SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

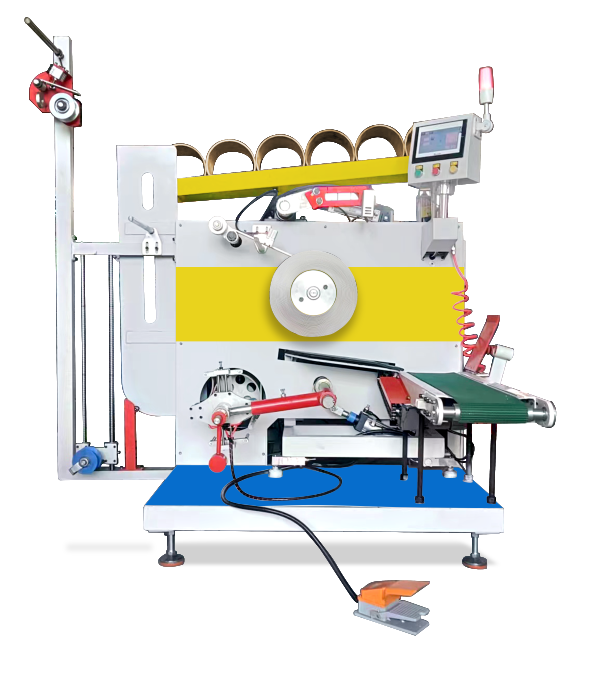

►After the winding is completed, the machine will stop automatically, replace the paper tube, cut off the PP STRAP and clamp the pieces to fix the STRAP head, and the winding operation will be carried out automatically, and the whole process will be completed automatically.

►Use the servo motor to lay the cable, and wind up the PP STRAP with the width of 7-19mm. Select the corresponding bandwidth through the touch screen to wind up, and there is no need to manually replace the transmission gear.

►The winding shaft uses the torque mode of servo motor, and the torque during winding can be set through the touch screen, so that the PP STRAP with different gram weight or width can be wound with appropriate torque, so be best to minimize the bending deformation of the PP STRAP after winding.

►After the winding is completed, the exiting packing belt will automatically move to the storage belt conveyor. About 3 rolls can be placed on the conveyor, and it can also be lengthened according to the needs of customers.

►Using condition: power single-phase 220V, air pressure 4-7kgf, plug the air pipe(Φ8)in according to the marks on the equipment,connect the electronic line(2.5 m2 +).Ventilate first, then electrify(When turning off the machine in reverse order-first turn off the electricity, then turn off the air pressure).

►The automatic winding machine completely replaces the manual, suitable for PP packing tape production wire coil, and PET plastic steel tape production equipment coil, winding neatly, beautiful and generous.

| Product Name | Automatic Winder |

|---|---|

| Model | PP Strap Full-automatic Winder |

| Product Type | Automatic Winding Machine |

| PLC | Xinjie |

| Touch Screen | Xinjie |

| Operation Mode | PLC Computer Touch Screen |

| Tension Range | 80-500kg |

Width | 5-18mm |

| Thickness | 0.4-1.2mm |

| Adjustable Tightness | YES |

| Auto Wrap PE Film | YES |

| Moment Mode | YES |

| No Manual Volume Change Required | YES |

| Air Pressure | 4-7kgf |

►The Strapping Band Winding Machine is a revolutionary product that has completely transformed the way packing and winding is done. With its advanced technology and user-friendly interface, it has become a must-have in the packaging industry. The machine is designed and manufactured by a leading brand in the industry, Automatic PP/ PET packing and winding machine, with the model number JTPP/PET, and has its origin in China.

Brand Name: Automatic PP/ PET packing and winding machine

Model Number: JTPP/PET

Place of Origin: CHINA

Servo motor wiring: YES

No need to change gears: YES

Automatic paper tube change: YES

Package Weight: 750kg

Servo motor: YES

We are proud to offer customized services for our Strapping Band Winding Machine. Our full-automatic winder, equipped with servo motor line, allows for automatic winding, making the process efficient and easy. Our machine also features servo motor wiring, eliminating the need to manually change gears. Additionally, our machine has the capability of automatic paper tube change, further streamlining the packing and winding process. Made in CHINA, our machine is of high quality and has a package weight of 750kg. Choose our Automatic winding machine for a hassle-free and efficient packing and winding experience.

The Strapping Band Winding Machine is a high-quality and efficient solution for winding and securing strapping bands. We are committed to providing excellent technical support and services to ensure that our customers get the most out of their investment.

Our team of highly trained technicians is available to assist with any technical issues or questions that may arise with the Strapping Band Winding Machine. We offer remote support, on-site visits, and troubleshooting services to ensure that your machine is running smoothly and efficiently.

We provide comprehensive installation services to ensure that the Strapping Band Winding Machine is set up correctly and ready for use. Our technicians will also provide training to your staff on how to operate and maintain the machine for optimal performance and longevity.

In the event of a malfunction or breakdown, our team is equipped to provide prompt repairs and maintenance services to minimize downtime and keep your production running smoothly. We also offer regular maintenance packages to keep your Strapping Band Winding Machine in top condition.

We understand the importance of having reliable and high-quality spare parts and accessories for your Strapping Band Winding Machine. That's why we offer a wide range of genuine parts and accessories to ensure that your machine continues to operate at peak performance.

Our dedicated customer support team is available to answer any questions or concerns you may have regarding the Strapping Band Winding Machine. We strive to provide timely and helpful assistance to ensure that our customers are completely satisfied with their purchase.

Thank you for choosing our Strapping Band Winding Machine. We are committed to providing top-notch technical support and services to help you achieve your production goals.

Our Strapping Band Winding Machine is carefully packaged and shipped to ensure safe delivery to our customers. The following steps are taken to ensure the best possible packaging and shipping process: