Qingdao KaFa Fabrication Co., Ltd. |

|

Verified Suppliers

|

|

Long Life Span Well Designed And Fabricated Industrial Steel Construction One Stop Solution

Structural steel is widely used in the steel building field with the advantage of short construction period and lower total cost compared with traditional civil construction method. The steel structure fabrication is a multifaceted process that requires specialized knowledge, skills, and resources to complete successfully. To create structural steel beams, components, or equipment, a good metal fabricator follows a specific process:

Step 1: Ideation

The ideation stage can be as creative or as standard as the client desires. Whether you need components for platforms or straightforward caged ladders, we can adhere to your exact needs.

Step 2: Blueprint/Drawing Creation

During ideation, we will listen to you and draw up blueprints using specialized engineering software. You can come prepared with your own blueprints or drawings for this stage. Review our blueprints to verify correct requirements, code compliance, and specifications.

Step 3: Convert Blueprints Into Shop Drawings

We will convert project blueprints into shop drawings for the fabrication. The shop drawings and plans will adhere to the logistics of your project, such as deadlines and budget. Shop drawings are what the manufacturer uses to bring the blueprints to fruition.

Step 4: Cut and Drill Steel Beams

We will have special tools, such as saws, shears, lasers, punches, notches, and plasmas to cut and drill the steel beams according to project blueprints. At KAFA, we use advanced equipment and facilities to the process the steel components. This advanced equipment produces higher quality results, faster.

Step 5: Piece Etching

We will etch each piece with a unique part number and plate location. This makes final assembly on site fast, easy, and accurate, eliminating costly mix-ups and project delays.

Step 6: Component Assembly

Once finish cutting and forming the components of your project, we will weld and assemble the pieces. At this stage, the fabrication team will check to make sure all pieces assemble correctly and match order specifications.

Step 7: Custom Part Machination

If you request any custom metal fabrication, we will create custom parts at this stage. Custom parts are ideal when you need components to fit a specific structure or product. You may need custom part machination if standard looks or sizes aren’t right for your project, either in function or aesthetics.

Step 8: Complete Assembly

We will complete a full assembly of your project, if possible. In some cases, partial assembly may apply. Complete assembly ensures all parts of the order are present and functioning. Changes at this stage are rare and only occur if there has been a mistake in a previous step.

Step 9: Shipping Preparation

After a successful complete assembly, the team will disassemble the project and prepare components for either finishing or direct shipment. We should do this quickly and efficiently, packing the components in a way that makes project erection at the site easy.

Step 10: Component Finishing

If you request special paint, powder coat, sandblasting, or another finish, we will apply this last. Industrial assemblies often require a certain finish to prevent corrision. At KAFA, we have a paint room and cutting-edge powder coater to get the job done.

Step 11: Project Ships to Site

At this point, your project is complete! We will follow your previously agreed-upon shipping arrangement, sending your completed, disassembled components directly to your site location. We will provide tracking details to ensure your project arrives on time.

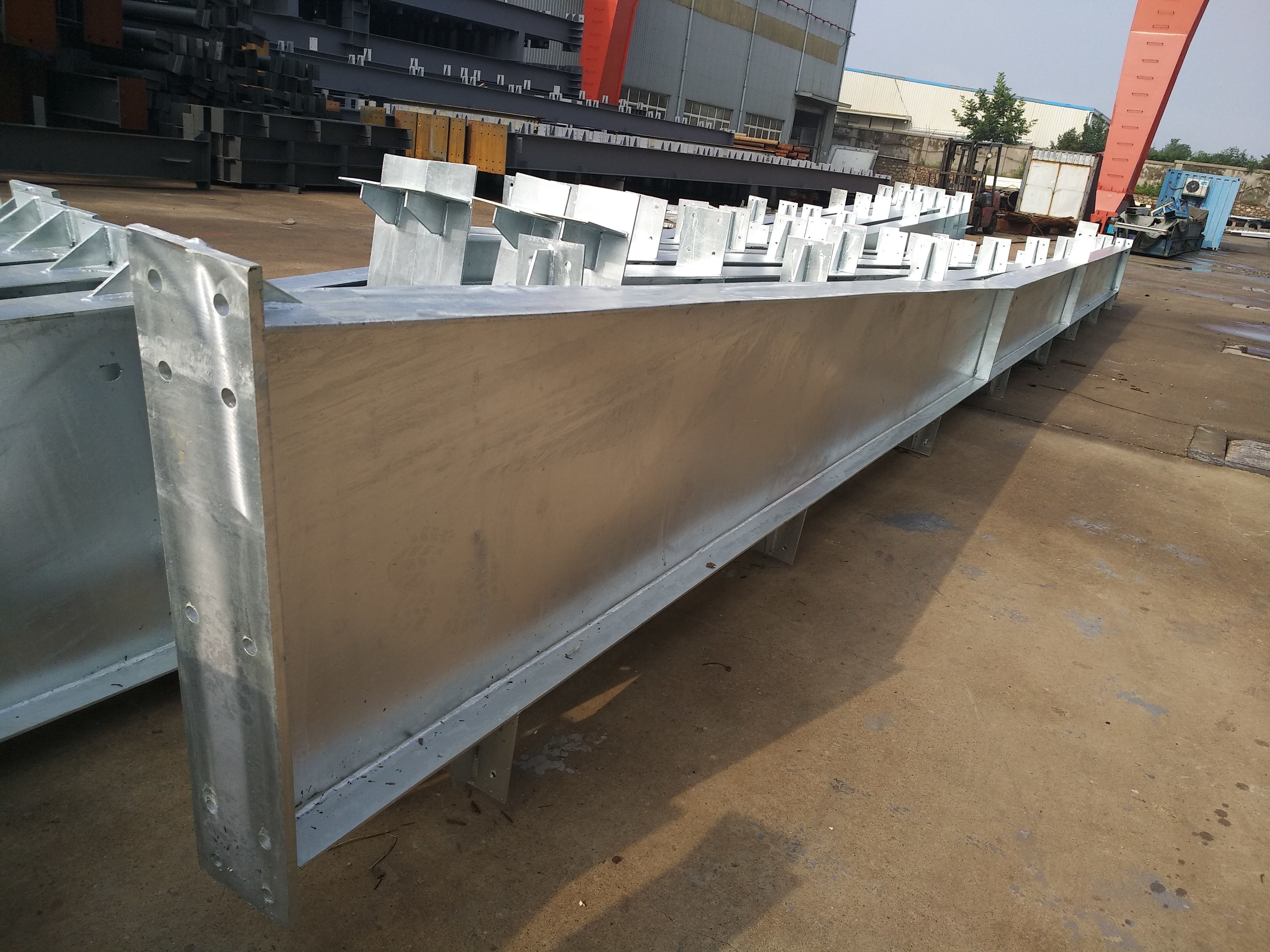

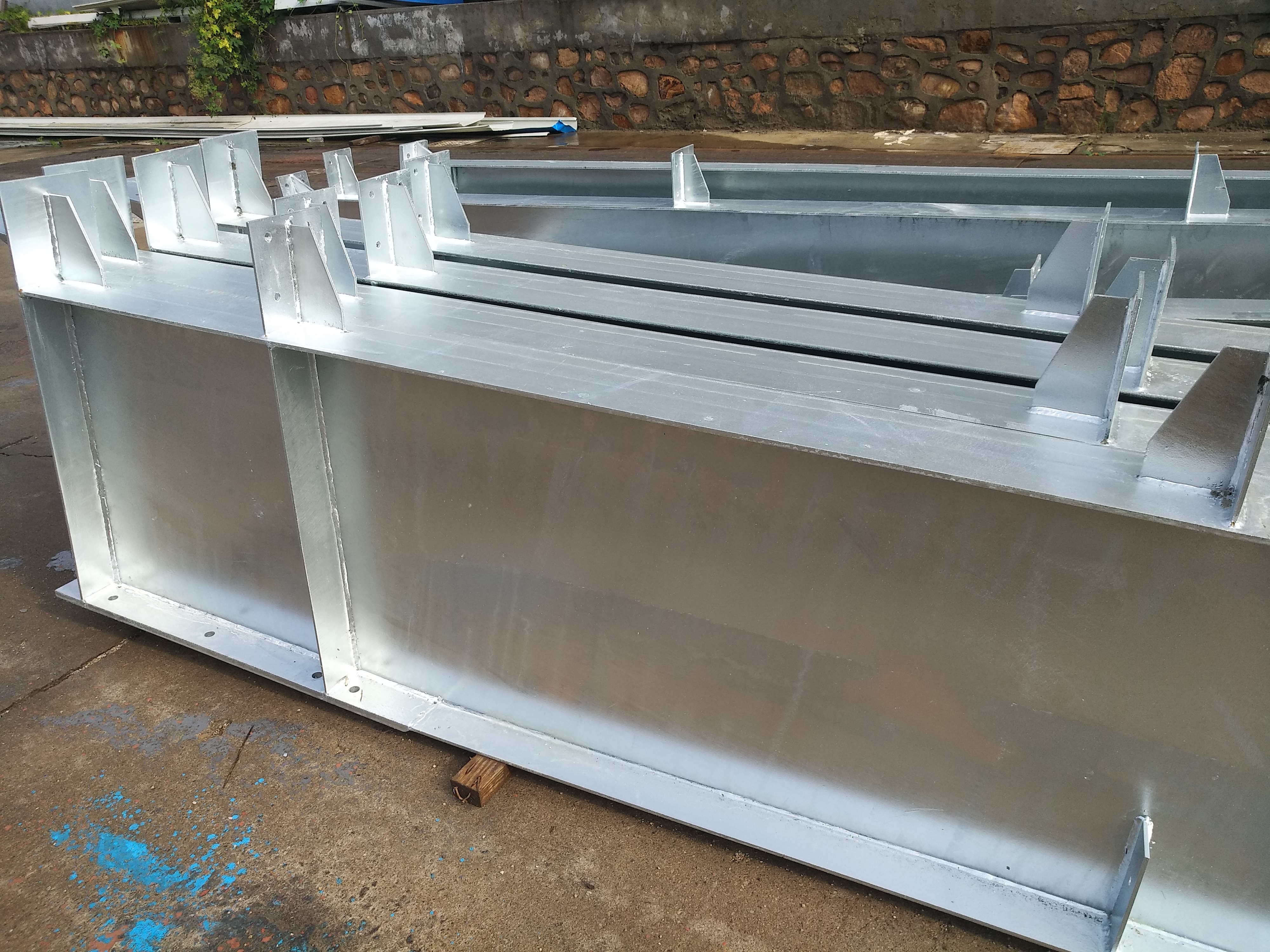

We fabricate kinds of sectional steel structures components, including but not limited:

Welded H section steel |

Pipe column |

BOX section steel |

Steel reinforced concrete column |

Lattice column |

Pipe truss |

| H beam truss |

Bridge |

Special Shaped steel member |

KAFA have highly trained and experienced professional fabrication and welding staff, and because of this, we are able to deliver a wide variety of fabrication services including a variety of steel sections, designed to meet your specific project requirements.

The fabrication procedure typically follows the below steps:

Measuring, cutting and welding the steel

Placing the holes and cleats in the correct position

Packaging and carefully loading in the right sequence

Dispatching to site and erecting if required.

Our work flaw:

Our factory view:

Technical team:

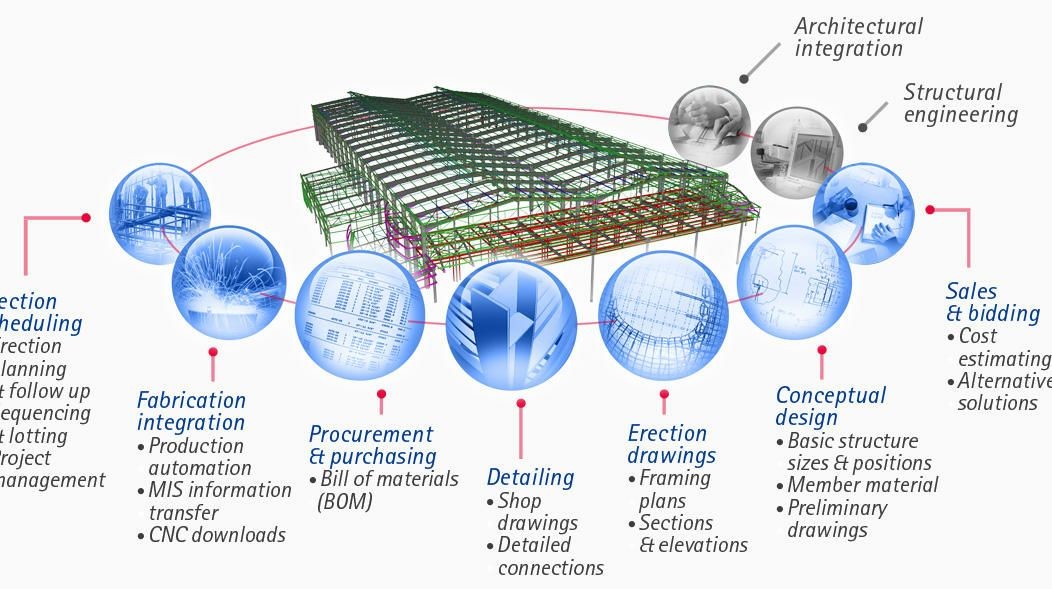

Through years of accumulation and deploitation, we have formed a complete set of building system solution. KAFA's exceptionally talented engineering staff have earned a solid reputation. They are all qualified engineers, with structural expertise and extensive design experience. Our design engineers, skilled with advanced CAD and TEKLA software, will provide you with most dependable and economical building structure. Design considerations may include such factors as seismic, wind and soil bearing loads in relation to supporting structures and foundations. In other applications: corrosion allowances, specific gravity, slosh effect and equipment loads may need to be addressed. Whatever your concerns, we will analyze and design to your specific requirements and environments.

We believe technology makes a difference. By utilizing 3D detailing, Material Requirement Planning Software and CNC processing equipment, we are able to produce accurate drawings quickly, purchase material efficiently and process your job precisely.

A combination of in-house, domestic and foreign resources, techniques and technologies are utilised to meet our clients’ design requirements. With our experienced and well equipped estimating and project design team we ensure that anything is possible.