Top Sensor Technology Co.Ltd |

|

Verified Suppliers

|

|

Model: DTS-01

Capacity: 0.1/0.2/0.3/0.5/1/2/3/5/10/20/30/50/100Nm

Precision: ±0.1; ±0.3; ±0.5%F.S

Output sensitivity: 1.0~1.5.0 mV/V, 4-20mA, 0-5/ 0-10Vdc

Features:

1, Torque sensor consists of strain gauge and integrated circuit with high precision and stable performance.

2, With excellent long term stability

3, With key connection on both end

4, 4000RPM at most

Technical specification:

| Working Temperature: | -10~+80 ℃ |

| Temperature compensated range: | room temperature ~+60 ℃ |

| Temperature effect on zero: | ±0.1 %F.S/10 ℃ |

| Excitation voltage : | 12 VDC |

| Insulted resistance: | 2000 MΩ/100VDC |

| Input resistance: | 700±10/350±10 Ω |

| Output resistance: | 700±5/350±5 Ω |

| Zero output: | 0~±1 %F.S |

| Safety overload: | 120 %F.S |

| Cable length: | 3 m |

Cable connection: | Red: Exc+ Black: Exc - Green: Signal + White: Signal- |

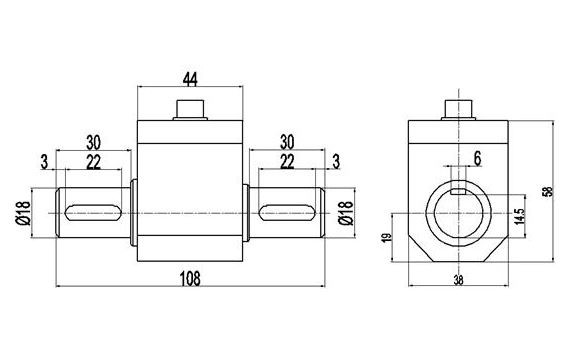

Dimension: mm

key groove dimension: LxDxW 22x3.5x6mm

1, Application Area

DTS series dynamic torque sensor is an accurate measuring device for torque and mechanical power consumption. Mainly applied in

1.1 Electromotor, Engine motor, internal-combustion engine and other rotating equipment.

1.2 Fan, water pump, torque wrench

1.3 Train, auto mobile, tractor, airplane, ship, mining machine

1.4 Water recycling system

1.5 Viscometer

1.6 Process industry

2, Installation requirement

2.1 Suitable for both vertical and horizontal installation

2.2 All loading equipment, torque sensor, power equipment should be installed on a solid platform to avoid excessive vibration. Otherwise, it may cause unstable reading, reduce accuracy or even damage torque sensor.

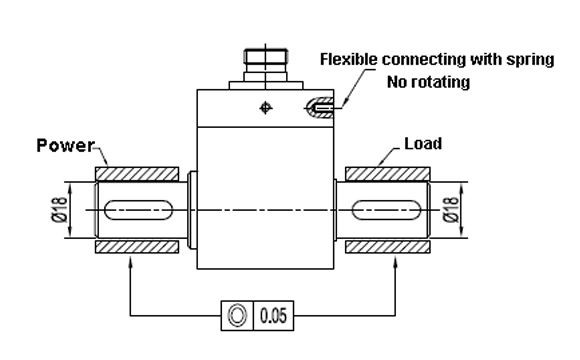

2.3 Use elastic pin coupling

2.4 Flexible fixing is recommended for fixing the middle part of torque sensor. Do not apply rigid fixing.

2.5 Concentricity tolerance of loading equipment, torque sensor, power equipment should be less than Φ0.05mm.

3, Installation steps

3.1 Confirm distance between power equipment and loading equipment based on shaft connection type and torque sensor length. Adjust the gap between the axil line (of power & loading equipment) and datum plane, make sure the coaxiality between them is less thanΦ0.03mm, then fix power & loading equipment on datum plane.

3.2 Install coupling on each shaft

3.3 Adjustment the distance between torque sensor and datum plane, make sure the coaxiality between their axil line and the axil line of power & loading equipment is less thanΦ0.03mm. Then fix torque sensor on datum plane.

3.4 Fix the coupling, installation finished.

4, Normal installation ways

4.1 When speed is less than 300RPM, no frequent clockwise and anti-clockwise rotating, some flexible object can be used to connect with torque sensor and prevent it from rotating.

4.2 When speed is higher than 300RPM, with frequent clockwise and anti-clockwise rotating, fixing plate on both front and back of torque sensor is necessary. Add 2-3 mm silicon rubber in the middle of torque sensor and fixing board with 15%-20% compression amount to prevent it from becoming rigid connection.