SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

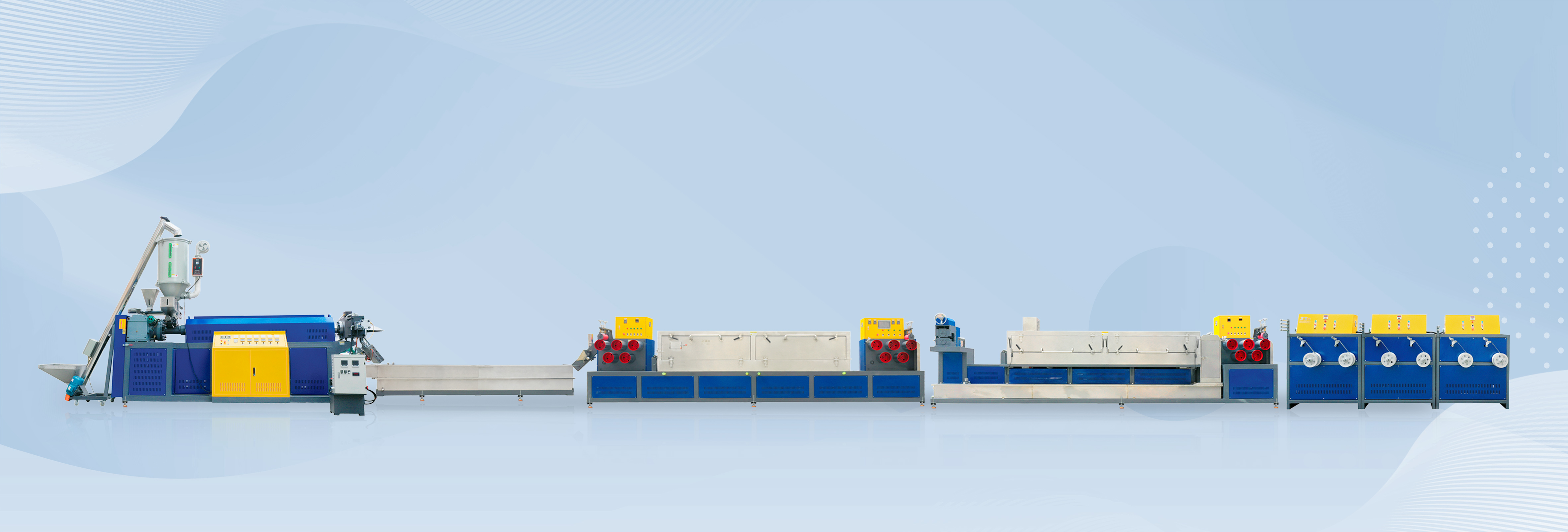

Plastic Polypropylene PP Strapping Production Line Extrusion Machine

Quick Details Of Plastic Polypropylene Strapping Band Extrusion Machine

Name: PP 1 to 4 strapping production line

Model number: JTPP-110

Applicable raw materials: New PP particles, PP recycled materials, PP crushed materials

Number of screws: 1 Screw

Number of extruded belts: 4

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200kg/h

Installation size: L38*W2.0*H4.0(m)

Configuration Of PP Strapping Production Line

| NO. | Name | QTY |

| 1 | Color Mixer | 1 set |

| 2 | Vacuum feeder or screw loader feeder (100% raw material use vacuum feeder machine;recycled material use screw loader feeder machine) customer choose one of it. | 1 set |

| 3 | Hopper dryer | 1 set |

| 4 | SJ single screw extruder | 1 set |

| 5 | High speed Screen exchanger device | 1 set |

| 6 | Molud | 1 set |

| 7 | Water cooling tank | 1 set |

| 8 | The first traction machine- 5 rollers | 1 set |

| 9 | The first Stretch forming oven | 1 set |

| 10 | The Second traction machine- 5 rollers | 1 set |

| 11 | The second Stretch forming oven | 1 set |

| 12 | The Third traction machine- 3 rollers | 1 set |

| 13 | Embossing machine | 1 set |

| 14 | The Winder machine | 1 set |

Features Of PP Strap Extrusion Line

1. Better tensile strength: the PET strap production line has the

tensile strength of the steel belt, and the ductility is good, and

the anti-impact performance is better. It is not easy to break, and

it can ensure the safety of product transportation.

2. Small extension: Although PET strap is one kind of plastics, its

extension of change is very small, its elongation is only 1/ 6 of

polypropylene, it can maintain tension force, after the packing

make the expansion no longer change.

3. Strong temperature resistance: the experiment proved that the

melting point of PET packing belt at about 260 ℃, can be used under

the environment of 120 ℃ for a long time not to distort,it has a

good stability.

4. Good economic benefit: the density of PET packaging belt is 1.30

~ 1.38 g/cm3, which is only 1/6 of the steel belt density (7.8

g/cm3), which is equivalent to the length of the 6-ton steel belt,

and the price of the same unit length is relatively low.

5. Environmentally friendly: the steel belt will rust due to

exposure to the air, and the rust is highly permeable to the

packaging. PET packing tape is beautiful and not rusted, but avoid

unnecessary worry. It can also be recycled.

6. Good flexibility and safe operation: the PET packing strip has

no sharp edge with steel belt, it will not scratch the package, and

it will not hurt the hand. You don’t need a special tool when you

cut it, even if it’s tight, it doesn’t hurt when you cut it.

7.High quality packaging ideal products: PET packaging with all

kinds of bright colors, shiny, high quality, the most ideal

packaging products of high-end packaging.

Turnkey Project Service About PP Strapping Machine

Pre-sale service:

1. To provide all the machines for the complete testing according

to customer's requirements.

2. To provide complete service for factory layout and other

information to help customer to build the factory.

After-service:

1. To provide raw material to the customer if you need.

2. Free installation and debugging and training until customers can

run the machines and make stably production.

3. Provide all kinds of product formula, technology

4. According to the customer's requirements, provide technical

guidance

5. Responsible for maintenance service, door to door service if

necessary.

6. Except one year quality guarantee,we will provide after-sell

service for all the life.

FAQ ABOUT PP BELT STRAPPING PRODUCTION LINE

Q1: Are you a trading company or a factory?

Q2: When can I get my machine after I paid?

Q3: How can I install my machine when it arrives?

A3: We will send our engineer to your side as soon as you get all

your machines ready , for testing and teaching your technicians how

to run the machines.

Q4: What's your guarantee or the warranty of the quality if we buy your machines?