RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

Rolling shutter door interlocked tube rolling forming machine

Rolling shutter door interlocked tube rolling forming machine is designed to make the tubes by the interlocked types and rolling forming principle. The use of octagonal pipes or interlocked tube mainly involves fields such as construction engineering, mechanical equipment, transportation, and aerospace.

In construction projects, octagonal pipes are mainly used as protective pipes for wires and cables, as well as for drainage pipes. The design of its eight end corners makes the pipeline connection more firm and tight, while also having good compressive and tensile properties, which can effectively protect wires and cables from external damage. In addition, due to its good structural stability and ability to withstand significant pressure and weight, octagonal pipes are also commonly used as support and load-bearing components, such as in the construction of bridges, high-rise buildings, and other engineering projects. Here are some drawing profiles for your reference:

The principle of forming process:

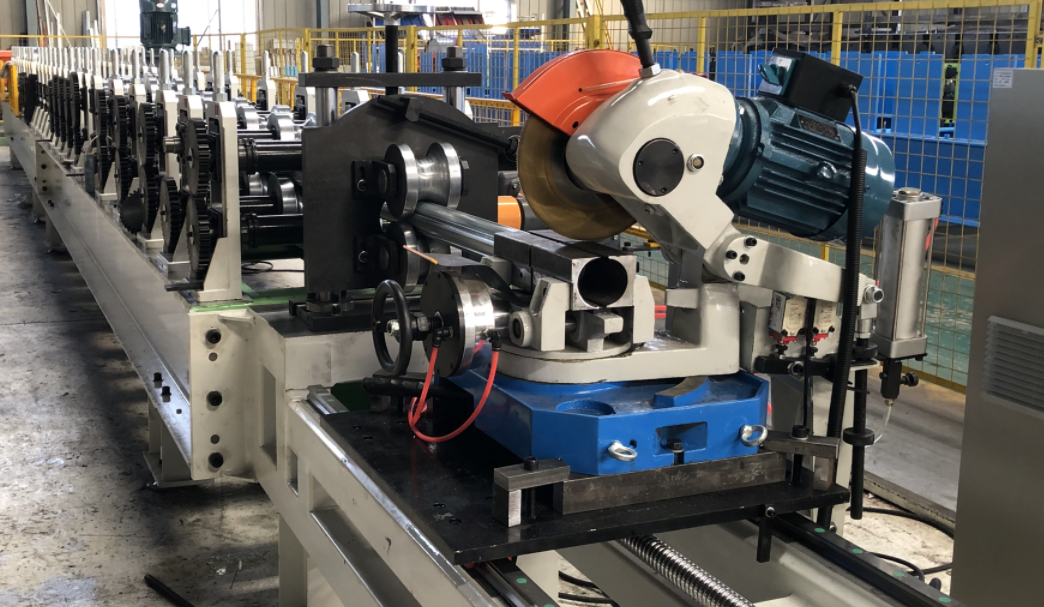

Rolling shutter door interlocked tube rolling forming machine:

Rolling shutter door interlocked tube rolling forming machine:

Machine parameters:

Feeding materials:0.60mm×W, PPGI/PPGL, G250-350Mpa

Machine frame type:open style individual structure with welded platform by beam

Forming station:19 stations roller forming +1 stations roller punching + 1 station rectifying

Main shaft material:45# Round steel, heat treatment,HRC40-45, Φ70mm /

Rollers material:Gcr15, ball bearing steel, quenching HRC 52-55C°, chrome coating 0.05mm /

Bearing:Chinese famous brand ZWZ / HRB brand

Transducer:V1000 YASKAWA ,Japan

Operation system: Operation cabinet + Emergency remote control unit

PLC Siemens brand: Encode/Omron, Japan brand

Other electricians/Schneider and Omron brand.

More details of interlocked tube rolling forming machine:

For making sure the interlocked part more beautiful, there will be lots of side roller designed.

For the shearing part, you can use the disk shearing or cold disk shearing with the servo motor control.

Here is the machine working videos for your reference: