Shenzhen Guangya Automatic Machinery Ltd |

|

Verified Suppliers

|

|

Description

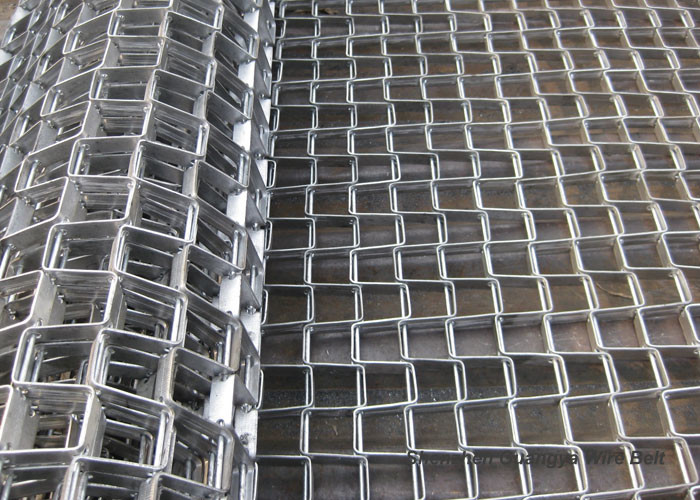

Great wall belt,also called honeycomb belt,flat wire belt,it is weaved by flat iron steel wire or sheet and round iron support shaft,belt is light,mesh space is big,smooth speration,running steady.can used in the washing,drying,cooling and heat treatment's conveyor line.

Features

Excellent strength to weight ratio but with maximum flexibility to

prevents belt from deforming under heavy loads.

High temperature resistance, non-slip, anti-corrosion, anti-rust,

resistant to acid and alkaline.

Complying with food safety standards .

Large opening area with good air circulation.

Side and center baffles can be added to the conveyor belt to

prevent the products from falling down to the ground.

Easy to clean, assemble and disassemble, save maintenance cost,

durable and long lifespan.

Applications

-- Conveyor machines

-- Frying facilities

-- Annealing furnaces

-- Refrigeration facilities

-- Cleaning machines

-- Drying ovens

-- Food transport

-- Baking

-- Cooling and freezing

-- Steaming and drying

The stainless steel mesh belt installation

Before sending inquiry ,the following wire mesh belt information need to be told:

material

| such as stainless steel 304,316,316L,310,430 and so on |

| datas | spiral wire diameter,string wire diameter,pitches of spiral wire,string wire,rod daimeter,width and length |

requriement

| such as working temperature,laoding weight |

| size of the belt | wide and length can be designed according to customer`s requriement. |

advantages |

anti-corrosion, anti-rust, resistant to acid and alkaline |

place of origin | Guangdong,China |

Here are some photos of this product:

The reasons for choosing us:

1.Excellent company background

Shenzhen guangya Wire Belt Co was founded in 2005 for production of stainless steel wire conveyor belt, plate belt, stainless steel roller chain, teflon belt and machinery transmission components. Being ISO and SGS certified company, we're well recognized for high quality and one stop purchase solution. Our products are widely used in medcine, chemical, printing and coating machinery industries. We have built up long term partnership with clients in both domestic and oversea countries for reliable quality products.

2.Quick Production line

We have a solid production team with over 12 years and each operator has been working in this industry for more than 5 years. At the same time, we have more than 50 existing moulds to use directly that means we can produce the specified product quickly.

3.Custom design

We have a professional engineering department for quick design upon

customer requirements.

4.Competitive price

We are running mass production model and have built up advanced

partnership with source material providers. We can save much cost

and provide very promotional offer to clients.

5.Best pre-sale and after-sales service

We have professional pre-sale and after-sales service team which

consist of many people and each has more than three years

experience. If you have any questions after you receive the cargo,

you can call us or send email all day.

Other FAQ

1.Q:How long will it take to produce and how long will it take to get the goods?

A:It takes 5-10 days for production in factory depends the total quantity. Each belt is custom made based customer side exact parameters.Generally speaking, you will receive the package within 30 days and if you have any logistics problem, please contact us in time

2.Q: How do I order?

A: If you can visit our company, we can fix all technical details

quickly by live discussion. We can also send you drawing so you can

specify needed configuration. Once the wire belt structure is

confirmed, we will sign contract. We accept T/T & L/C payment.

3.Q:How can I know that it is qualified and has passed the certificate?

A:This is simple, you just need to find an engineer to pass the technical verification agreed by both parties before receiving the goods.

P.S:If you require a unique belt or conveyor to deliver the best conveyor performance, we will not hesitate to design and deliver a totally customised solution for your application. Our aim is your complete satisfaction with the performance of our products. We are confident we can provide the right belt, sprockets and other components you need.