Yuhong Group Co.,Ltd |

|

Verified Suppliers

|

|

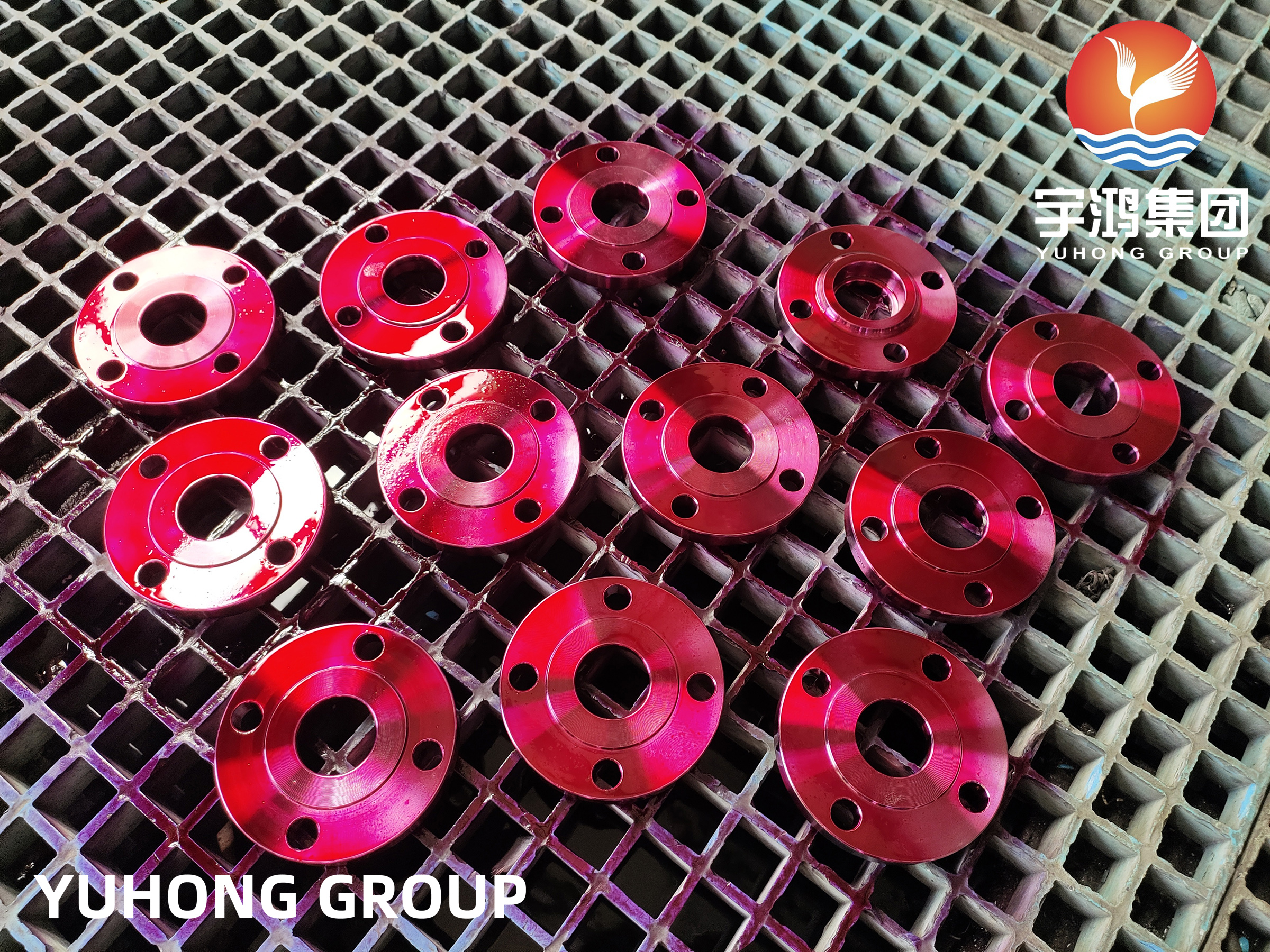

We are one of the largest engineering piping product suppliers in China, our products include steel pipes/pipes, pipe fittings, flanges. After more than 20 years of development, we have accumulated many customers all over the world, and Yuhong products have also won unanimous praise from customers.

| Specifications | Stainless Steel 316L Flanges |

| ASME B16.5 Stainless Steel 316L Flanges size range | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Stainless Steel 316L Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Stainless Steel 316L Flanges Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Stainless Steel 316L Flanges Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Stainless Steel 316L Flanges Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Stainless Steel 316L Flanges Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Stainless Steel 316L Flanges Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Stainless Steel 316L Pipe Flanges Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc | |

| Production technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Most common types of Stainless Steel 316L Flanges | Lap Joint Ring Flange (LJRF), Stainless Steel 316L Flanges |

| Socket Weld Ring Flange (SWRF), Stainless Steel 316L Flanges | |

| Slip-On Ring Flange (SORF), Stainless Steel 316L Flanges | |

| Blind Ring Flange (BLRF), Stainless Steel 316L Flanges | |

| Threaded Ring Flange, Stainless Steel 316L Flanges | |

| Ring Type Joint Flange (RTJF), Stainless Steel 316L Flanges | |

| Weld Neck Ring Flange (WNRF), Stainless Steel 316L Flanges | |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Stainless Steel 316L Flanges Standard | ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange, ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, |

| BS Flange, EN Flange, API 6A Flange etc | |

| B.S: BS4504 , BS3293, BS1560, BS10 | |

| AS 2129: Table D; Table E; Table H | |

| ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings | |

| ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 | |

| ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 | |

| American standard (ANSI) | |

| German (DIN) | |

| British standard (BS) | |

| Any other specilised flanges | |

| DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 | |

| The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203;UNI2276 | |

| Key markets and industries for Stainless Steel 316L Flanges | Nuclear power (mostly seamless). |

| Petrochemicals and acids. | |

| Bitumen upgraders. | |

| Heavy oil refineries. | |

| Stainless Steel 316L Flanges Application | To Connect Pipe & Tubes in Petroleum, Power, Gas, Metallurgy, Shipbuilding Construction, Chemical etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

A182 F316L Flanfes Chemical Composition:

| C | Mn | Si | P | S | Cr | Mo | Ni | Ti | Fe |

| 0.0-0.07 | 0.0-2.0 | 0.0-1.0 | 0.0-0.05 | 0.0-0.02 | 16.5-18.5 | 2.00-2.5 | 10..-13.00 | - | balance |

A182 F316L Flanfes Mechanical Properties:

| Grade | Tensile Str(Mpa) min | Yield Str 0.2% Proof(Mpa) min | Elong(% in 50mm) min | Hardness | |

| Rockwell B max | Brinell max | ||||

| 316L | 485 | 170 | 40 | 95 | 217 |

Grade 316L, a low carbon version of the F316L pipe flange, is resistant to sensitization, also known as grain boundary carbide precipitation. As a result, Gr F316L is widely used for heavy-duty welded components with wall thicknesses over 6 mm. The austenitic structure in astm a182 f316l also gives this grade excellent toughness properties, which can be observed at low temperatures.

Compared to other chromium-nickel austenitic stainless steels, A182 F316L stainless steel has higher creep strength, stress rupture strength and tensile strength even at elevated temperatures. ss 316L flanges provide excellent performance in a wide range of atmospheric environments and in many corrosive media.

In general, werkstoff A182 F316L tends to be more resistant to corrosive media than grade 304 stainless steel. Although these stainless steel 316L flanges are subject to pitting and crevice corrosion in warm chloride environments and stress-related corrosion cracking at temperatures above 60 °C, the sa 182 F316L flanges are considered potable water resistant of. astm A182 Gr F316L has shown corrosion resistance in drinking water, holding up to about 1000 mg/L of chloride at ambient temperature and further reducing to about 500 mg/L at 60 °C.

Flange ASTM A182 F316L is generally considered to be the standard "Marine Grade Stainless Steel". But astm A182 grade F316L is not resistant to warm sea water. 316l stainless steel flange material does tend to exhibit surface corrosion in many marine environments. This surface corrosion usually manifests as brown staining, especially in relation to cracks and rough surface finish.

316L stainless steel flanges exhibit good oxidation resistance in intermittent applications up to 870 °C and continuous duty up to 925 °C. Continuous use of flange astm A182 f316l in the temperature range 425 °C - 860 °C is not recommended if subsequent water corrosion resistance is important in any application. Many 316L stainless steel flange manufacturers state that this alloy is more resistant to carbide precipitation and can be used in the above temperature range.