RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

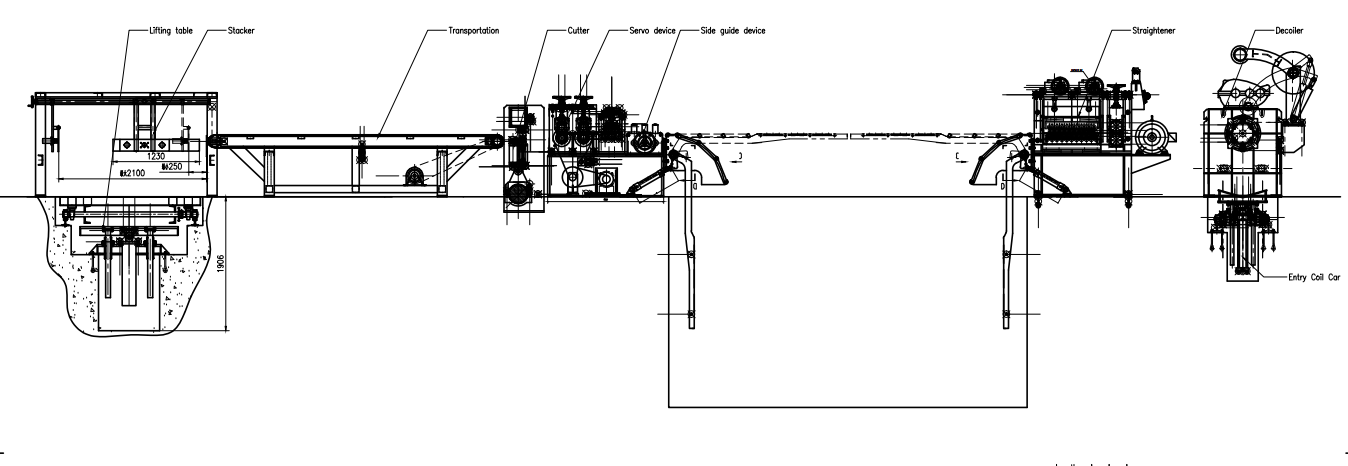

High speed cut to length machine

The cut to length line is used for decoiler, leveling, sizing and cutting the metal coil into the required length and stacking it. It is suitable for cut-to-length cross-cutting operations for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

Types of the cut to length machine:

1. According to the thickness of the metal plate, it is divided into the thin plate cross-cutting line (processing thickness 0.1-3.0mm) and the thick plate plate line (processing thickness 3.0-6.0mm).

2. According to the cut to length metal material, it can be divided into copper strip cut to length line, stainless steel cut to length line, cold plate cut to length line, silicon steel cut to length line, and tinplate cut to length line.

3. According to the degree of automation, it can be divided into automatic cut to length line and semi-automatic cut to length line.

4. According to the speed, we have slow speed cut to length machine and high speed cut to length machine.

The cut to length production line is mainly composed of feeding trolley, decoiler, leveling machine, feeding mechanism, shearing machine, conveying device, stacking device, etc. The production line can be equipped with a slitting machine to cut the sheets into the required width and cut to length and stack them. It is a high-performance product integrating machinery, electricity and hydraulics.

High degree of automation, simple and reliable operation. The precision of fixed length is high, the flatness of the sheet is high, and the stacking is neat.

In the following parts, I will show the elements one by one:

| No | Name | Unit | Parameter |

| 1 | Control model | PLC frequency control | |

| 2 | Applied to | Stainless steel | |

| 3 | Thickness | mm | 0.4 -0.9 mm or customize |

| 4 | Width | mm | 200-1250 or customize |

| 5 | ID | mm | Φ480-520 |

| 6 | OD | mm | ≤1400 |

| 7 | Coil weight | Ton | ≤5 |

| 8 | Diameter of leveling roller | mm | 65 |

| 9 | Distance of leveling rollers | mm | 70 |

| 10 | Number of leveling rollers | 19 | |

| 11 | Material of leveling roller | GCr15 | |

| 12 | Material of cutter blade | 6CrW2Si | |

| 13 | Speed | m/min | ≤50 |

| 14 | cutting speed | pieces/min | 50 pieces(per meter) |

| 15 | Direction of feed material | from left to right | |

| 16 | Length tolerance | ≤±0.5mm | |

| 17 | Diagonal tolerance | ≤±1 mm | |

| 18 | Power | 380V/3PH/50HZ (customized) |

Working Flow of the cut to length machine:

Hydraulic decoiler

Supporting steel rolls and uncoiling, the expand and shrink plant thicken to 20mm.

the coil can ensure the expand range φ480-520 of the coils inner diameter

It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter of coils. It is equipped with the cantilever .The coil weight can be up to 5T.4KW motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension. Mechanical structure: the process is weldedby steel plate and steel.

Sixfold pre-leveling machine (45KW AC)

It is designed as the six fold leveling machine which can improve the sheets surface quality.

Structure: It is consist of two rows leveling rollers, two rows middle supporting roller,one group supporting rolling wheel, drive devices, two pinch roller and frame,etc. Both sides of each rolling wheels are driven by pinwheel bearing. 19 leveling rollers has the drive and the diameter of the rollers is 65mm and the distance between the rollers is 70mm. 19 pieces middle rollers’ diameter is 65mm,roller distance is 70mm, 2 pinch rollers surface is covered with polyurethane to prevent the sheets from being scratched. The supporting roller wheels are divided into three groups for both and up and down .

The function of supporting roller: make the even rollers receive the balanced force and reduce the friction of the leveling rollers. The working rollers use electric machine to adjust the upper and lower gap with 2 hand wheel to make sure the even quality.

Drive model: all the independent rollers and gear box are driven by 45kw frequency control electromotor machine.

As to the stacker and convey table, we can not list all of them here. If you need to know more information, please contact us at any time.

When you need the accurate quotation, please tell us the following information:

1. What is the material thickness and coil width.

2. How much speed is better for you.

3. What is the Max coil loading weight.

4. How much of the coil Max weight.

5. As to the accuracy either in cutting and leveling, please let us me and then we can give better design.

Welcome to contact us at any time.