SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

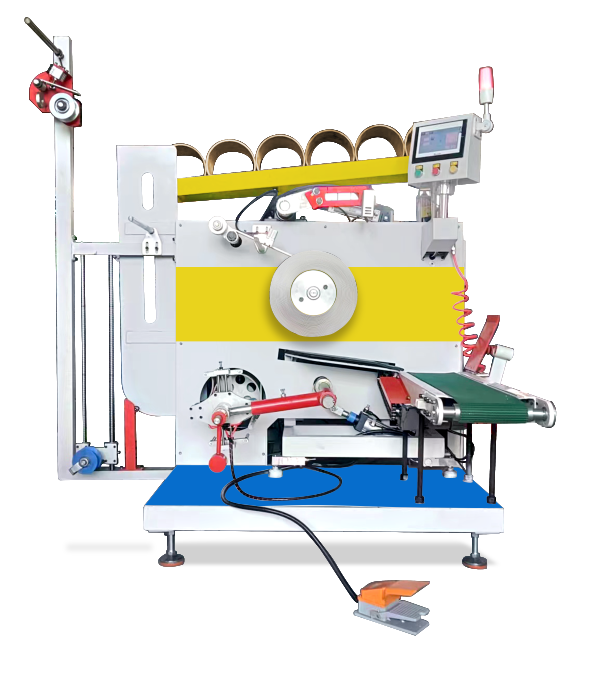

►The Strapping Band Winding Machine is an advanced, dual-servo

motor PP strap winder designed to package and transport goods

safely and securely. It is equipped with a touch screen control

that allows for easy and precise settings for an efficient and

high-quality strapping job. The machine is capable of winding paper

tubes with a diameter of 203mm and a length of 165~195mm.

Additionally, it is equipped with a moment mode and can handle

straps with a thickness of 0.4-1.2mm. It also has a no-gear-change

feature that offers an easy and convenient operation. This

state-of-the-art strapping band winding machine is an ideal choice

for a wide range of packing tape winder applications.

►Using condition: power single-phase 220V, air pressure 4-7kgf, plug

the air pipe(Φ8)in according to the marks on the equipment,connect

the electronic line(2.5 m2 +).Ventilate first, then electrify(When

turning off the machine in reverse order-first turn off the

electricity, then turn off the air pressure).

►use the servo motor to lay the cable, and wind up the PP STRAP with

the width of 7-19mm. Select the corresponding bandwidth through the

touch screen to wind up, and there is no need to manually replace

the transmission gear.

►After the winding is completed, the machine will stop

automatically, replace the paper tube, cut off the PP STRAP and

clamp the pieces to fix the STRAP head, and the winding operation

will be carried out automatically, and the whole process will be

completed automatically.

►The winding shaft uses the torque mode of servo motor, and the

torque during winding can be set through the touch screen, so that

the PP STRAP with different gram weight or width can be wound with

appropriate torque, so be best to minimize the bending deformation

of the PP STRAP after winding.

►After the winding is completed, the exiting packing belt will

automatically move to the storage belt conveyor. About 3 rolls can

be placed on the conveyor, and it can also be lengthened according

to the needs of customers.

| Product Name | Strapping Band Winding Machine |

|---|---|

Width | 9-32±0.5mm |

Thickness | 0.6-1.2mm±0.25mm |

Paper core diameter | Ø200*180mm(Negotiable) |

| No manual volume change is required | YES |

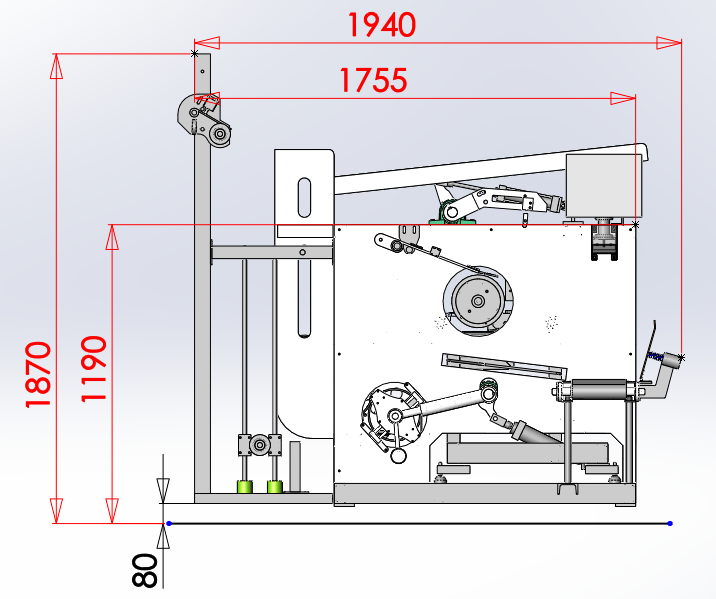

| Machine size | L1900*W1850*H1800mm |

| Power Consumption | 1.8KW |

| Speed | 220-350m/min |

| Using condition | Power Single-phase 220V |

| Automatic rewinding | YES |

| Automatic paper tube change | YES |

| Strap Thickness | 0.4-1.2mm |

| Keywords | Servo motor line automatic winding machine, Automatic winder, Servo winding machine |

The PP Strap Winder Dual-Servo Motor is a revolutionary product from Packing Tape Winder, designed to provide efficient, high-performance winding of PP straps for various applications. This full-automatic winder comes with model number JTPP/PET, and is produced in China. Its power consumption is 1.8KW and its speed is between 220-350m/min, making it an ideal choice for any high-speed packing or strapping application. The winder is equipped with a Xinjie PLC and a touch-screen to make operation easy and efficient. It also has adjustable strap thickness settings between 0.4-1.2mm, making it suitable for a wide range of strapping and packing applications. With its dual-servo motor technology, the PP Strap Winder provides reliable and efficient winding of PP straps, making it an ideal choice for any industrial or commercial strapping project.

Our Strapping Band Winding Machine is a PP strap full-automatic winder with the following features:

Our Strapping Band Winding Machine is powered by a Servo motor line

for an automatic winding machine. It is ideal for PP strapping and

other materials.