SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

1.The extruder uses a special PET screw with unique parameter design. The screw has a unique separation and mixing effe ect to ensure the uniform plasticization of the raw materials. It has the advantages of large extrusion, good plasticization,high hardness, high wear resistance, etc.

2.The three-dimensional folding super !arge area filter device, the unfolded area of the filter screen is 30 times larger than tl the area of the traditional flat filter screen; the filter mesh can reach 80 meshes, and the unique screen changing device greatly reduces the screen changing time and improves work efficiency.

3.The rotating honeycomb dehumidification drying system is used to dry the raw materials.

4.The dew point of -50°C ensures that the moisture content of the raw materials is ≤50PPM, and has the effect of solid-pha ase polycondensation and viscosity increase.

stable, and the width and thickness fluctuations are much smaller than national standards;

5.The equipment adopts a unique double-stretching process, which has good rigidity and stable width, which improves the t tensile strength of the finished product.

6.High-precision components make the product quality Unique oven circulating heating system, internal reciprocating winding method, making full use of heat energy to

greatly r reduce power loss.

7.ToThe unique circulating cooling system and multiple sets of shaping guide rollers make the packing belt cooler and shrinl nk more fully, the product is more stable, and the size is more accurate.

8.ToThe five-roller traction system has stable traction, makes the equipment run smoothly, reduces the failure rate, and red duces the post-maintenance cost by 60%.

9.ToThe high-precision special embossing and pressing device, the pressure is adjustable, the embossing wheel can be sy ynchronized up and down, the embossing is clear and beautiful, and the product quality is comparable to that of Europe, America, Japan and South Korea.Constant force rewinding system, unique design paramet ters, in line with high output, excellent reeling effect, flat and beautiful sides on both sides.

10.The rewinding machine adopts double-station rewinding device, which is easy to operate and easy to change the reel.

11.It can be produced entirely with 100% bottle flakes, and the quality of the finished product can be compared with brand ne ew materials

| Parameter | Details |

|---|---|

| Automation | Automatic |

| Application | Sheet, Strap, Pipe, Packaging Band, Tape And Strap |

| Strap Width | 9-32mm |

| Total Power | 200KW |

| Strap Thickness | 0.4-1.2mm |

| Line Speed | 220-250m/min |

| Strap Tension | >1000kg |

| Equipment footprint | 50*2.0*8.0M |

| Paper core specification | ¢ 406*150mm |

| Product Name | PET Strap Extrusion Line |

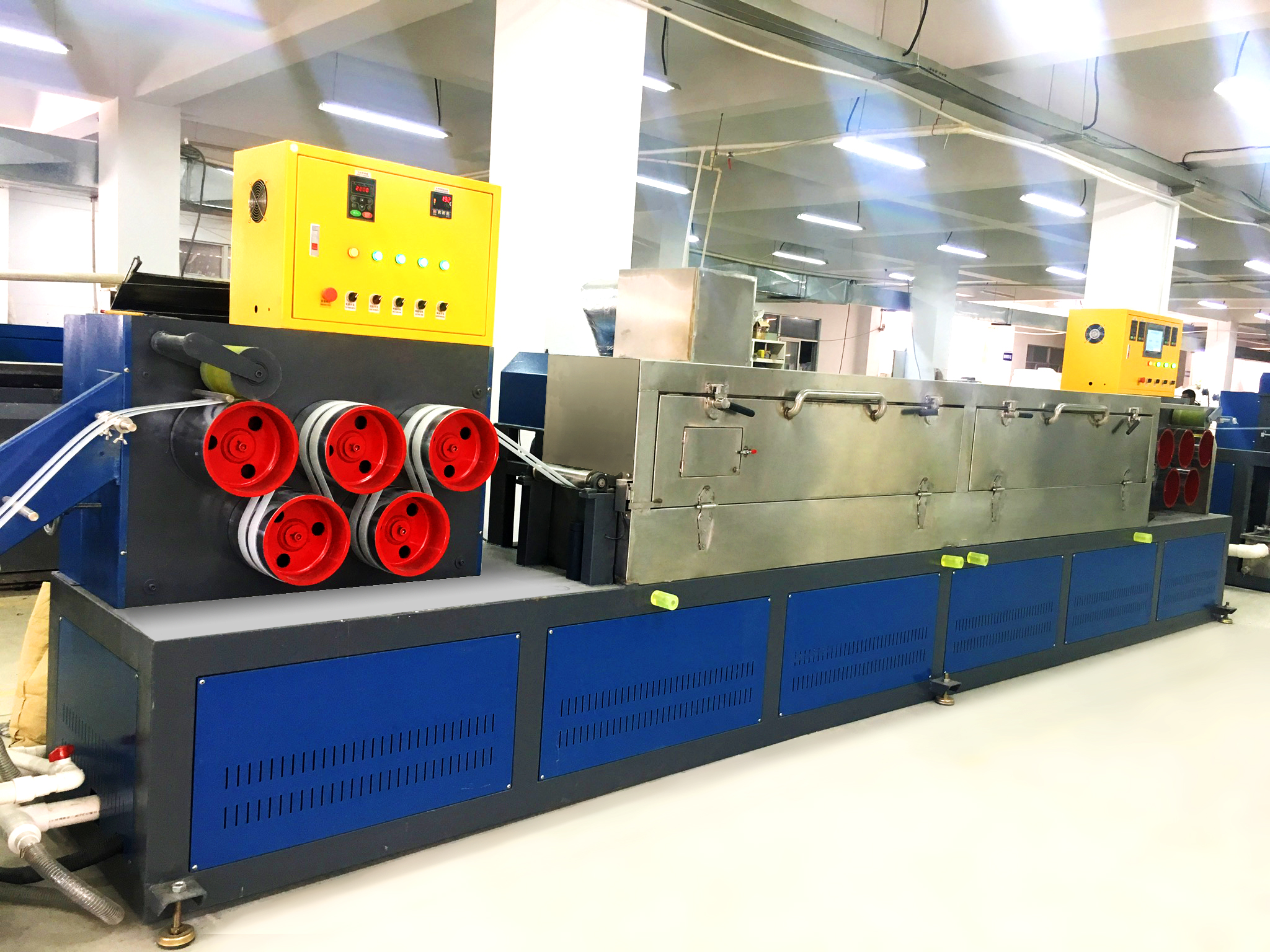

The JIATUO CHINA PET Strap Extrusion Line, model JTPET, is a high quality production line that is certified with CE, SGS, and ISO, and requires a minimum order quantity of 1 SET. It has a delivery time of 50-60 days, and comes with two double position winders. It is powered by 380/50Hz/220/60Hz three-phase power supply and has an equipment footprint of 55*2.0*8.0M.

The PET Strap Extrusion Line is suitable for use in producing sheet, strap, pipe, packaging band, tape and strap products. It is a reliable and robust production line that offers high performance and efficiency. The PET strap production line has a range of features that make it an ideal choice for many industries, including excellent quality control, precise control of the extrusion process, and a high degree of automation. It is also highly energy efficient, ensuring that production costs are kept to a minimum.

The PET Strap Extrusion Equipment from JIATUO CHINA is an ideal choice for businesses that require a reliable and efficient production line for PET strap and other products. With its robust design, high performance, and energy efficiency, it is the perfect solution for companies that want to produce high quality products quickly and efficiently.

PET Strap Extrusion Line

Brand Name: JIATUO CHINA

Model Number: JTPET

Place of Origin: CHINA

Certification: CE SGS ISO

Minimum Order Quantity: 1 SET

Delivery Time: 50-60 Days

Paper core specification: ¢ 406*150mm

Total Power: 200-250KW

Strap Width: 5-19mm

Equipment footprint:: 50*2.0*8.0M

Material: PET-110

Temperature controller and solid state relay: Taiwan Yangming, switch and other electrical appliances: Schneider.

As a new type of strapping product with strong tensile force and

corrosion resistance, PET strapping belt is gradually replacing

traditional stainless steel strapping products with overwhelming

advantages in performance and price. Therefore, the potential of

PET strapping production line as a small and medium-sized

investment is huge.It is widely used in steel, aluminum, chemical

fiber, cotton spinning, tobacco, paper, metal can making and other

industries.

We provide technical support and services for our PET Strap Extrusion Line, including:

Packaging and Shipping for PET Strap Extrusion Line

The PET Strap Extrusion Line will be packaged safely and securely in cardboard boxes or wooden crates to prevent damage during transit. Each box or crate will be clearly labeled with the customer's name, address, and shipment details.

The PET Strap Extrusion Line will be shipped by truck, train, or air freight, depending on the customer's needs and the size of the order. All shipping costs will be the responsibility of the customer.