 1set |

| PLC control system | 1set |

| Support table | 1set |