RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

Stainless Steel and HDG Unistrut Strut Channel rolling forming machine

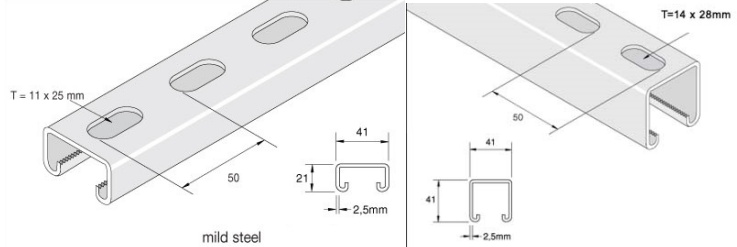

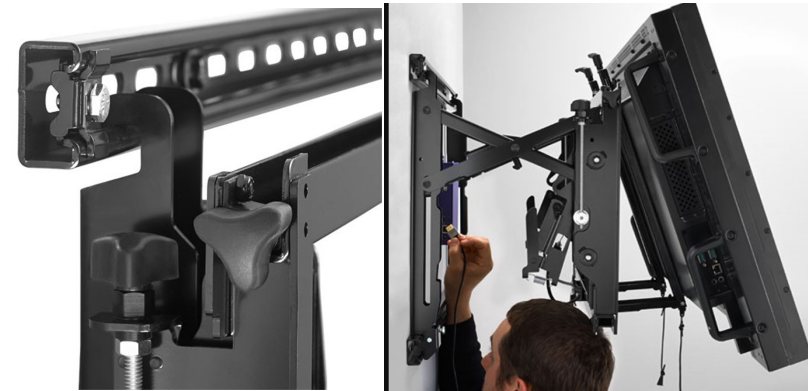

Stainless Steel and HDG Unistrut Strut Channel rolling forming machine is designed to make the Unistrut Strut Channel in batch fully automatically. As to the galvanized steel range of struts from Unistrut, these Unistrut slotted channels and plain channels have been specially designed as support systems for mechanical, electrical and plumbing installations which can be attached to existing steel work or concrete inserts, or directly into walls, ceilings, and floors. This range of durable struts is available in either slotted or plain, to accommodate for a range of applications. These channels are also compatible with Unistrut’s metal framing system accessories for quick and easy assembly, saving you time and effort. Here are some pictures about how they work.

Stainless Steel and HDG Unistrut Strut Channel rolling forming machine:

If the material is stainless, where should be different when design machines:

1. As the stainless steel 304 especially, the unistrut Strut channel machine needs more roller stations. As stainless steel is hard to bend and fix shape.

2. As to the punching part, it needs also more bigger motor to make the profile punching holes neat and clean.

3. As to the shearing part, we will use the cold disk shearing saw not hydraulic shearing to make sure the shearing is neat and no shearing burr.

The what can benefit you if you use stainless steel.

1. It will save time of painting.

2. And long time to use.

Stainless Steel and HDG Unistrut Strut Channel rolling forming machine parameters for your reference:

| The machine is composed by the following elements | |||

| No | Item Name | Notes | |

| 1 | 3 Ton Hydraulic decoiler | ||

| 2 | Leveling Machine | ||

| 5.5KW of seven rollers Servo coil feeder 4KW | |||

| 3 | 80 Ton punching station YangLi | If you want to change to normal one, please let me know. This one in the market price is 22000 USD. | |

| Punching molds 6 holes | 1 set | If you want to change, we can adjust | |

| Air compressor system | 1 set | Flow rate 0.5m2/min; pressure 0.7Mpa | |

| 4 | Roll Forming 44KW | 1 set | Gearbox transmission, If you want to update to chain transmission, we can change for you. |

| 5 | Servo coil feeder price | 1 set | If you feel speed is very important, we can use flying no-stop cutting device. |

| 6 | PLC Control System | 1 set | Brand Semen |

| 7 | Hydraulic Station | 1 set | Yuken Serious. |

| 8 | Run-out Table | 1 set | |

Servo flying tracking shearing system with gearbox transmission:

1). Servo motor power: 15kw

2). Oil pump station 1 set

3). Cutter material: Cr12 mold steel with quenched treatment

4). Hydraulic cutting after forming, no distorting or wasting. High level safety factor.

As to how to adjust sizes for different sizes, we have following options:

By adjust 6 rollers to change the size like the following pictures:

There are some easy to adjust spacer, simple make the flexible spacer more easy and then adjust the spacer for different sizes.

From the size 41x41 to 41x21, you need to adjust 10 rollers station spacer.

From sizes 41x41 & 41x21 to 50x50, you need to adjust all roller station spacer.

And the molds we will design as the separated molds, so one machine can make all those sizes without changing rollers. But the cutting blades, you need to adjust a little bit.

If you have engineer who know how to adjust spacer, we can design machine with more spacer and some rollers and then you can make different profiles by one machine.

If you do not have experience on this, we can design by fast change type.

For more information, you can contact us at any time.