QHHK Steel Structure |

|

Verified Suppliers

|

|

Steel beams, columns, and roofing materials are the main materials used in the construction of steel structure workshops, which are industrial facilities. These buildings have large, column-free interiors that are perfect for production, assembly, or industrial tasks. They provide adaptable layouts for machinery, storage, and workflow efficiency, with an emphasis on robustness, durability, and adaptability. Steel's resistance to environmental influences guarantees durability and security. These structures enable effective operations and provide flexible solutions for production needs, making them adaptable to a variety of sectors. These workshops, with their sturdy steel foundation, offer large, flexible rooms that can be tailored to various industrial needs. |

|  |  |

|  |  |

| Items | Specification | |

| Main Steel Frame | Column | Q345, Q355 Welded H Section Steel |

| Beam | Q345, Q355 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z purlin |

| Knee brace | Q235 Angle Steel | |

| Tie rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical&Horizontal support | Q235 Angle Steel, Round Bar or Steel Pipe | |

| Cladding System | Roof panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel / |

| Rock Cotton Sandwich Panel / Pu Sandwich Panel /Steel Sheet | ||

| Wall panel | same with the roof panel | |

| Accessories | Window | Aluminum Alloy Window / PVC Window |

| Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

| Rainspout | PVC | |

| Live load on Roof | In 50kg/Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | according to local climate | |

| Earthquake-resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Finishing Options | Vast array of colors and type available | |

| Paint Options | Alkyd painting, two primary painting, two finish painting | |

| (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized | ||

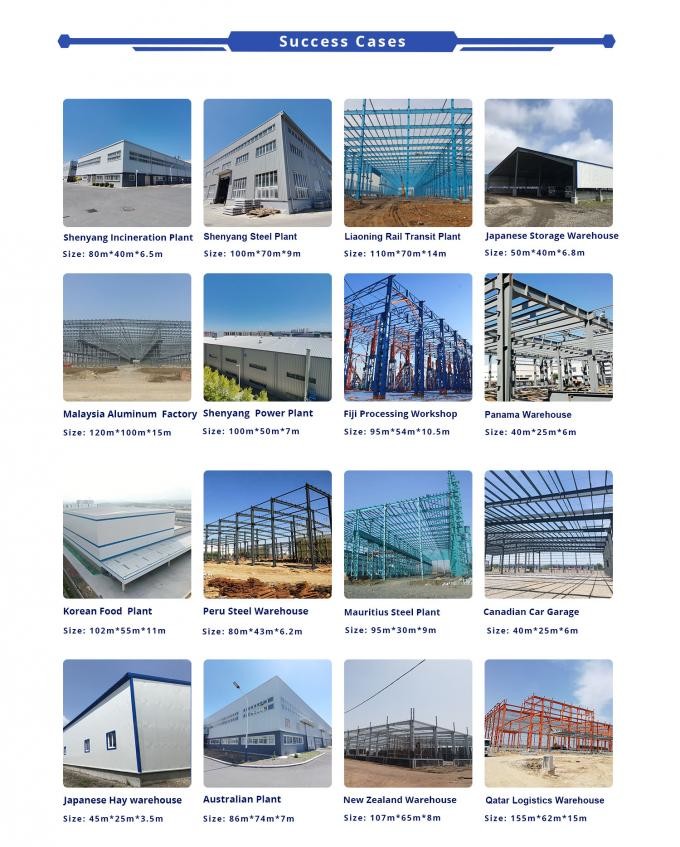

| QHHK is a 23-year supplier of steel structure warehouses, steel

workshop buildings, steel hangars, prefab steel gymnasiums, metal

garage buildings, steel structure poultry houses, and other large

steel buildings. QHHK provides one-stop steel structure services: design, fabrication, and installation guidance. QHHK has 2 modern factories in China. There are 4 production lines with a complete production equipment system. QHHK is a professional manufacturer of steel structure warehouse with 23 years experience, finished 2280 projects total of 1500000sqm. We have formed a complete set of efficient and professional customer service, production and processing, installation, and after-sales processes systems. We always insist on saving cost and time for our customers. Let customers be 100% satisfied, and 100% assured.We look forward to your visit and experience our high-quality services and products. |

We have been committed to the design of heavy steel buildings, the control of building quality details, the production

of steel components, and the installation of steel buildings for 23 years

Design Team

Mainly responsible for all kinds of industrial and civil building design, curtain wall design, and provide engineering consulting, technical guidance, the urban planning, the landscape design, indoor and outdoor decoration design, all kinds of engineering cost and other relevant construction engineering supporting design services. The company insists on the design of uniqueness, uniqueness and practical combine to make each one works become stand the test of time of classics. The company possesses strong design strength and professional design team, has several persons with senior design background of experts. The company partners, technical adviser, technical guidance are domestic famous structure expert, professor, national design master.

Our Service

1. We own the factory with advanced equipment and well trained

workers.

2. We control the cost for every step of production to keep the reasonable price .

3. We control production quality very strictly to keep ournone compensation record.

4. We guarantee 24 hours response and 48 hours solution provide service.

5. We provide free samples before orders, we accept trail order quantity before regular cooperations.

6. We ensure you get your order delivery in full within the agreed time period

7. Due to our selling power and exporting volumn, we have excellent freight rates with shipping lines.

8. We strive to always be fair and honest in our dealings with customers.

9. We strive to work together with customers to achieve much more than we can achieve alone.

10. We focus on growing business together with all of our

customers,Because we understand to take care of our own benefit we

firstly need to take care of customer's benefit .

11. Through our passion and commitment we aim to be a market leader

in all our key markets. To maintain our position as market leader

we must continue to add value in all that we do.

| Normally the goods will be shipped using 40’ open-top container and 40’ HQ container. If use 40’HQ, it need to do a steel pallet to pack the goods, then the whole pallet cargo will be pushed into container together, when you unload the goods, you will pull the whole pallet out of the container. In this case, the ocean freight will be cheaper but will increase the cost of pallet. Regarding the open-top containers, all the goods will be loaded one by one. In this case, the sea freight of 40’OT is higher than 40’HQ, but The steel pallet for 40’HQ needs to be charged. You can tell me your preference. |

Please kindly inform us of the information below if you are interested in our products.

1. Usage: For warehouse,workshop, showroom and etc.

2. Location: Which country or area?

3. Size: Length*width*height (mm)

4. Wind load: max Wind speed (kn/m2, km/h, m/s)

5. Snow load: max Snow height (kn/m2, mm)

6. Anti-earthquake level?

7. Brick wall needed or not?

If yes, 1.2m high or 1.5m high

8. Thermal insulation needed or not?

If yes, EPS, fiberglass wool, rock wool, PU sandwich panels will be

suggested.

If not, the metal steel sheets will be more affordable.

9. Quantity (unit) and size (width*height) of doors and windows

10. Crane needed or not?

If yes, quantity (units), max Lifting weight (tons), max Lifting

height (m).

1. Are you a manufacturing factory or trading company?

We are manufacture factory, located in Shenyang city, near to

Dalian port. We have 2 workshops from steel structure to wall

and roof sheet.

2. Can you provide free design?

Yes, we have 10 senior engineers with rich experience. You only

need to give me your idea, we will design it for you for free.

3. Can you offer competitive prices?

If you have no special requirement for the material, we all use

materials from big material manufacturing companies. We also

can design it according to your requirements. But no matter what kind of quotation mode, offering a reasonable price is our business objective.

4. How to install? Can you provide engineer to help?

We will provide detailed installations, like CAD, 3D Tekla, etc. Or

we will provide the engineers to help according to your

requirements.

Engaged in welding of steel structure work welders must pass the examination and obtain a certificate. The holder welder must weld in passing the examination and approval within the scope of the project.

2. Fastener connection requirements

Steel structure fabrication and installation of units should be in accordance with the provisions of the high-strength bolts respectively connected with the friction surface of the anti-slip coefficient test and retest, The component friction surface site should be dealt with separately anti-slip coefficient test, and the results should be consistent with design requirements.

3. Steel structure assembly and installation of steel structure requirements

(1) of H-type steel welding seam splicing spacing and the web of the seam shall not be less than 200 mm.

(2) and crane beam crane truss installation in place should not be deflection.

(3) multi-section column installation, each column positioning ground control axis should lead directly, not from the axis of the lower column guide, to avoid too large error accumulation.

(4) the steel grid structure after the completion of the total spell and roofing project should be finished to measure the deflection, the deflection and the measured value of 1.15 times can't exceed the design value.

(5) coating, coating times, and coating thickness shall comply with the design requirements.

(6) the thickness of coating coated thin type fireproof coating shall conform to the requirements of the design about the fireproof limit.

4. Electric single girder crane technical parameters

LD - type A electric single girder bridge crane and CD1, MD1 type electric hoist necessary use, become a light rail running a small crane.

This product is a general-purpose crane, for mechanical manufacturing, assembly workshops warehouses, and other places.

As with the Motor Grab spreader, it handles and transportation of bulk goods. This product is suitable for lifting weights 1, 2, 3, 5, and 10 tons, 22.5 meters span 7.5-.

The crane control mode with the ground (divided into wired and wireless two), control room control, for users to select.

This product is not flammable, explosive in medium or large humidity with acid, alkali gases places of work, is not suitable for lifting and transporting molten metal, toxic and flammable work.

This product series is a series of products of electric single girder cranes that adopt the international advanced standard manufacturing. The machine has the advantages of a novel structure, good technology, operation flexibility stable, safety, and reliable.