ASME SA516 Gr.70N STATIONARY TUBESHEET

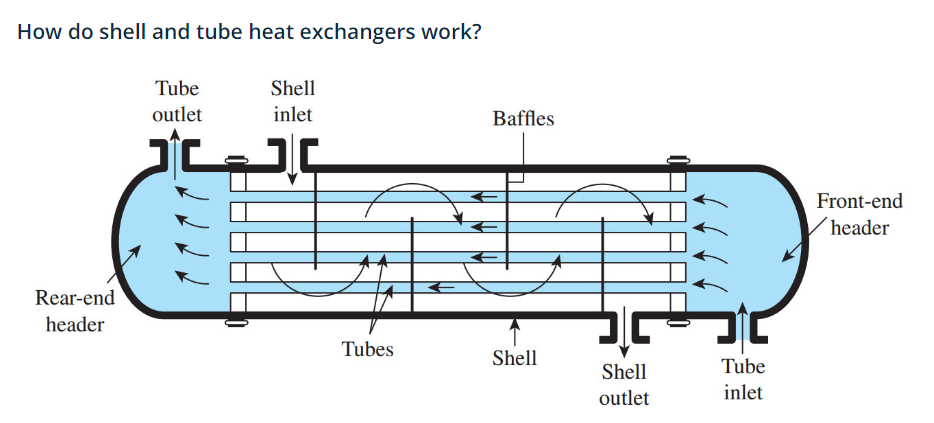

Fixed tube plate heat exchanger refers to a shell and tube heat

exchanger in which the tube plates at both ends of the tube bundle

are fixedly connected to the shell by welding. After the tube plate

and the shell are welded, it can also serve as a flange and be

connected to the pipe box flange with bolts. The advantage is that

the structure is simple and the inner diameter of the shell

required is the smallest while ensuring equal heat transfer

surfaces.

Tube sheets are key components of various heat exchangers and

shell-and-tube vessels. Its main purpose is to provide support and

sealing to the tube bundle. Within cylindrical or rectangular

tubes, there are different types of tubesheets, each type designed

for a specific application. Here are some common segment types and

their detailed descriptions:

1.Fixed tube sheet: Description: The fixed tube sheet is fixed in

the shell of the heat exchanger and welded or welded into the hole

of the fixed tube sheet. They will not move relative to the tube

sheet and the expansion between the tubes and the shell is very

small.

2. Floating tube sheet:

Description: The design of the floating tube sheet allows the tube

bundles to expand and contract freely with temperature changes. The

tube sheet is not connected to the shell by direct welding:

however, it can be moved within certain limits. Use hs desien when

stgticat temptre vanaton is present to help prevent damage to pipes

and pipe-to-tubesheet joints.

3. U-shaped tube bundle:

Description: In a U-tube bundle heat exchanger, the tubes are bent

into a "shape." The ends of the U-shaped tubes are fixed or welded

to a single tube sheet. This configuration is typically used in

applications where thermal expansion and contraction need to be

accommodated, but the connector needs to be removed for

maintenance.

4. Floating head tube plate:

Note: In some shell and tube heat exchangers, the other end is

closed by a floating head tube heat exchanger, and one end of the

shell is closed by a fixed tube sheet. The floating head can move

axially to accommodate the thermal expansion and contraction of the

tube. This design is common in Rappe heat exchangers.

5.Fixed tubesheet (with expansion joint description) If the

temporary connection between the tube and shell is important and a

floating tubesheet may not be practical, expansion joints may be

incorporated into the design of the fixed tubesheet. These

expansion joints allow a certain amount of movement while

maintaining a strong connection between the tube and tubesheet. The

choice of tubesheet type depends on a variety of factors, including

the specific application, temperature and pressure requirements,

and the need to accommodate thermal expansion and contraction.

Proper selection and design of tubesheets is critical to ensuring

efficient and safe operation of heat exchangers and pressure

vessels

The characteristics of fixed tube plate heat exchanger are:

1. The bypass seepage is small;

2. Forgings are used less and cost is low;

3. No internal leakage;

4. The heat transfer area is 20% to 30% larger than that of the

floating head heat exchanger.

The disadvantages of fixed tube plate heat exchangers are:

1. The temperature difference between the shell and the pipe wall

is large. When t ≥ 50°C, an expansion joint must be installed on

the shell;

2. Temperature difference force is easily generated, and

temperature difference stress is easily generated between the tube

plate and the tube head, causing damage;

3. The shell side cannot be cleaned mechanically;

4. After the pipes are corroded, they will be scrapped together

with the casing, and the equipment life will be short.